IMPORTANT! Make sure equal amount of material is

removed from EACH blade when sharpening to maintain

proper rotor balance.

5.

Install rotor blades with leading edge out, towards the

ledger knife as shown. Tighten the blade mounting bolts to

45 lbf•ft (63 N•m)

.

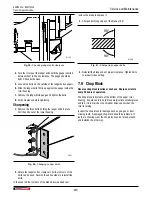

01124

Fig. 37 –

Rotor blade leading edge outward

IMPORTANT! If replacing or sharpening a blade, do the

opposite one on the rotor as well to maintain rotor balance.

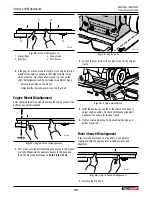

The clearance must be the same for each blade as it passes

the ledger knife.

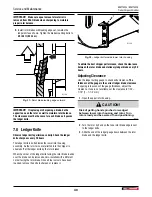

7.8 Ledger Knife

Observe ledger knife performance daily. Check the ledger

knife sharpness every 50 hours.

The ledger knife is bolted inside the lower rotor housing

assembly. As the rotor turns, material fed into the chipper is

sheared off at the ledger knife by the rotor blades.

When the corner of the ledger knife facing the rotor blade rounds

over, the blade can be removed and re-installed with a different

corner facing the rotor blade. Once all four corners have been

rounded, remove the knife to sharpen or replace it.

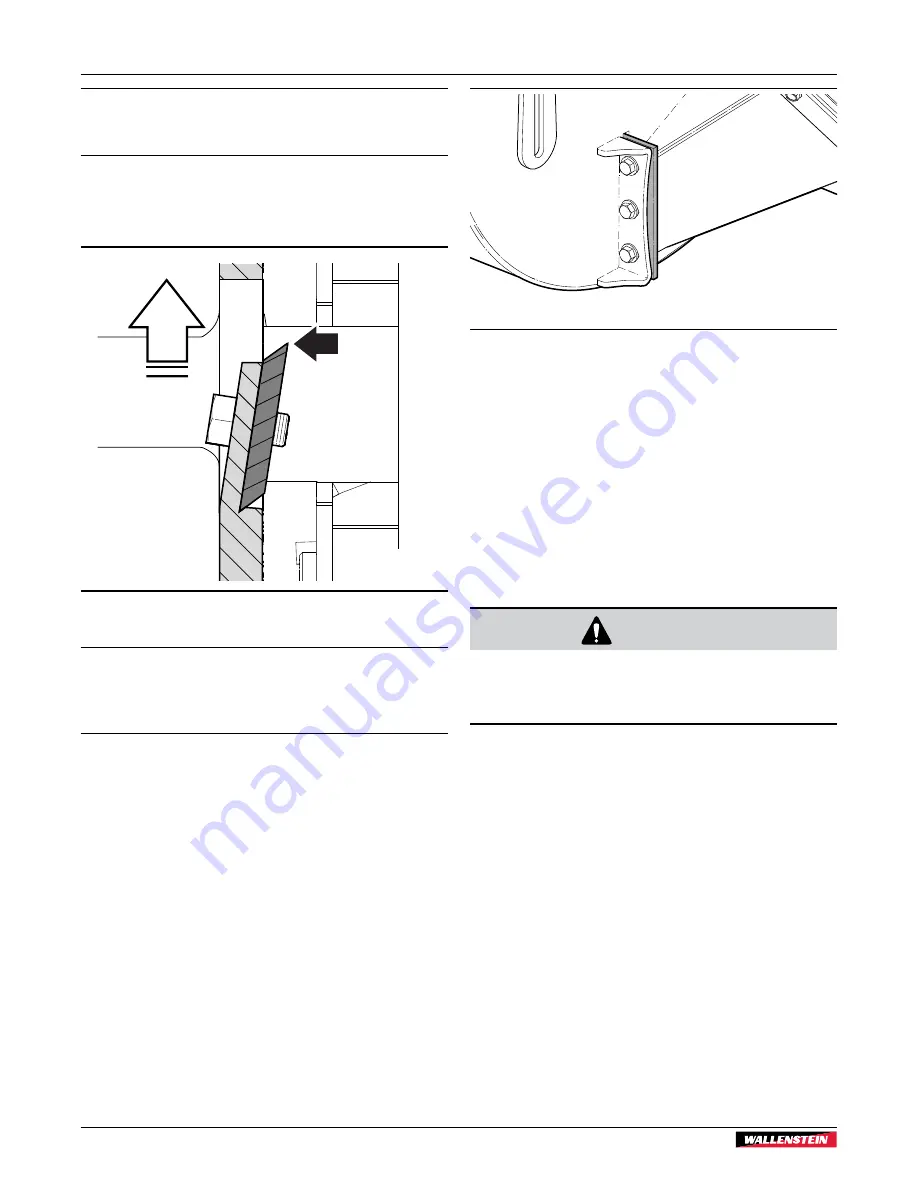

01129

Fig. 38 –

Ledger knife inside lower rotor housing

To obtain the best chipper performance, check the clearance

between the rotor blade and stationary ledger blade every 50

hours.

Adjusting Clearance

Use the ledger setting gauge to check knife clearance

. The

thickness of the gauge is the correct ledger blade clearance.

If spacing is in excess of the gauge thickness, adjust the

clearance. If one is not available, set the clearance to 1/32–

1/16" (1 – 1-1/2 mm).

1.

Open the upper rotor housing.

CAUTION!

Risk of getting hands pinched or wedged

between lower rotor housing and rotor. Turn

rotor slowly and be aware of hand positioning.

W032

2.

Turn the rotor by hand so that one rotor blade edge is next

to the ledger knife.

3.

Slide the end of the ledger gauge down between the rotor

blade and the ledger knife.

Service and Maintenance

BXMT4224 / BXMT4238

Trailer Chipper-Shredder

40

Summary of Contents for BXMT4224

Page 51: ......

Page 52: ...www wallensteinequipment com...