7.7 LXT95 Surge Brakes

IMPORTANT! Repair and maintenance of the brakes should

be performed by a qualified mechanic.

When adjusting or repairing to the brakes, be aware there are a

left- and right-hand brake assemblies.

Trailer brakes must be inspected and serviced immediately if a

loss of performance is indicated. With normal use, servicing at

one-year intervals is usually adequate. With increased usage,

this work should be done more frequently as required.

After replacement of brake shoes and linings, the brakes

must be re-burnished to seat in the new components.

This

should be done by applying the brakes 20 to 30 times from

an initial speed of 40 mph (65 km/h) then slowing to 20 mph

(32 km/h). Allow ample time for brakes to cool between

applications. This procedure allows the brake shoes to seat in to

the drum surface.

Wheel Cylinders

Inspect for leaks and smooth operation. Clean with brake

cleaner and flush with fresh brake fluid. Hone or replace as

necessary.

Brake Lines

Check for cracks, kinks, or blockage. Flush with fresh brake

fluid. Bleed system to remove all air. Replace as necessary.

Shoes and Linings

Replacement is necessary if the lining is worn (less than 1/16"

[1.5 mm]), contaminated with grease or oil, or abnormally

scored or gouged. Hairline heat cracks are normal in bonded

linings and should not be cause for concern.

When replacement is necessary, it is important to replace both

shoes on each brake and both brakes of the same axle. This

helps retain the braking balance. Before reassembling, apply a

light film of grease or anti-seize compound on the brake anchor

pin, the actuating arm bushing and pin, and the areas on the

backing plate that are in contact with the brake shoes.

Hardware

Check all hardware. Check shoe return spring, hold down

springs and adjuster for stretch or wear. Replace as required.

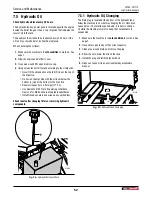

Brake Adjustment

1.

Raise the trailer and secure on adequate jack stands. Make

sure the wheels and drums can rotate freely.

2.

Locate and remove the adjusting hole cover from the slot

on the brake backing plate.

3.

With a screwdriver or standard adjusting tool, rotate the

star wheel of the adjuster assembly to expand the brake

shoes. Adjust the brake shoes out until the pressure of the

linings against the drum makes the wheel very difficult to

turn.

4.

Then rotate the star wheel in the opposite direction until the

wheel turns freely with a slight lining drag.

5.

Replace the adjusting hole cover and lower the wheel to the

ground.

6.

Repeat the above procedure on all brakes. For best results,

the brakes should all be set at the same clearance.

Most of the brake components are very similar to those used in

electric brakes, and maintenance is comparable for the hub and

drum, shoes and linings, and bearings.

LXT95 / LXT115

Log Trailer & Grapple

Service and Maintenance

55

Summary of Contents for LXT115

Page 64: ...www wallensteinequipment com ...