Service and Maintenance

WX900 Series

Log Splitter

38

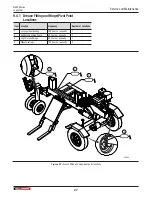

9.5 Hydraulic System Maintenance

The hydraulic system controls the splitting wedge and log lifter

shelf.

9.5.1 Hydraulic System Maintenance

Safety

CAUTION!

Risk of burns to exposed skin.

Hydraulic fluid gets hot during

operation, which makes hoses,

lines, and other parts hot as well.

Wait for the fluid and components to

cool before starting maintenance or

service.

IMPORTANT! Optimal hydraulic fluid temperatures

are between 120° F and 140° F (50° C and 60° C). If the

hydraulic fluid temperature is higher than 180° F (82° C),

it can cause seal damage and degrade the hydraulic fluid.

High hydraulic fluid temperatures often indicate that there is

a problem.

For more information, see

Hydraulic System Operation Safety on

•

Make sure that all hydraulic system components are kept

clean and in working condition.

•

Relieve pressure on the hydraulic system before working

with it. The hydraulic system operates under extremely high

pressure.

•

Before applying pressure to the hydraulic system, make

sure that all the connections are tight, and the hoses and

fittings are not damaged.

•

Replace hydraulic hoses that show signs of swelling,

wear, leaks, or damage. A swollen, worn, damaged, or

leaking hose can burst and cause a hazardous and unsafe

condition.

•

High-pressure hydraulic fluid leaks:

• Do not use your hand to check

for hydraulic fluid leaks. Hydraulic

fluid that leaks under pressure

can penetrate the skin and cause

serious injury or death. Use a piece

of cardboard, wood, or plastic

to check for leaks. Put on heavy

gloves.

• Put on the correct eye protection

when doing an inspection for a

high-pressure hydraulic leak.

• Get medical attention immediately if you are injured by

a concentrated high-pressure stream of hydraulic fluid.

Serious infection or a toxic reaction can occur after

hydraulic fluid pierces the skin.

•

Do not make any temporary repairs to the hydraulic hoses

or fittings. Do not use tape, clamps, or cements to attempt

a repair. This can cause sudden failure and create a

hazardous and unsafe condition.

•

Do not bend or strike high-pressure hoses or reinstall them

in a bent or damaged condition.

•

Make sure that hydraulic hoses are routed to avoid chafing.

•

Never adjust a pressure relief valve or other pressure-

limiting device to a pressure that is higher than the

specified rating.

Summary of Contents for WX900 Series

Page 48: ...WallensteinEquipment com...