16

Ø

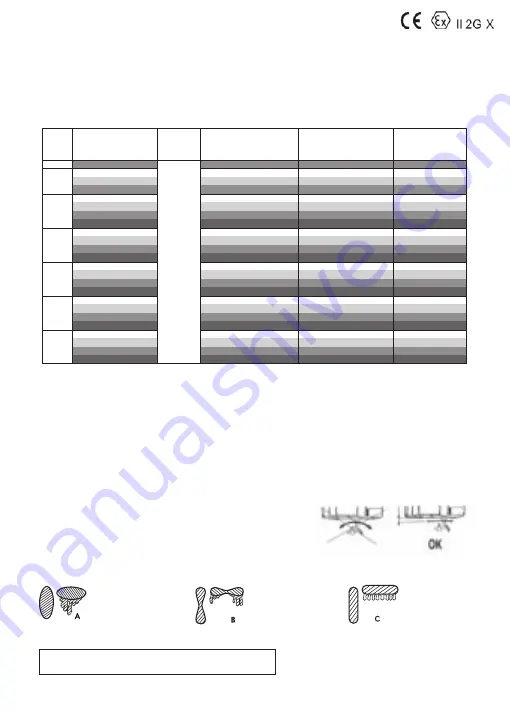

Feed

**Product load

Air consumption

Fan dimensions

at 20 cm (7.9”)

Delivery

pressure

1.0

1.3

1.5

1.7

1.9

2.2

2.5

SP version

220-240 Lt./min (7.8-8.5 CFM)

220-240 Lt./min (7.8-8.5 CFM)

220-240 Lt./min (7.8-8.5 CFM)

220-240 Lt./min (7.8-8.5 CFM)

220-240 Lt./min (7.8-8.5 CFM)

220-240 Lt./min (7.8-8.5 CFM)

220-240 Lt./min (7.8-8.5 CFM)

220-240 Lt./min (7.8-8.5 CFM)

220-240 Lt./min (7.8-8.5 CFM)

220-240 Lt./min (7.8-8.5 CFM)

220-240 Lt./min (7.8-8.5 CFM)

220-240 Lt./min (7.8-8.5 CFM)

220-240 Lt./min (7.8-8.5 CFM)

180-220 Lt./min (6.4-7.8 CFM)

180-220 Lt./min (6.4-7.8 CFM)

180-220 Lt./min (6.4-7.8 CFM)

180-220 Lt./min (6.4-7.8 CFM)

180-220 Lt./min (6.4-7.8 CFM)

180-220 Lt./min (6.4-7.8 CFM)

Gravity

324 Gr/min.(11.4 oz/min.)

228 Gr/min.(8 oz/min.)

20 cm (7.9”)

18 cm (7.1”)

18 cm (7.1”)

20 cm (7.9”)

20 cm (7.9”)

22 cm (8.7”)

22 cm (8.7”)

22 cm (8.7”)

24 cm (9.5”)

26 cm (10.2”)

26 cm (10.2”)

26 cm (10.2”)

242 Gr/min.(8.5 oz/min.)

260 Gr/min.(9.2 oz/min.)

280 Gr/min.(9.9 oz/min.)

294 Gr/min.(10.4 oz/min.)

328 Gr/min.(11.6 oz/min.)

348 Gr/min.(12.3 oz/min.)

410 Gr/min.(14.5 oz/min.)

432 Gr/min.(15.3 oz/min.)

502 Gr/min.(17.7 oz/min.)

588 Gr/min.(20.8 oz/min.)

SP version

Gravity

Gravity

Gravity

Gravity

Gravity

Suction

Suction

Suction

Suction

Suction

Suction

SP version

SP version

SP version

HD

SP version

SP version

2.5-3.0 bar

(36-43 psi)

MOD.

................................................................................................

9011 / 9010 / 9010 sp HTE

...

TECHNICAL SPECIFICATIONS

...

USE

...

ADVICE FOR CORRECT USE

...

FORM OF THE FAN

...

ADJUSTMENTS

- Air fitting: G 1/4” M

- Product delivery fitting (version SP): G 1/4” M

- Maximum air pressure: 5 bar (73 psi)

- Maximum product pressure (SP version): 5 bar (73 psi)

- Working pressure: 2.5-3.0 bar (36-43 psi)

- Fan: Fully open

- Air: Fully open

- Product: 3-3.5 turns

** Product flow was calculated with water, setting the recommended regulations.

Spray guns int the 9000 HTE series have been designed for the application of finishing colours in all those sectors requiring

high quality finishing and low fumes emission.

The instrument is not suitable for use with abrasives or products containing acids or petrol of any kind.

To obtain the best results, the following instructions must be followed carefully:

1

. When possible, use an air pipe with a minimum internal section of ø 8 mm (0.3”).

2.

Make sure the compressed air used is perfectly filtered removing all water, oil or other impurities (for example, by installing

an Asturomec filter regulator ref. 61131 and Asturomec coalescent microfilter ref. 61201, or by the more complete and efficient

WALCOM TD

3

PRO multifunctional filter and heating unit).

1. The distance between the spray gun and the surface to be painted must be set between 150 and 200 mm (5.9”- 7.9”).

If the spray gun is working at too low a pressure and at too high a distance, il will not perform to the best of its capacity.

2.

The jet from the spray gun must always be perpendicular to the surface being

painted and the paint must be applied in horizontal strokes. Any eventual shift from

this position when spraying will result in an uneven application of the paint layer.

3.

Correct viscosity of the paint is between 15 and 25 sec. Coppa Ford n. 4. These

values depend on the application in question and the measure of the nozzle in use.

Adjust the air pressure, product quantity and spray aperture

until obtaining a regular imprint as in fig. C

- Air pressure too low

- Product viscosity too high

- Quantity of product too high

- Air pressure too high

- Product viscosity too low

- Quantity of product too low

- Regular jet

Summary of Contents for Asturomec 6010 sp HVLP

Page 66: ...Note ...

Page 67: ...Note ...