15

EN

NOTES

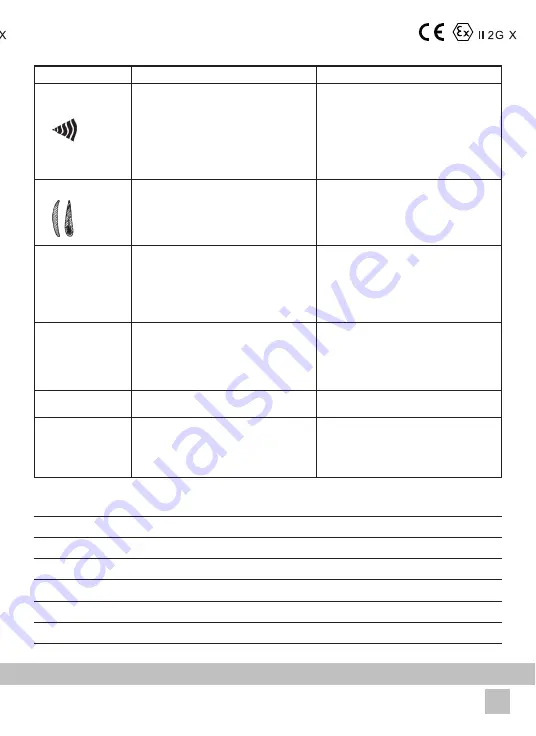

FAILURES AND REMOVAL OF THEIR CAUSES

FAULT

CAUSE

SOLUTION

Intermittent fan spray

Air bubbles

in the cup

Uneven fan spray

Product leaks from

the nozzle during

“1st phase” operations

Air leaks without

pulling back

the lever

Air leaks when

lever is pulled back

1 - Nozzle and sealing cone to the body are not clean;

2 - Nozzle has not been tightened enough;

3 - Ring nut and cap not properly tightened to the body;

4 - Worn out or damaged nozzle sealing cone;

5 - Deflector (S.Xlight-S.Kombat models) damaged and/

or missing;

6 - Loose stuffing box needle;

7 - Worn out or damaged stuffing box needle;

8 - Cup or cup coupling not tight enough.

1 - Nozzle and needle are not clean;

2 - Needle pusher spring missing and/or needle-adjusting

handwheel missing;

3 - Rod sliding issues;

4 - Damaged/worn out needle or nozzle;

5 - Needle stuffing box is too tight.

1 - Rod sliding issues;

2 - Needle / stuffing box sliding problems;

3 - Rear air stuffing box is worn out;

4 - Ribbed or scratched valve body;

5 - Worn out valve body O-ring.

1 - Dirty front rod;

2 - Worn stuffing box or front rod.

1 - Clean and lubricate front rod;

2 - Replace valve body including the rod.

1 - Properly lubricate the rear rod with mineral oil;

2 - Adjust the stuffing box properly (minimum needle

sliding friction);

3 - Replace rear set screw;

4 - Replace valve body;

5 - Replace valve body O-ring.

1 - Clean needle and nozzle properly;

2 - Insert the spring and/or screw the needle-adjusting

handwheel back on;

3 - Properly lubricate the rear and front rods with mineral oil;

4 - Replace needle and nozzle;

5 - Adjust the stuffing box properly (minimum needle

sliding friction).

1 - Nozzle and needle are not clean;

2 - Stuffing box has not been properly adjusted/set;

3 - Cap with damaged air holes, damaged nozzle, or a

worn out/damaged needle.

1 - Carefully clean the cap/nozzle/needle paying

attention to clean nozzle holes completely

(use cleaning kit 90109/W);

2 - Adjust the stuffing box properly (minimum needle

sliding friction);

3 - Replace needle/nozzle/cap set.

1 - Thoroughly clean the nozzle and sealing cone to the body;

2 - Tighten the nozzle properly;

3 - Tighten the ring nut and cap properly;

4 - Replace the nozzle;

5 - Replace the deflector;

6 - Adjust the stuffing box properly (minimum needle

sliding friction);

7 - Replace the stuffing box needle;

8 - Properly tighten the cup or cup coupling.

Air loss from the E.A.

flow regulator / blocked

handwheel

(For Carbonio EVO

models only)

1 - Air loss from the handwheel, torn gasket;

2 - Blocked handwheel.

1 - Replace The E.A. flow regulator;

2 - Lubricate the part and replace the E.A. flow adjuster.

Summary of Contents for Walcom GENESI CARBONIO 360 EVO HALO BASE

Page 2: ...2...

Page 7: ...7 IT E G R K I P L Cg C M E D C U E G A R K I P L Cg M E GENESICARBONIO360EVO V Z M I...

Page 13: ...13 EN E G R K I P L Cg C M E D C U E G A R K I P L Cg M E GENESICARBONIO360EVO V Z M I...

Page 19: ...19 DE E G R K I P L Cg C M E D C U E G A R K I P L Cg M E GENESICARBONIO360EVO V Z M I...

Page 25: ...25 FR E G R K I P L Cg C M E D C U E G A R K I P L Cg M E GENESICARBONIO360EVO V Z M I...

Page 31: ...31 ES E G R K I P L Cg C M E D C U E G A R K I P L Cg M E GENESICARBONIO360EVO V Z M I...

Page 37: ...37 PT E G R K I P L Cg C M E D C U E G A R K I P L Cg M E GENESICARBONIO360EVO V Z M I...

Page 40: ...40 RUS 1 2 ATEX 0 85 A Walcom...

Page 41: ...41 RUS pH 6 8 43 C UNI EN 1953 5 4 85 C 90109 W...

Page 43: ...43 RUS E G R K I P L Cg C M E D C U E G A R K I P L Cg M E GENESICARBONIO360EVO V Z M I...