01165

1

2

4

3

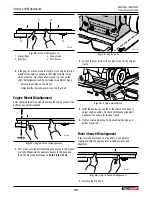

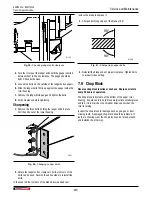

Fig. 30 –

Drive Belt Alignment

1. Straight Edge

2. Drive Belt

3. Engine Clutch

4. Rotor Sheave

3.

If the gap is not even along the length of the belt, determine

whether the engine is square to the chipper frame. It may

also be that the rotor sheave has moved in or out on the

shaft. Belt alignment can be corrected two different ways:

-

Turning the engine on the mount

-

Adjusting the rotor sheave in or out on the shaft.

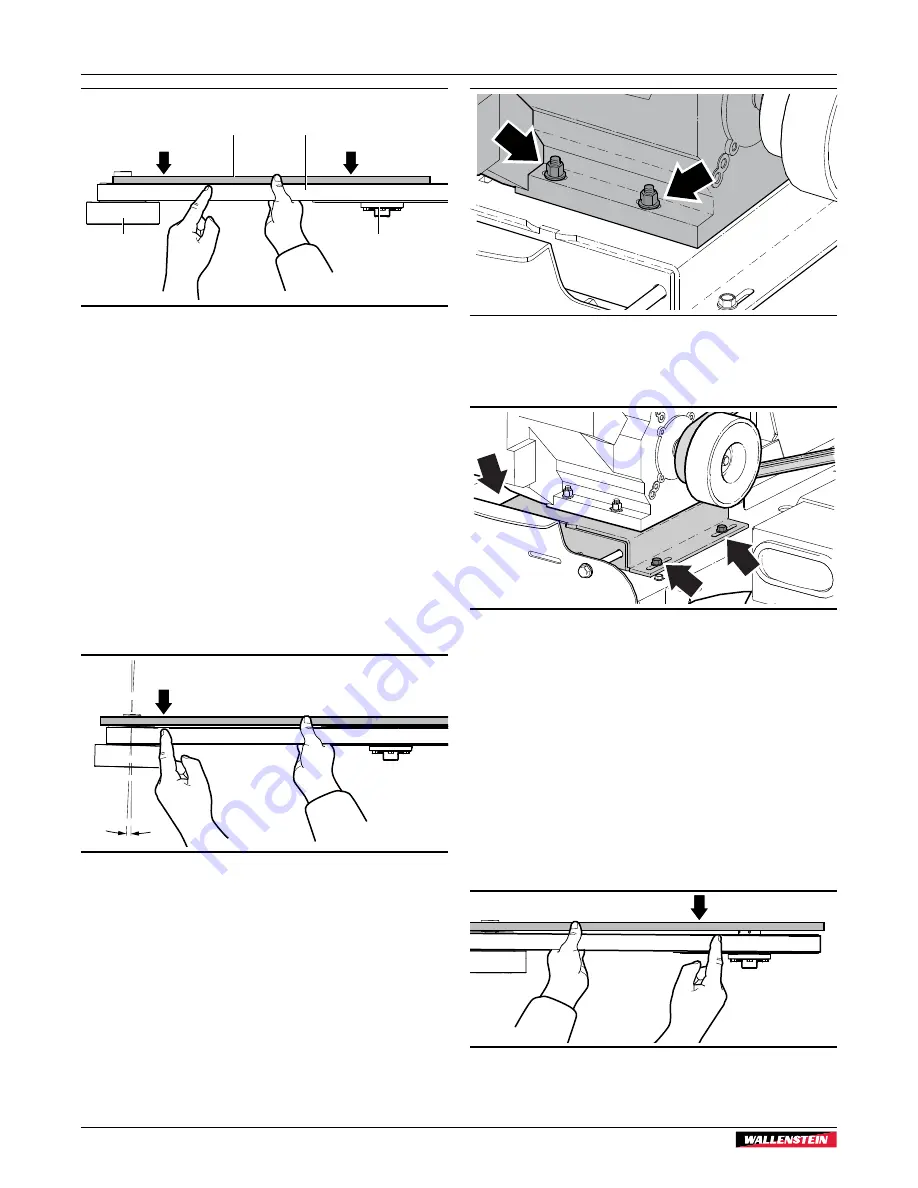

Engine Mount Misalignment

After changing the drive belt or loosening the engine mounts, the

belt may become misaligned.

01166

Fig. 31 –

Engine Mount Misalignment

1.

First, make sure the bolts fastening the engine to the mount

are tight. Make sure the engine is square to the base and

the bolts are properly torqued to

33 lbf•ft (45 N•m)

.

01170

Fig. 32 –

Engine bolts

2.

Loosen the four bolts on the engine mount to the chipper

frame.

01169

Fig. 33 –

Engine Mount Bolts

3.

Twist the engine to one side or the other on the base to

adjust engine position. Recheck belt/sheave alignment.

Repeat as necessary for the best result.

4.

Tighten engine mount bolts. Recheck belt tension and

adjust if required.

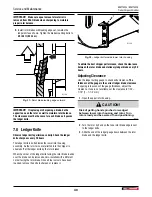

Rotor Sheave Misalignment

If the rotor sheave loosens on the shaft, it can become

misaligned with the engine clutch resulting in poor belt

alignment.

01167

Fig. 34 –

Rotor Sheave Misalignment

1.

Remove the drive belt.

Service and Maintenance

BXMT4224 / BXMT4238

Trailer Chipper-Shredder

38

Summary of Contents for BXMT4224

Page 51: ......

Page 52: ...www wallensteinequipment com...