40

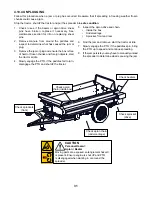

7�5 APRON CHAIN TENSION

An apron chain is used to convey manure into the beaters

for spreading. It must be oiled frequently and kept properly

tensioned to obtain the expected life. To maintain the

apron chain, follow this procedure:

1. Verify the machine is set in

safe condition�

2. Use a pressure washer to clean the spreader.

3. Apply a coat of oil to the chain inside the box.

4. Either run the machine or move it forward to bring

the chain from the bottom side to the top.

5. Apply oil to the chain that has not been coated.

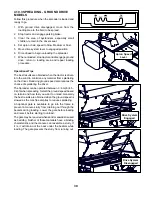

6. Check the chain tension. The chain should sag 6

- 8 in. (150 - 200 mm) below the frame for proper

setting.

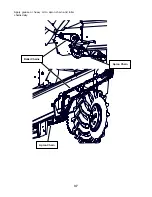

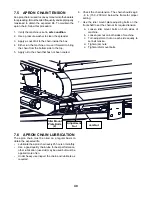

7. Use the idler mount plate adjusting bolts on the

front shaft to set the chain at its required tension.

a. Loosen idler mount bolts on both sides of

machine.

b. Loosen jam nut on both sides of machine.

c. Turn adjustment nut on each side equally to

set belt tension.

d. Tighten jam nuts.

e. Tighten idler mount bolts.

Idler Mount

Plate Bolts

(2)

Adjustment

Nut

Jam Nut

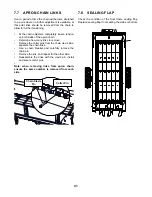

7�6 APRON

CHAIN LUBRICATION

The apron chain must be oiled on a regular basis to

obtain the expected life.

• Lubricate the apron chain every 25 hours or monthly.

• Use a good quality chain lube for best performance,

other lubrication (used oil) may be used but must be

applied more often.

• Under heavy use inspect the chain and lubricate as

required.