14

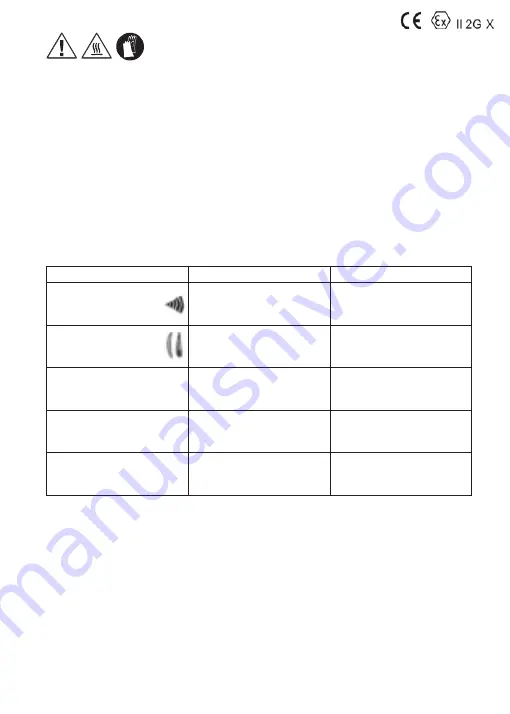

SPECIAL CONDITIONS FOR SAFE SPRAY GUN USE:

. . .

FAILURES AND REMOVAL OF THEIR CAUSES

When using the spray gun, heat hazards may be due to:

- the use of hot compressed air;

- heated primer and finish product application.

In these situations, at most, the spray gun surface reaches the compressed air or primer and finish product temperatures.

In these conditions, pay ATTENTION to the following:

- the spray gun surface temperature should not exceed the burning limit of 43°C (UNI EN 1953 paragraph 5.4).

If this is the case, hand protection must be worn: (for example, heat resistant antistatic gloves);

- the spray gun surface temperature should never exceed 85°C, temperature sufficiently lower than the minimum

ignition temperature (

TMA

) of solvents commonly used for bodywork, woodwork and industrial painting;

- in case of doubt, ask your dealer for information on the solvent

TMA

.

The list of construction materials used will be provided upon request..

FAULT

CAUSE

SOLUTION

INTERMITTENT JET

UNEVEN JET

AIR BUBBLES IN THE

PAINT TANK

PRODUCT LEAKS FROM

NOZZLE

DURING 1ST PHASE

AIR LEAKS WITHOUT

PULLING THE LEVER

- Stuffing box needle loose

- Stuffing box needle worn

- Nozzle not fully tightened

- Nozzle cone ruined

- Tighten the needle stuffing box nut

- Replace the stuffing box needle

- Tighten nozzle

- Replace nozzle

- Air cap holes are dirty or damaged

- Central hole on cap is damaged

or dirty

- Nozzle is dirty or damaged

- Clean carefully nozzle and cap

(with cleaning kit Ref. 90109/W)

if problem persists replace them.

- Paint nozzle is loose

- Nozzle is worn out

- Firmly tighten the nozzle

- Replace nozzle

- Nozzle and needle are clogged with

dry paint

- Nozzle or needle is damaged

- Needle pusher spring missing

- Clean carefully needle and nozzle

- Replace needle and nozzle

- Insert the needle spring

- Rear air stuffing box worn

- Shutter worn

- Valve scratched

- OR valve worn

- Replace rear air stuffing box

- Replace shutter

- Replace valve

- Replace OR valve

Summary of Contents for Asturomec 9011 sp HVLP

Page 53: ...53 1 2 ATEX 0 85 A Asturomec 90109 W...

Page 54: ...54 43 C UNI EN 1953 5 4 85 C TMA TMA 90109 W...

Page 66: ...Note...

Page 67: ...Note...