02318

Figure 34 –

Remove the engine guard

02320

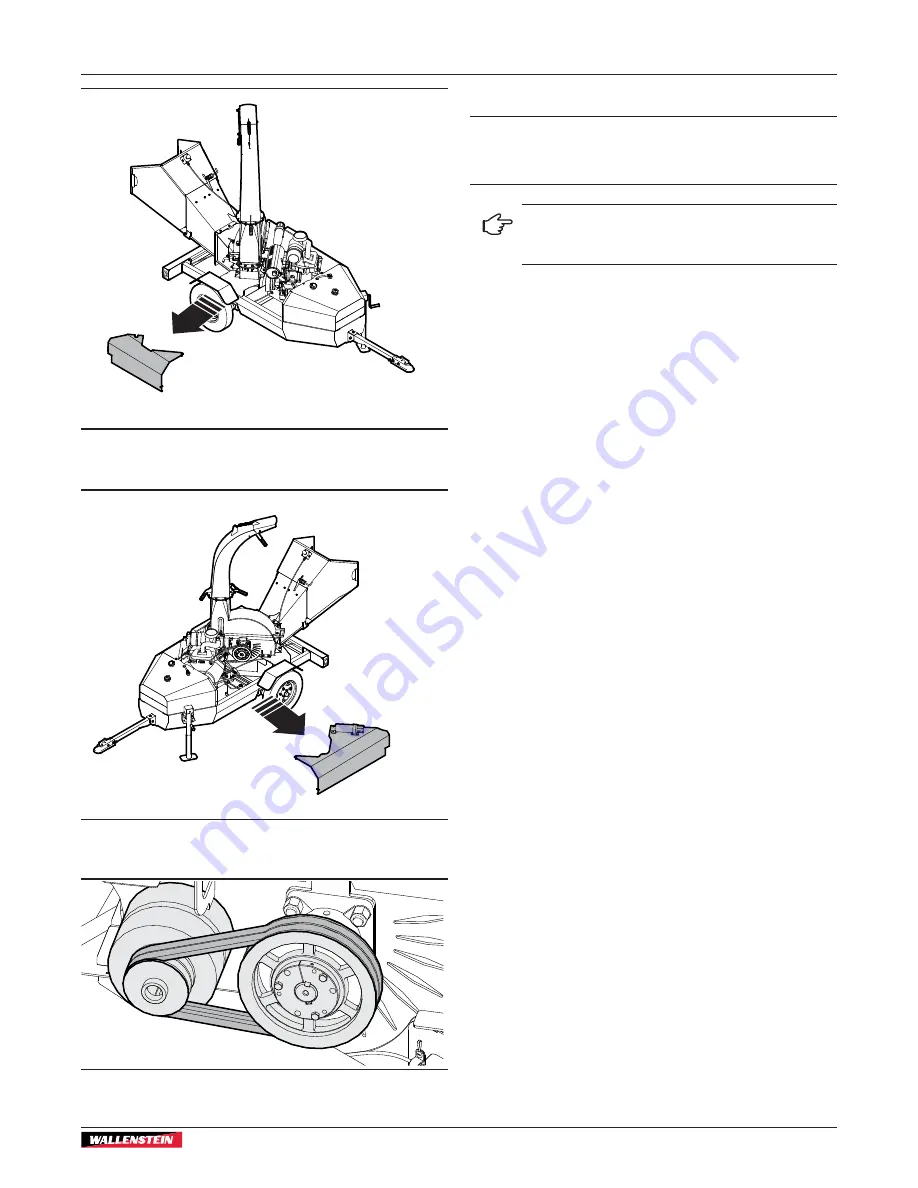

Figure 35 –

Remove the drive-belt guard

02257

Figure 36 –

Drive belt

9.8.2 Set the Drive Belt Tension

IMPORTANT! Adjust the drive belt tensioning bolts evenly.

If the bolts are unevenly adjusted, you may have to align the

engine.

A drive-belt tension gauge, ruler, or tape measure is

necessary for this procedure. A drive-belt tension

gauge is the most accurate tool.

Check the drive belt tension after every 100 hours of

operation.

1.

Press on the top centre of the rotor drive belt and measure

the distance it moves. See

.

2.

Do one of the following:

• If the drive belt movement measures

between

1/4"

(6 mm) and

3/8" (10 mm)

, the drive belt tension is

correct.

You do not need to set the drive belt tension.

• If the drive belt tension is not correct, continue with the

following steps to set the drive belt tension.

3.

Loosen (do not remove) the four bolts that attach the

engine mount to the machine frame. See

4.

Use the drive-belt tensioning bolts to set the drive belt

tension. See

5.

Do steps 1, 2, and 4 again, until the drive belt tension is

correct.

6.

Tighten the four engine mount bolts.

7.

Do step 1 again.

8.

Do one of the following:

• If the belt tension is correct, continue with step 9.

• If the belt tension is not correct, do steps 3 to 7 again.

9.

Align the drive belt.

For instructions, see

Align the Drive Belt on page 58.

10.

Use a calibrated torque wrench to torque the four engine

mount bolts to

19 lbf•ft (25 N•m)

.

11.

Check the drive belt tension again after 10 hours of

operation.

BXT72S

Wood Chipper

Service and Maintenance

57

Summary of Contents for BXT72S

Page 35: ...02220 Figure 20 Set up the machine BXT72S Wood Chipper Operating Instructions 35...

Page 41: ...02225 Figure 26 Transport position BXT72S Wood Chipper Transport 41...

Page 45: ...02227 Figure 30 Storage position BXT72S Wood Chipper Storage 45...

Page 75: ......

Page 76: ...WallensteinEquipment com...