29

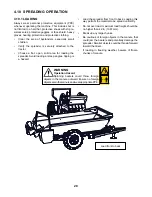

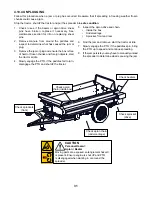

4�10�2 SPREADING - PTO MODELS

Follow this procedure when the spreader is loaded and

ready to go.

1.

With PTO off, move from the loading area to the

field to be spread.

2. Clear the area of bystanders, especially small

children, remain in the drivers seat.

3. Set apron chain speed to Slow, Medium or Fast.

4. Set engine speed to low idle, and slowly engage the

PTO, the beater will start spinning and the apron will

begin to move.

5. Drive ahead to begin unloading the spreader.

6. Increase PTO speed as required, to 540 RPM

maximum.

7. When unloaded, stop the PTO, return to loading

area and repeat loading procedure.

Operational Tips

The best results are obtained when the tractor is driven

into the wind to minimize any material from splattering

on the driver. Reducing ground speed and engine/PTO

speed also reduces the chance of splattering the driver.

The Spreader can be operated between 3 - 6 mph (4.5 -

9 kph) when spreading. Select the ground speed based

on terrain and how fast you want to unload. Generally

the best results are obtained when the ground speed is

slowed as the machine empties to reduce splattering.

Although the Spreader can run a 540 RPM, it is

recommended that it be run at a slower speed. Generally

mid-range gets the job done or 250 - 350 RPM. Operating

at 540 RPM only increases the amount of splatter.

An optional gate is available to go into the frame to

prevent a manure slurry from draining out through the

beaters during loading. Lower the gate before loading

and raise it before starting to unload.

The gate may be required when sand or sawdust is used

as bedding. Neither of these materials have a binding

characteristic and the manure can resemble a slurry. If

it is, it will drain out the back under the beaters while

loading. The gate prevents the slurry from running out.

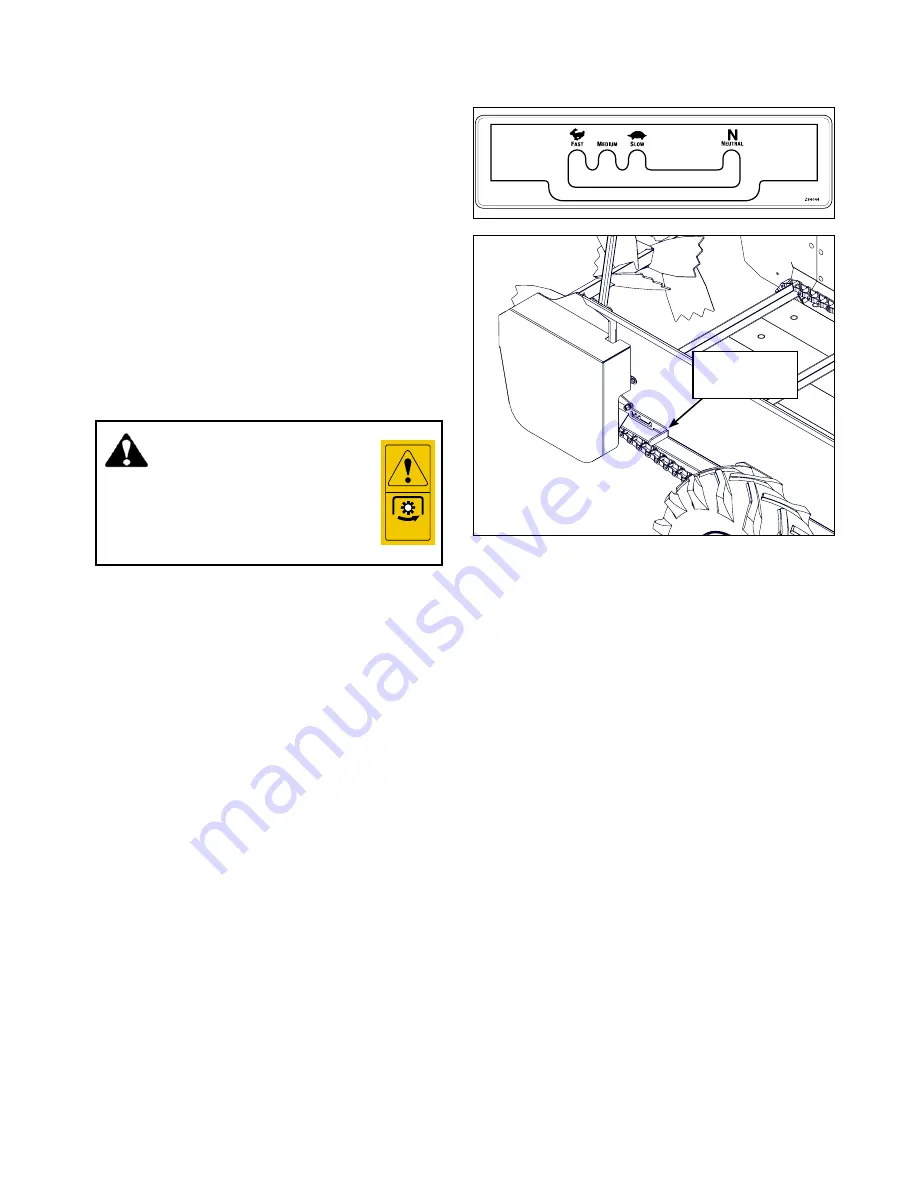

Apron Speed

Lever

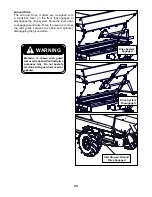

Notice:

Equipment Damage

MX series PTO spreaders are designed to

work at PTO speed of 540 RPM.

Operating

the spreader above 540 RPM will cause

damage to the spreader and will void

the warranty�

Z94246

540 RPM