25/88

WALLMEK

i Kungälv AB - Special tools for auto repairs

www.wallmek.se • info@wallmek.se • Tel. +46(0)303 58580 • Bultgatan 18, 442 20 Kungälv, Sweden

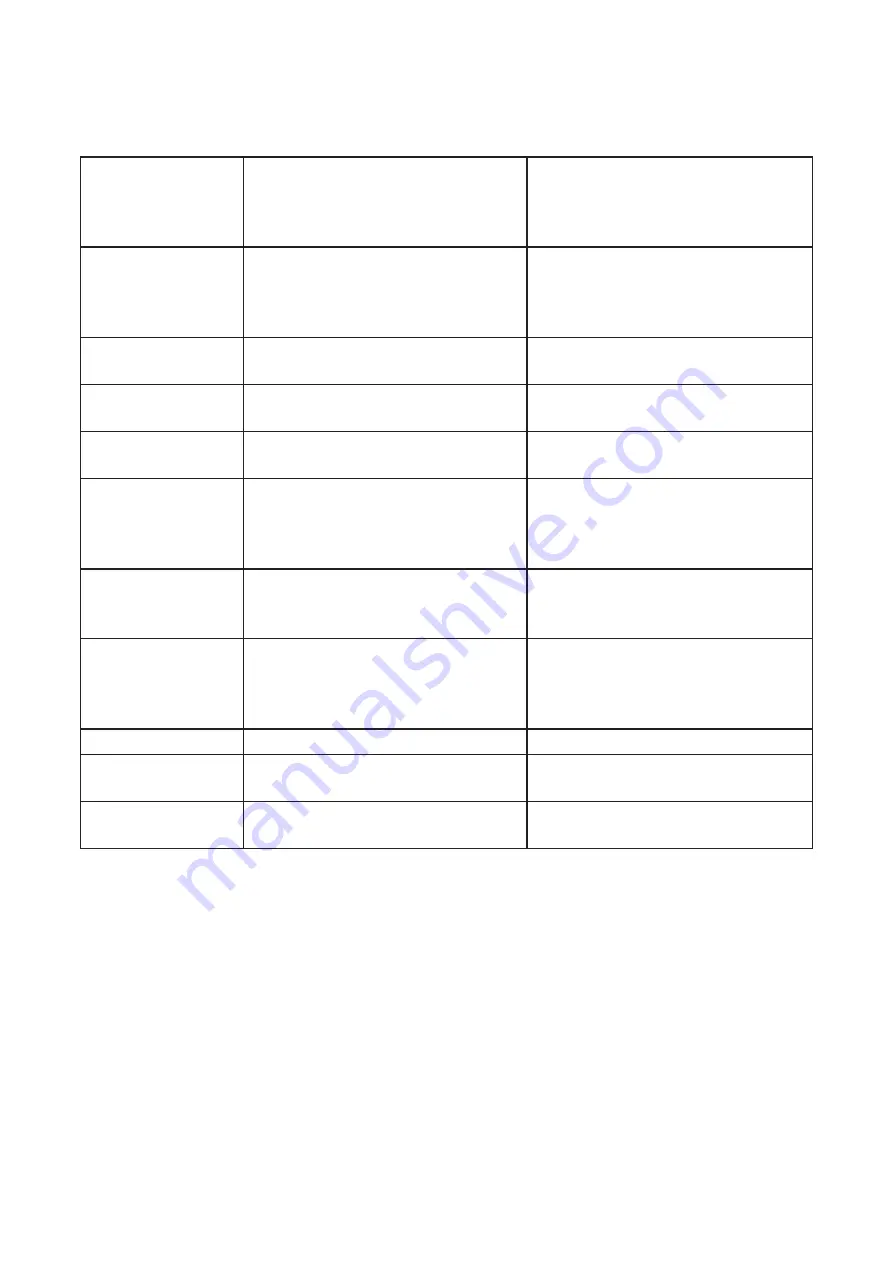

The stand tips over

when pressing

Incorrect stand position

Position the stand with one leg

positioned straight under the spring

strut (is right when the stand is rolled

in on the wheels)

Spring still

tensioned when the

spring compressor is

lowered

Disc above the spring rusted away

Raise the car on the lift until the

tension releases. Always start

pressing with the plunger extended

10 cm

Compression of

loose spring strut:

Claws in the outer

holes

Move the claws to the inner holes

Spring compressed

unevenly

Pretension required

Adjust grip with pretension

The shock absorber

is off centre in

the spring during

compression

Pretension required

Adjust grip with pretension

Poor alignment

between the spring

and claw

Wrong size claw

Change to the right claw

Spring strut loosens The operator pulls the spring strut

when loaded

Arms not locked with the adjuster

screws

Never pull the spring strut when

loaded

Lock the arms with the adjuster

screws

Hydraulic support:

The car lifts

Too much force being used

Reduce the force. The support must

not be used as a lift.

Top section slides on

the car

Car positioned incorrectly

Adjust so it cannot slide

In the event of further operating disruptions contact service.

Venting the hydraulic system:

Air can accidentally enter the hydraulic system. To vent the system, follow the instructions below:

1.

Let the cylinder unit stand upright in the stand base.

2.

Pump out the plunger as far as possible.

3.

Return the plunger fully.