WX900 Series

Log Splitter

Operating Instructions

25

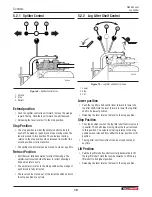

6.6.2 Check the Hydraulic Fluid Level

IMPORTANT! Do not operate machine if fluid level is not

visible on the dipstick. Damage to the pump and other

components can occur.

Do not overfill the tank past the full mark.

Always check fluid levels after changing filters or servicing

hydraulic components.

Hydraulic fluid quality should be inspected every 40 hours. If

the fluid is dirty or smells burnt, it should be replaced.

Be aware of high hydraulic fluid temperatures.

Temperatures higher than 180 °F (82 °C) could cause seal

damage and degrade the fluid quality.

hydraulic fluid level every 40 hours or weekly.

Check with the machine parked on level ground and the engine

stopped.

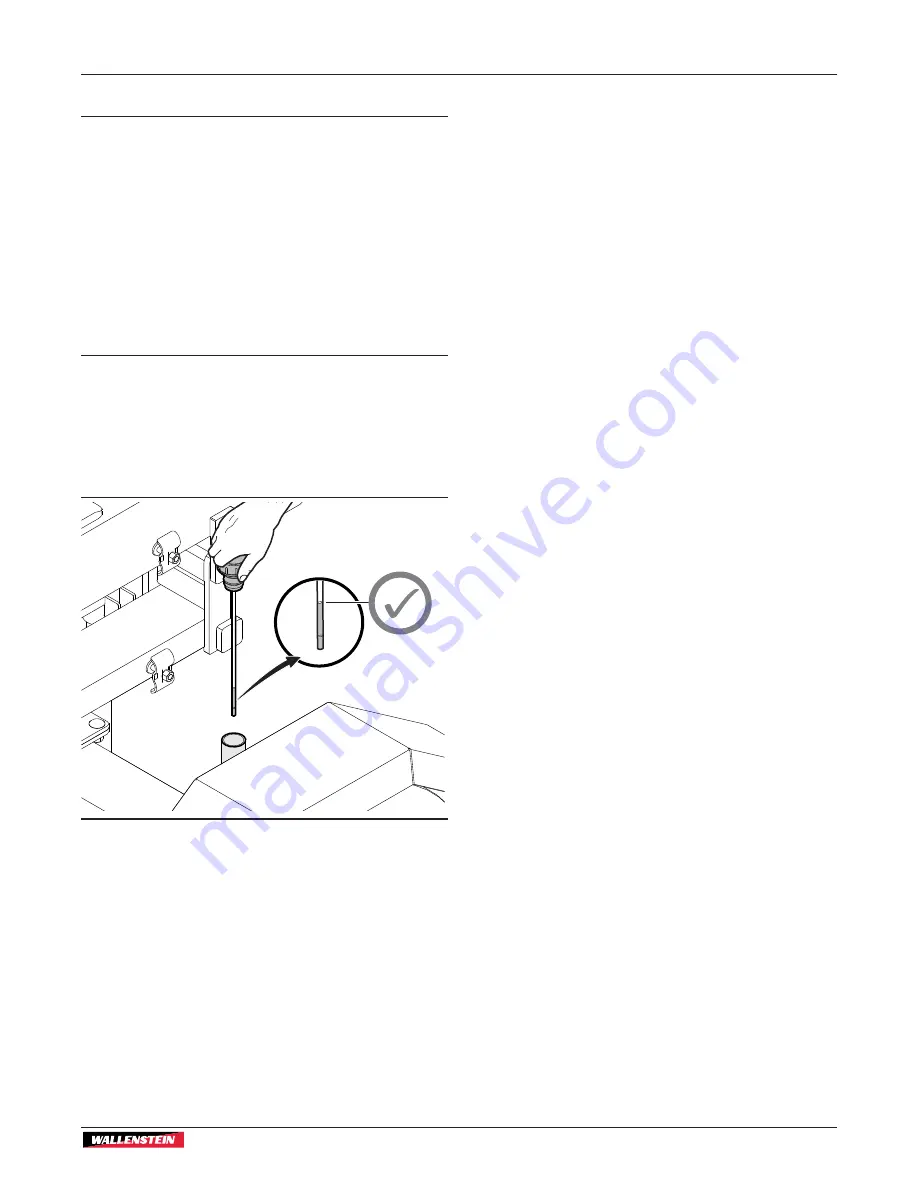

The proper level is when the fluid is visible at the full (upper)

mark on the dipstick.

02219

Figure 14 –

Hydraulic tank fluid level dipstick

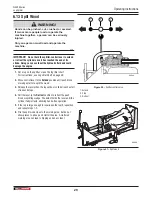

6.6.3 Add Hydraulic Fluid

The hydraulic system uses

Dexron® III ATF

. Dexron VI or

Mercon

®

are acceptable substitutes.

1.

Check the hydraulic fluid level to make sure that the fluid

level is low.

For instructions, see

Check the Hydraulic Fluid Level.

2.

Set the machine to a safe condition.

For instructions, see

3.

Clean the area around the fill cap.

4.

Remove the fill cap.

5.

Use a clean funnel to add hydraulic fluid to the reservoir

until the fluid fills the bottom half of the sight glass.

Do not overfill the reservoir.

6.

Remove the funnel.

7.

Install the fill cap and make sure that it is tight.

8.

Clean the area around the fill cap and remove any spilled

fluid.

Summary of Contents for WX900 Series

Page 48: ...WallensteinEquipment com...