36

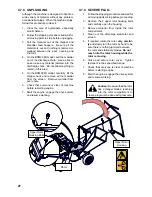

ChopBlock:

The ChopBlock is an assembly of breaker tabs bolted in at the bottom of the upper rotor housing. The

shredder knives pass through the chop block, and helps to break the material into smaller pieces and

turn it into mulch. Inspect the chop block for damage such as gouges, bent, or missing teeth. A damaged

chop block should be replaced. If it teeth are showing wear, remove and rotate the chop block.

1.

Ensure the engine is off (ignition switch is off

and the fuel valve is closed).

2.

Remove the 2 bolts that hold the upper rotor

housing, and carefully open the rotor housing.

3.

Remove the 2 bolts that hold the chop block to

the housing, remove the chop block.

4.

Reverse the steps to install the new chop

block.

Chop Block

Bolts

Chop Block

Machine is shown with guard removed

for illustrative purposes only. Do not

operate machine with guard removed.

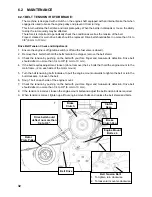

Ledger Blades:

Each machine is equipped with a ledger (stationary) blade that acts as a shear for the moving rotor

blades.

The ledger blade is designed with 4 usable corners. When the corner facing the rotor blade rounds

over, remove the blade and re-install with a different corner facing the rotor blade. It is recommended

that the clearance between the rotor and stationary blades be set and maintained at 1/32 to 1/16 " (.76

- 1.52 mm) to obtain the best performance.

1.

Ensure the engine is off (ignition switch is off

and the fuel valve is closed).

2.

Remove the 2 bolts that hold the ledger blade

to the ledger mount, remove the blade.

3.

Rotate the blade and replace or replace with

new or re-sharpened blade.

4.

Hand tighten the bolts and set the clearance

between the ledger and rotor blades at

1/32 - 1/16" (.76 - 1.52 mm). For fast and

easy setting, use our chipper clearance

setting tool, available from your dealer (see

accessories)

5.

Tighten down bolts as specified in the torque

chart

Ledger Blade

Ledger Blade

Bolts

WARNING