11.3 Lug Nut Torque

WARNING!

Wheel lug nuts must be installed and kept at

the correct torque to prevent loose wheels,

broken studs, or possible separation of a

wheel from the axle.

It is an extremely important safety procedure to apply

and maintain the correct torque on lug nuts that secure

the wheel to the trailer axle. A calibrated torque wrench

is the best tool to make sure that the correct amount of

torque is applied to a fastener.

Tighten wheel lug nuts to the correct torque before

the first use and after each wheel removal. After a

wheel is installed, check and torque the lug nuts after

the first 10 miles (16 km), 25 miles (40 km), and

50 miles (80 km). Check the lug nut torque periodically

thereafter.

•

Start all lug nuts onto the threads by hand.

•

Tighten lug nuts in stages, following the pattern

shown below the Lug Nut Torque Specifications

table.

Lug Nut Torque Specifications

Wheel

size

Units

First stage

Second stage

Third stage

8 inch

lbf•ft

N•m

12–20

16–26

30–35

39–45.5

45–55

58.5–71.5

12 inch

lbf•ft

N•m

20–25

26–32.5

35–40

45.5–52

50–60

65–78

13 inch

lbf•ft

N•m

20–25

26–32.5

35–40

45.5–52

50–60

65–78

14 inch

lbf•ft

N•m

20–25

26–32.5

50–60

65–78

90–120

117–156

15 inch

lbf•ft

N•m

20–25

26–32.5

50–60

65–78

90–120

117–156

16 inch

lbf•ft

N•m

20–25

26–32.5

50–60

65–78

90–120

117–156

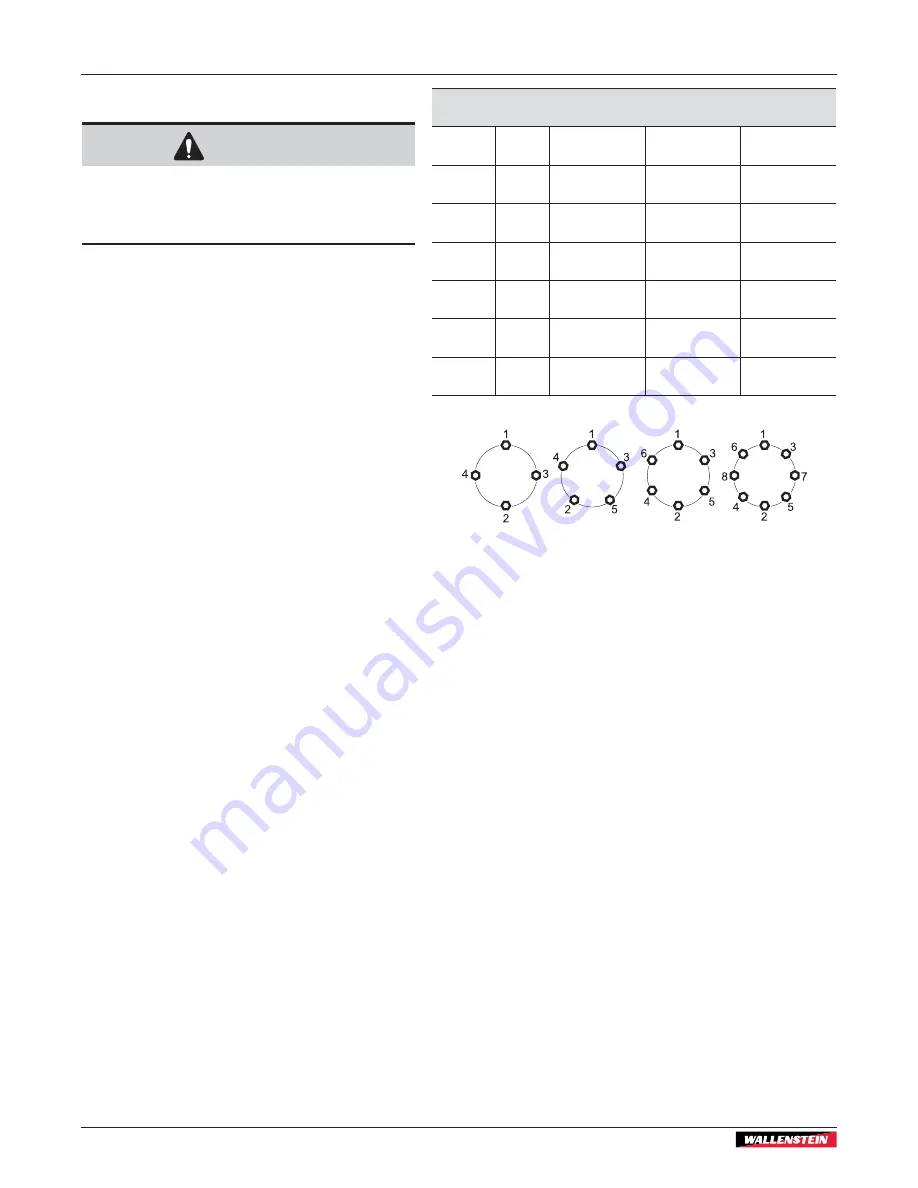

Lug nut torque pattern:

4 bolts

5 bolts

6 bolts

8 bolts

Specifications

BXT72S

Wood Chipper

70

Summary of Contents for BXT72S

Page 35: ...02220 Figure 20 Set up the machine BXT72S Wood Chipper Operating Instructions 35...

Page 41: ...02225 Figure 26 Transport position BXT72S Wood Chipper Transport 41...

Page 45: ...02227 Figure 30 Storage position BXT72S Wood Chipper Storage 45...

Page 75: ......

Page 76: ...WallensteinEquipment com...