14

TD

3

PRO TECHNICAL SPECIFICATIONS

Power:

220-240 Vac 50-60 Hz vers. 230 V - 100-130 Vac 50-60 Hz vers.115 V

Maximum power:

3000 W

Insulation:

grounded metallic parts

Power adjustment system:

TRIAC driven by electronic controller with built-in PID algorithm based on the thermocou-

ple in the heater

Maximum temperature control system on the resistances:

TRIAC driven by thermocouple near the resistances;

safety thermostat

Electrical protections:

16A fuse, 500 mA, 6.3A for vers 230 V - 1A and 8A for vers 115 V

Regeneration duration:

Max 4 h.

Admitted temperature field:

from 19° to 70°C - from 66°F to 158°F

Maximum input pressure:

8 bar/116 PSI

Maximum flow:

>1200 l/min @ 6 bar - > 42,37 cfm@87 PSI

Air purification:

- first condensation separator stage with 25 micron mesh filter; automatic “heavy duty” condensation drain;

- second coalescent de-greaser stage with 0,01 micron mesh filter; 99,99999% solid particle retention

efficiency; <0.01 mg/m

3

maximum oil residue; manual oily condensate drain;

- absorption dryer third stage with silica gel: <1.2% residual humidity; < -30°C dp - < -22°F dp output air dew point

temperature.

- active carbon fourth stage for gaseous pollutant removal such as oily fumes, hydrocarbons and odours;

<0.003 mg/m

3

maximum oil residue; generates breathable air.

Working pressure regulation:

membrane pressure regulator with pressure gauge downstream from filtering elements.

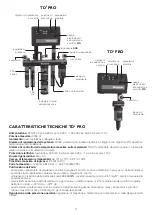

control and

setting display

on/off

switch

fault

signaller

PID

electronic

control panel

pressure

gauge

pressure

gauge

silica filter saturation

level indicators

water

filter

oil

filter

breathable air outlet

heater

element

active carbon filter

pressure

regulator

solenoid valve

SRS

TD

3

PRO

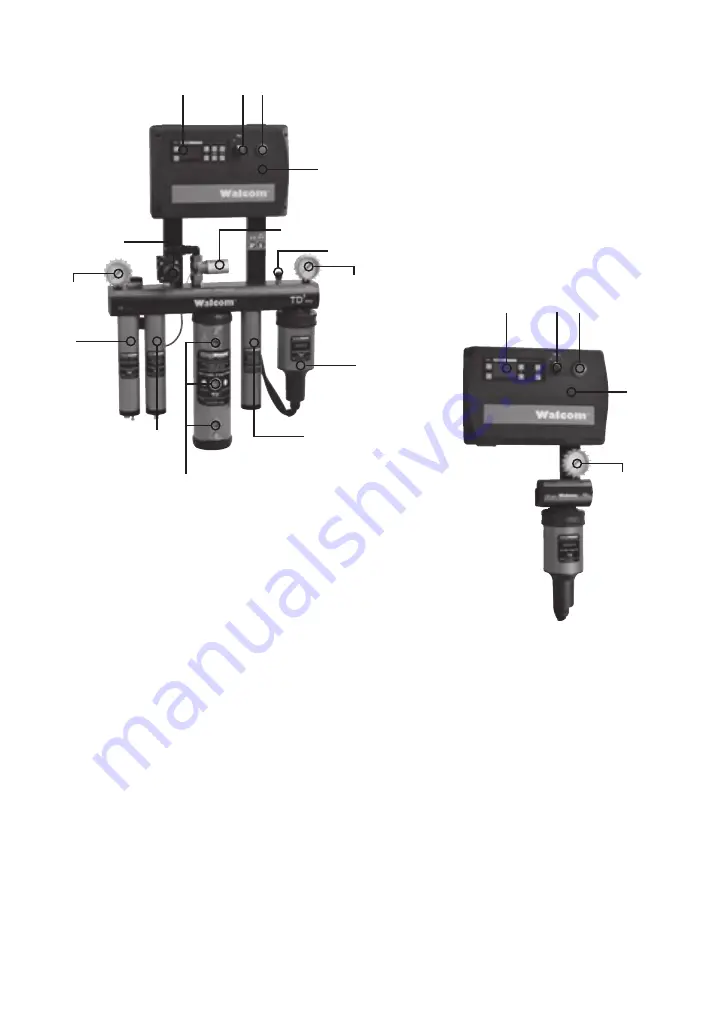

control and

setting display

on/off

switch

fault

signaller

PID

electronic

control panel

pressure

gauge

heater

element

TD

1

PRO

Summary of Contents for TD1 PRO

Page 66: ...66 Note ...