WX900 Series

Log Splitter

Service and Maintenance

33

9. Service and Maintenance

WARNING!

Risk of serious personal injury. Stop engine

before performing ANY service or maintenance

procedure. Reinstall all covers and shields

removed before putting machine back into

service.

W033

IMPORTANT! Refer to the engine manufacturer's manual

for engine maintenance and service information.

9.1

Maintenance Safety

•

Follow good shop practices:

-

Keep service area clean and

dry.

-

Be sure electrical outlets and

tools are properly grounded.

-

Use adequate light for the job

at hand.

•

Never operate the machine or the towing vehicle in a closed

building. The exhaust fumes may cause asphyxiation.

•

Before servicing or repairing, place the machine in a

Safe

Condition

•

Allow the engine to cool before performing maintenance.

Engine components and oil may be hot enough to cause

injury.

•

Never work under equipment unless it is properly

supported.

•

When performing any service or maintenance work always

use personal protective equipment.

•

Where replacement parts are necessary, use only OEM

parts to restore your equipment to original specifications.

The manufacturer is not responsible for injuries or damages

caused by use of unapproved parts or accessories.

•

Inspect and tighten all bolts, nuts and screws. Check that

all electrical and fuel connections are properly secured.

•

When completing a maintenance or service function, make

sure all safety shields and devices are installed before

placing splitter in service.

•

When cleaning any parts, do not use gasoline. Use a

cleanser designed for that purpose.

•

Always use proper tools in good condition. Make sure

you understand how to use them, before performing any

service work.

9.2

Fluids and Lubricants

The machine requires various fluids and lubricants for operation

and maintenance.

9.2.1 Lubricant Handling and Storage

For optimum machine efficiency, use clean lubricants and clean

containers to handle all lubricants. Store lubricants in an area

that is protected from dust, moisture, and other contaminants.

9.2.2 Engine Oil

For engine maintenance and service information, see the

engine manufacturer's manual.

Briggs & Stratton® Warranty Certified oils are recommended

for the best engine performance. However, other high-quality

detergent oils are permitted if they are classified for service SF,

SG, SH, SJ, or higher. Do not use special additives.

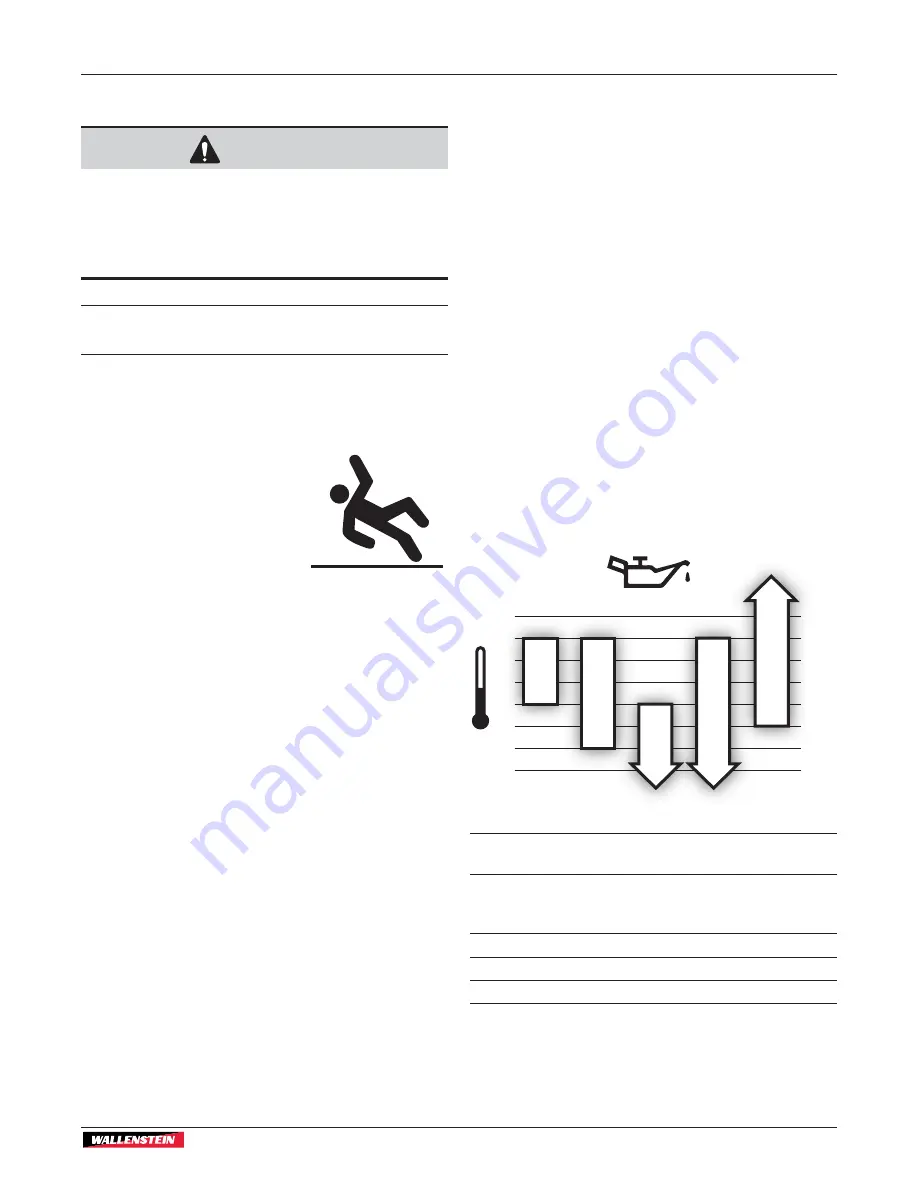

Outdoor temperatures determine the required engine oil

viscosity. Select the best oil viscosity for the expected outdoor

temperature range. Use the following chart as a guide:

°F

20

-7

°C

120

49

100

38

80

27

60

15

40

4

0

-18

-20

-29

A

B

C

D

E

01802

A

SAE 30

– Below 40 °F (4 °C) the use of SAE 30 results

in hard starting.

B

10W-30

– Above 80 °F (27 °C) the use of 10W-30

may cause increased oil consumption. Check the oil

level frequently.

C

5W-30

D

Synthetic 5W-30

E

Vanguard® Synthetic 15W-50

Summary of Contents for WX900 Series

Page 48: ...WallensteinEquipment com...