7.6 Drive Belt Replacement

The chipper has a centrifugal clutch mounted on the engine

shaft used to drive the rotor plate sheave. When the drive belt

is in disrepair or loose, the ability to efficiently drive the rotor

may be affected. Therefore, it is important to periodically check

belt condition and tension. A frayed, cracked or worn drive belt

should be replaced.

IMPORTANT! If changing or removing drive belt, always set

correct belt tension. Make sure engine and rotor sheaves

align properly.

Check drive belt tension every 100 hours of operation.

Make sure the engine is off and components are cool to touch

beforehand.

1.

On the side of the chipper, remove the belt guard.

2.

Loosen (do not remove) the four engine mount bolts—two

per side.

3.

Turn the belt tensioning bolt counterclockwise to loosen the

belt. Loosen enough so that the engine can be slid back,

and the belt can be removed.

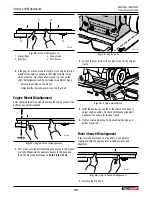

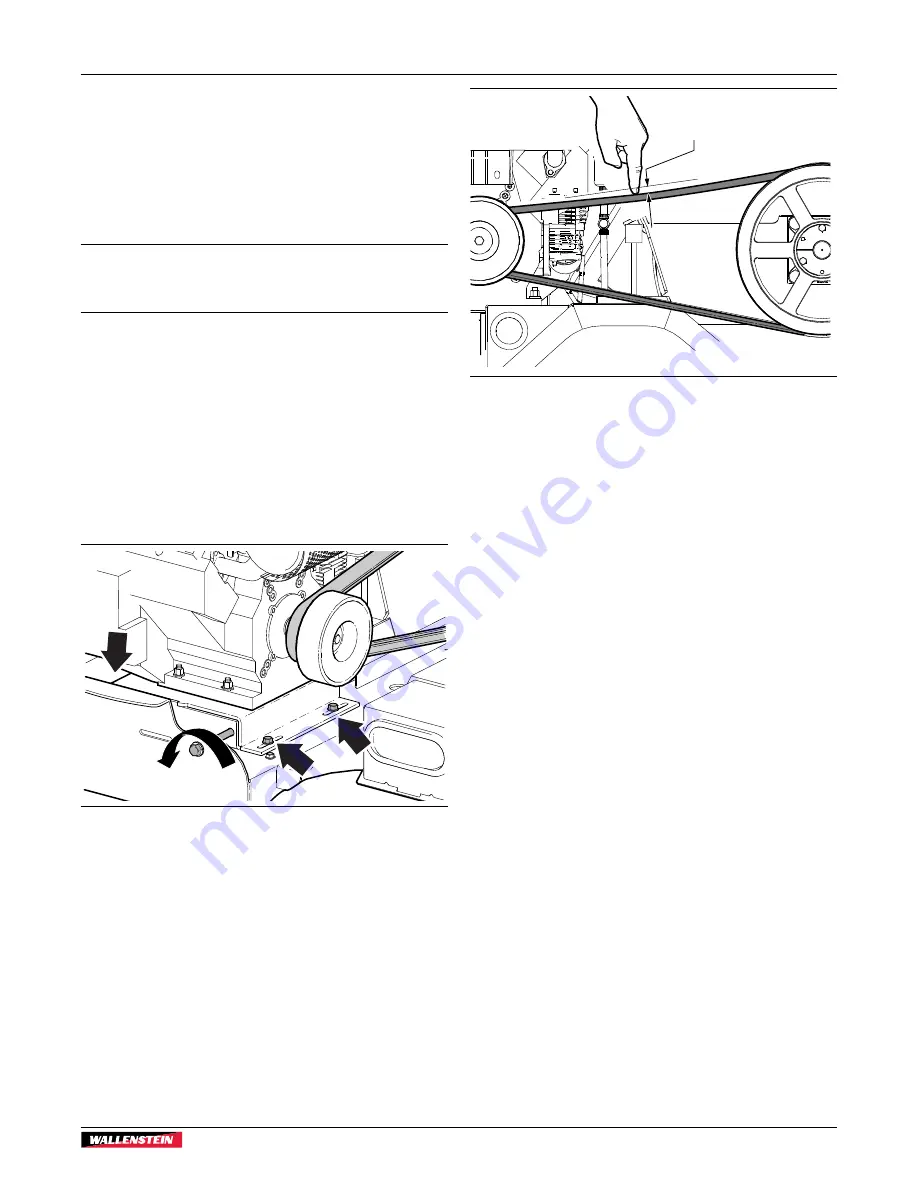

01122

Fig. 28 –

Drive Belt Tension Adjuster Bolt

4.

Install the new belt and slide the engine forward.

Tensioning

For accurate measurement use a drive belt tension gauge. If one

is not available, the following method can be used.

5.

Turn the belt tensioning bolt clockwise pulling the engine to

tighten the belt.

6.

Use your hand to check belt deflection by pressing on

the top, center of the belt. Correct belt tension is when it

does not deflect more than 1/2–5/8" (12–16 mm). Adjust

accordingly.

1/2"–5/8"

(12–16 mm)

01123

Fig. 29 –

Rotor drive belt tension

7.

Turn adjuster accordingly. Be aware of belt alignment when

adjusting belt tension. See

Alignment

to follow.

8.

When belt tension is correct, tighten all four engine mount

bolts.

9.

Reinstall the belt shield.

10.

Recheck belt tension after 10 hours of operation.

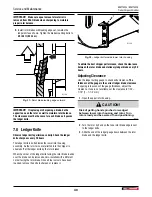

7.6.1 Alignment

Observe drive belt alignment every 8 hours of operation.

For accurate measurement use a laser alignment tool. If one is

not available, the following method can be used.

The maximum offset (misalignment) is 1/32" (1 mm).

1.

Remove the belt guard.

2.

Place a straight edge along the inner face of the engine

clutch and back side of the rotor sheave. Check the space

between the drive belt and the straight edge. The gap

should be even along the length of the straight edge.

BXMT4224 / BXMT4238

Trailer Chipper-Shredder

Service and Maintenance

37

Summary of Contents for BXMT4224

Page 51: ......

Page 52: ...www wallensteinequipment com...