Storing the Wood Splitter

WX370

3-point Hitch Wood Splitter

26

6.7.2 Prepare for Transport

•

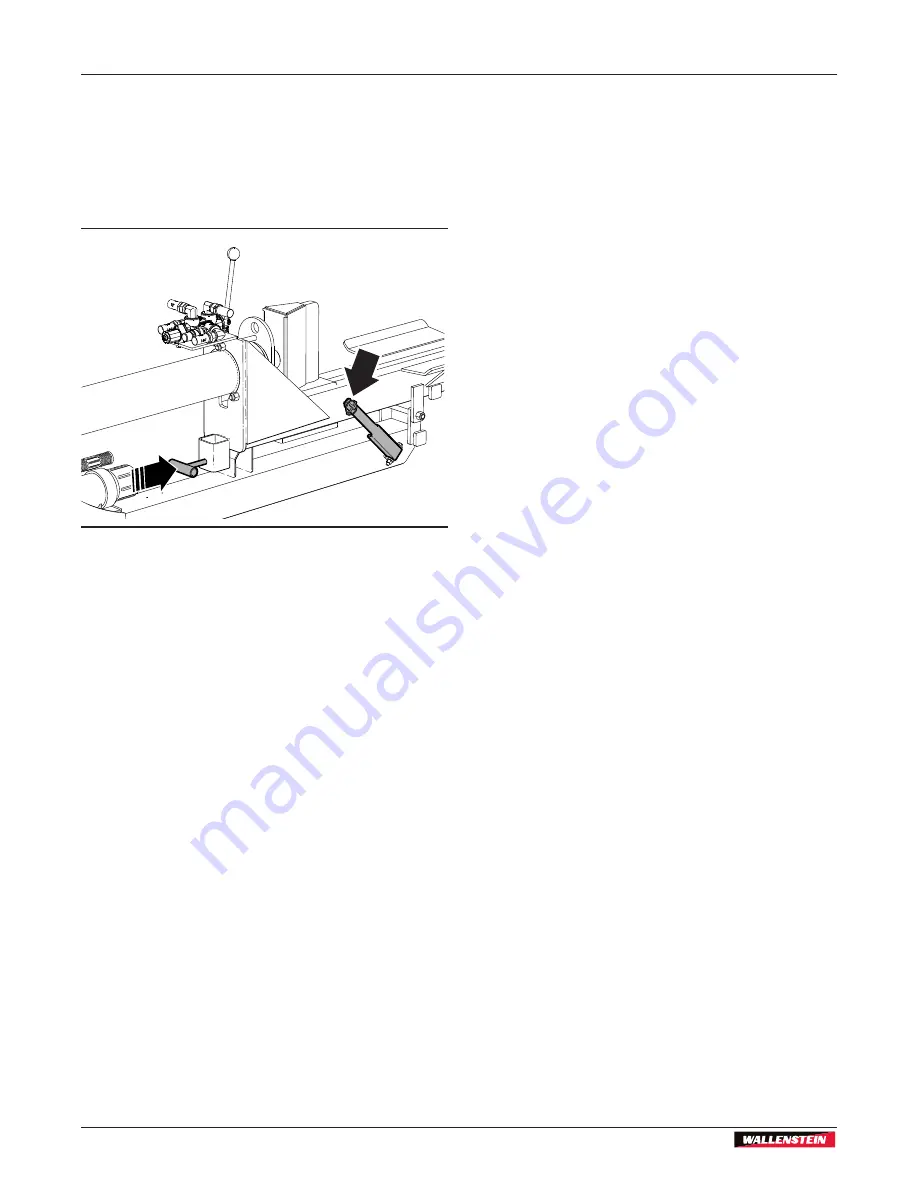

Make sure the pivoting main frame is fully lowered

to horizontal. The lock pin in the pivoting splitter

beam must be fully engaged.

•

Swing the locking latch up to engage the tab on the

splitter frame. Insert the lynch pin.

00750

Fig. 18 –

Lock Pin and Latch Engaged

•

Clean all debris from the splitter that could fall off in

transport.

•

Always be in compliance with all applicable local

regulations when transporting.

7. Storing the Wood Splitter

After the season's use and the wood splitter is going

to be put away in storage, it should be thoroughly

inspected and prepared. Repair or replace any worn

or damaged components to prevent any unnecessary

down time at the start of next season.

The wood splitter can have a long, trouble-free life by

following these steps:

1.

Place the splitter in the horizontal configuration.

Fully retract the cylinder ram.

2.

Thoroughly wash the machine using a pressure

washer to remove all dirt, mud, debris, and

residue.

3.

Inspect the wedge, cylinder ram, anvil and wear

plates for damage or entangled material. Repair

or replace damaged parts. Remove all entangled

material.

4.

Touch up all paint nicks and scratches to prevent

rusting.

5.

Store the machine in an area away from human

activity. Select an area that is dry, level and free

of debris to park the wood splitter. Set it down on

wood blocking.

6.

If the wood splitter is not stored inside a building,

cover with a waterproof tarp. Tie securely in place.

7.

Do not allow children to play on or around the

stored machine.

7.1 Removing from Storage

1.

Review and follow the Pre-operation Checklist.

See

2.

Review safety and operation procedures. See