Attaching Winch to Tractor

FX66, FX85/R, FX110/R, FX140/R

PTO Skidding Winch

22

00583

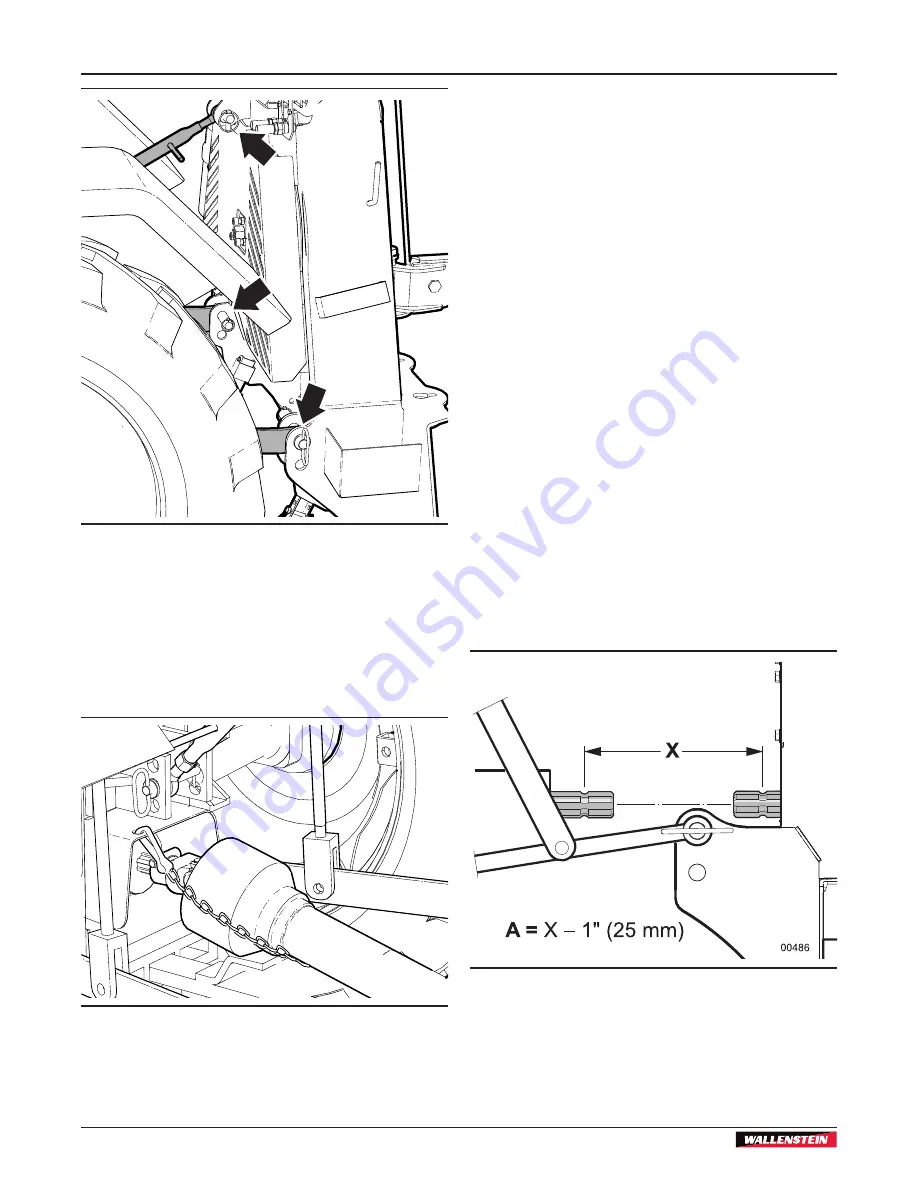

Fig. 8 –

Winch Attached

9.

Slide the collar back on the PTO shaft yoke. Align

the splines and slide the yoke on the tractor PTO.

10.

Release the collar and make sure the locking pin

clicks into position.

11.

Attach the shield anchor safety chain to an

adjacent frame member. The chain keeps the

integral journal shield from spinning.

00584

Fig. 9 –

PTO Shaft Installed

12.

Raise winch support legs to the storage position.

Insert snap lock pins.

13.

Start the tractor and slowly raise the machine

up through its working range to make sure the

telescoping portion of the PTO shaft does not

bottom out.

To detach winch from the tractor, reverse the above

steps.

4.1 Determine Proper PTO Shaft

Length

The PTO shaft that came with your machine may need

to be shortened. A longer shaft is supplied because

tractor lift arms vary in length.

It is very important that the PTO shaft is free to

telescope, and not bottom out when going through its

working range. It should never completely collapse in

use. If the shaft bottoms out, the bearings on both ends

can be overloaded and could fail causing damage or

injury.

1.

Remove the PTO shaft and mount the machine on

the tractor three-point hitch.

2.

Start the tractor and raise the three-point hitch up

off the ground until the machine's input shaft is

level with the tractor PTO output shaft.

3.

Measure the distance between the locking grooves

on the tractor PTO shaft and the attachment input

shaft (X) as shown.

Fig. 10 –

Measurement A

4.

Subtract 1" (25 mm) from this measurement. The

result is the required length of your PTO Shaft.

Call this value

A

.

Summary of Contents for FX110R

Page 49: ......

Page 50: ...www wallensteinequipment com ...