Operating Instructions

WX900 Series

Log Splitter

24

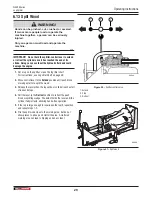

6.5.5 Add Fuel to the Engine

Fuel tank capacity:

0.82 US gal (3.1 L).

WARNING!

Never smoke or vape while working

with fuel. Fuel vapors can explode

causing injury or death. Keep sparks,

fl ames, and hot components away.

W027

Refuel in a well-ventilated area with the engine stopped. If the

engine has been running, allow it to cool first. Never refuel the

engine inside a building where gasoline fumes can come in

contact with flames or sparks.

For fuel specification, see

Fluids and Lubricants on page 33

Refer to the engine manual for additional information on fuels.

1.

Clean the area around fuel tank cap.

Fill the tank to 1/2”

(12 mm) below bottom of filler neck to provide space for

any fuel expansion.

Do not overfill.

2.

Install fuel fill cap securely and wipe up any spilled fuel.

6.6 Hydraulic System Operation

IMPORTANT! Check the hydraulic fluid quality every

50 hours. If the fluid is dirty or smells burnt, replace it.

IMPORTANT! Be aware of high fluid temperatures.

Temperatures higher than 180 °F (82 °C) can cause damage

to the seals and degrade the hydraulic fluid quality.

The hydraulic system is a closed-loop system that uses

pressurized automatic transmission fluid (ATF) to control the

splitter-control and log lifter shelf control valves.

6.6.1 Hydraulic System Operation Safety

IMPORTANT! Optimal hydraulic fluid temperatures

are between 120° F and 140° F (50° C and 60° C). If the

hydraulic fluid temperature is higher than 180° F (82° C),

it can cause seal damage and degrade the hydraulic fluid.

High hydraulic fluid temperatures often indicate that there is

a problem.

For more information, see

Hydraulic System Maintenance Safety

•

Make sure that all hydraulic system components are kept

clean and in working condition.

•

Replace a hydraulic hose that shows signs of swelling,

wear, leaks, or damage immediately. A swollen, worn,

damaged, or leaking hose can burst and cause a hazardous

and unsafe condition.

•

High-pressure hydraulic fluid leaks:

• Do not use your hand to check

for hydraulic fluid leaks. Hydraulic

fluid that leaks under pressure

can penetrate the skin and cause

serious injury or death. Use a piece

of cardboard, wood, or plastic

to check for leaks. Put on heavy

gloves.

• Put on the correct eye protection

when doing an inspection for a

high-pressure hydraulic leak.

• Get medical attention immediately if injured by a

concentrated high-pressure stream of hydraulic fluid.

Serious infection or a toxic reaction can occur after

hydraulic fluid pierces the skin.

•

Do not bend or hit high-pressure hydraulic hoses.

•

Never adjust a pressure relief valve or other pressure-

limiting device to a pressure that is greater than the

specified rating.

Summary of Contents for WX900 Series

Page 48: ...WallensteinEquipment com...