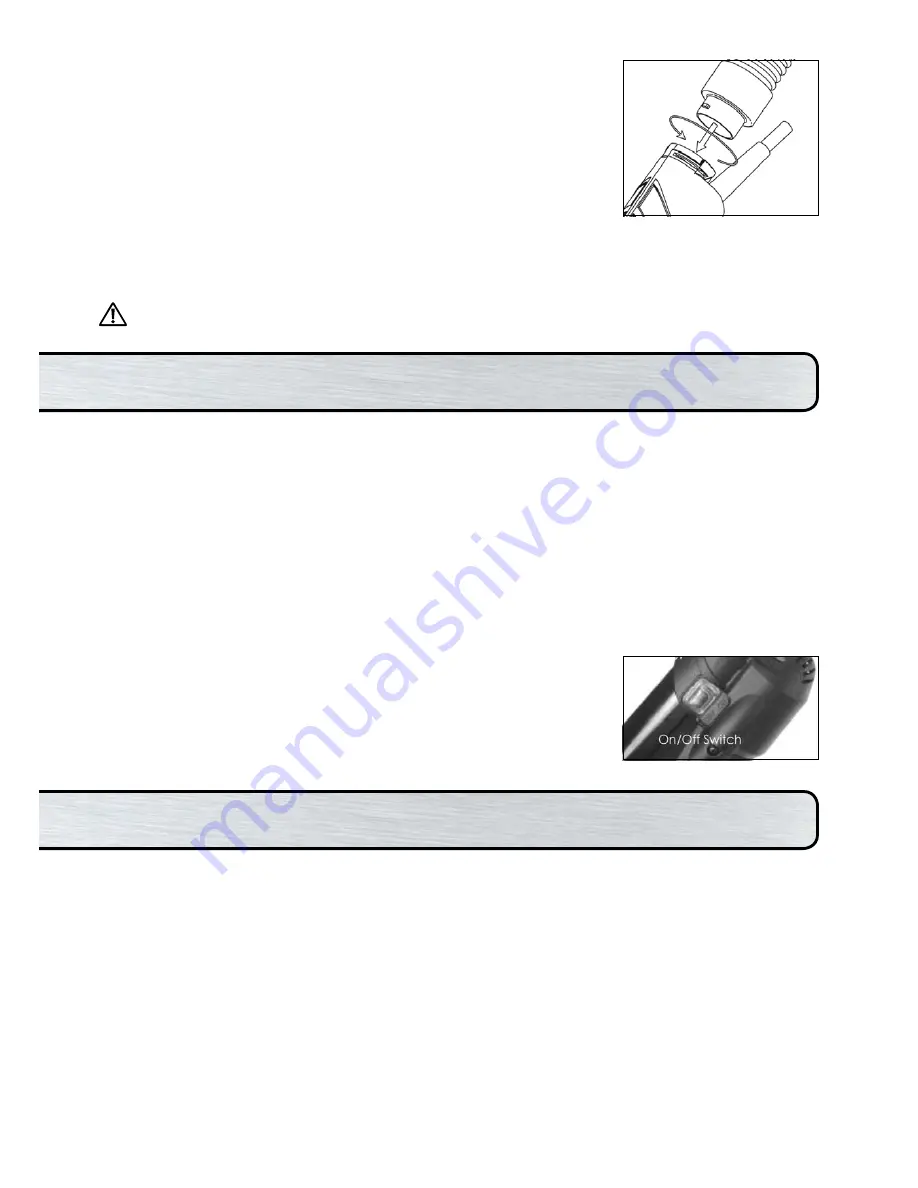

To install the vacuum cleaner hose:

1. Unplug the machine.

2. Plug the vacuum cleaner hose bayonet mount into the swivel mount

in the back of the machine. Once the tangs of the bayonet mount are

fully inserted in the slots, hold the swivel mount from turning and turn

the hose bayonet mount clockwise to lock.

3. Removal is the opposite of assembly.

The vacuum cleaner:

Ensure that you have a bag installed in your vacuum cleaner which is approved and rated for

plasterboard dust.

WARNING:

Failure to use an approved dust bag in your vacuum will increase the level of

airborne dust in the work area. Prolonged exposure to such dust may cause respiratory harm.

Make sure that the power circuit voltage is the same as that shown on the specification plate of the

machine and that switch is “OFF” before connecting the tool to the power circuit.

Switching the machine on and off

To switch on:

While holding with the left hand on the column and the right hand on the main handle,

Press the rocker switch to the right with the thumb of the right hand. Anticipate and be ready for the

start up torque when the machine first starts.

To switch off:

Press the rocker switch to the left. After the machine has been switched off, the

sanding disc will still rotate for a time. Take care that parts of your body do not come into contact with

the disc and do not set the machine down while it is still rotating!

Adjusting the rotation speed:

The speed of the machine is variable to suit different tasks. It can be

adjusted from 650/min up to 1600/min by using the thumb wheel. Using

the right thumb, turn in the downward (counterclockwise) direction to

increase the speed and in the upward (clockwise) direction to decrease

the speed. Generally, you should use the higher speed for fast stock

removal and the lower speed for more precise control.

Effective control of this powerful sander requires

two-handed

operation for maximum safety and

control.

The proper hold is to keep one hand on the main handle and the other hand on the sponge grip on the

column. It is vitally important to keep stable footing at all times, especially when standing on scaffolding

or stilts.

Starting and Stopping Tool

How to use the tool

Summary of Contents for PS-1000

Page 1: ...OPERATING INSTRUCTIONS POWER SANDER model PS 1000...

Page 10: ...PS 1000 Exploded View...

Page 13: ......

Page 14: ...CUSTOMER SERVICE 1300 653 177...