WX900 Series

Log Splitter

Operating Instructions

27

6.8 Start the Machine

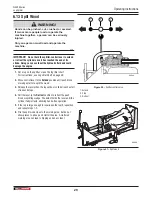

WARNING!

Fast retraction of the starter cord (called

kickback) pulls your hand and arm toward the

engine faster than you can let go of the handle.

Serious bodily harm (for example; bruises,

sprains, fractures, and broken bones) can result.

When starting the engine, pull the starter cord

slowly until you feel resistance, and then pull it

rapidly to avoid kickback.

W102

WARNING!

Before you start the machine, read and

understand all of the safety information in this

manual, the engine manufacturer's manual, and

the chain saw manufacture's manual.

IMPORTANT! If the engine does not start after

repeated attempts, contact your local dealer or go to

Before you start the machine, see the information under

1.

Complete the tasks described in the

2.

Make sure that the machine is set up correctly, level, and in

a stable position.

3.

Move the hydraulic controls to the neutral position (out of

detent).

4.

Move the choke control to the

Closed

position.

5.

Move the throttle control to the

Fast

position.

6.

Firmly grip the starter-cord handle.

7.

Pull the starter cord out slowly until you feel resistance, and

then pull it rapidly.

8.

When the engine warms up, move the choke control to the

Open

position.

6.9 Stop the Machine

IMPORTANT! Do not choke the carburetor to stop the

engine.

1.

Stop loading material onto the splitter bed.

2.

Move the hydraulic controls to neutral.

3.

Move the engine throttle control to the

STOP

position to

turn off the engine and close the fuel shutoff valve.

4.

Activate each hydraulic control two or three times to relieve

the hydraulic system pressure.

6.10 Emergency Stop

In an emergency:

1.

Move the hydraulic controls to neutral.

2.

Move the engine throttle control to the

STOP

position to

turn off the engine and close the fuel shutoff valve.

3.

Activate each hydraulic control two or three times to relieve

the hydraulic system pressure.

4.

Remove the cause of the emergency before starting the

engine and resuming work.

Summary of Contents for WX900 Series

Page 48: ...WallensteinEquipment com...