SECTION 1

INSTALLATION

1.1) SAFETY

LABELING AND WARNING SIGNS

The words

DANGER, WARNING

and

CAUTION

are used to

identify the levels of seriousness of certain hazards. It is

important that you understand their meaning. You will notice

these words in the manual as follows :

DANGER

Immediate hazards that

WILL

result in death, serious

bodily injury and/or property damage.

WARNING

Hazards or unsafe practices that CAN result in

death, bodily injury and/or property damage.

CAUTION

Hazards or unsafe practices that

CAN

result in bodily

injury and/or property damage.

1.2) IMPORTANT

INFORMATION

WARNING

Non-observance of the safety regulations outlined

in this manual will potentially lead to consequences

resulting in death, serious bodily injury and/or

property damage.

a) It is the homeowner’s responsibility to engage a

qualified technician for the installation and

subsequent servicing of this boiler;

b) Do not store gasoline or any other flammable

substances, such as paper, carton, etc. near the

boiler;

c) Ask the technician installing your boiler to show and

explain to you the main disconnect switch or circuit

breaker;

d) Before calling for service, be sure to have the

information page (p. 8) of your manual close by in

order to be able to provide the contractor with the

required information, such as the model and serial

numbers of the boiler.

WARNING

Installation and repairs performed by unqualified

persons can result in hazards to them and to

others. Installations must conform to local codes

or, in the absence of same, to codes of the country

having jurisdiction.

The information contained in this manual is

intended for use by a qualified technician, familiar

with safety procedures and who is equipped with

the proper tools and test instruments.

Failure to carefully read and follow all instructions

in this manual can result in death, bodily injury

and/or property damage.

1.3)

DANGER OF FREEZING

CAUTION

If your boiler is shut down during the cold weather

season, water pipes may freeze, burst and cause

serious water damage. Turn off the water supply and

bleed the pipes.

If the heater is left unattended during the cold weather

season, take the following precautions:

a) Close the main water valve in the house and purge the

pipes if possible. Open all the faucets in the house;

b) Ask someone to frequently check the house during the

cold weather season to make sure that there is sufficient

heat to prevent the pipes from freezing. Tell this person

to call an emergency number if required.

1.4)

HEATING WITH HOT WATER

Your HYDRA electric boiler was carefully assembled and

checked in our plant, so that it will deliver warmth and

comfort to your home for many years to come.

This manual is intended to provide the necessary information

for the installation of the unit, how it functions, and explain

security measures which are particular to this type of

equipment.

It is essential that the persons installing, operating or

adjusting the boiler carefully read this manual, in order to

completely understand and be familiar with the procedures

to be followed.

Any questions relative to the operation, maintenance or

guarantee should be directed to the company where the

equipment was purchased.

Upon completion of the installation, this manual should be

placed back into its original envelope and kept near the

boiler for future reference.

3

Summary of Contents for HYDRA Series

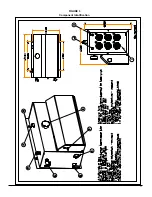

Page 11: ...FIGURE 3 Identification des composantes 11...

Page 12: ...FIGURE 4 Sch ma type d une installation une zone 12...

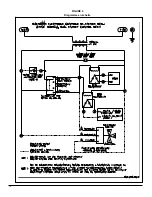

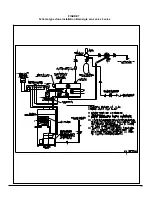

Page 13: ...FIGURE 5 Diagramme lectrique 13...

Page 14: ...FIGURE 6 Diagramme en chelle 14...

Page 15: ...FIGURE 7 Sch ma type d une installation Bi nergie sans valve 3 voies 15...

Page 16: ...FIGURE 8 Sch ma type d une installation Bi nergie avec valve 3 voies 16...

Page 17: ...17 COMPOSANTES ET PI CES DE REMPLACEMENT...

Page 18: ...LISTE DE PI CES HYDRA B50080 Rev B 18...

Page 30: ...FIGURE 3 Component Identification 11...

Page 31: ...FIGURE 4 Typical Diagram of a Single Zone Installation 12...

Page 32: ...FIGURE 5 Electrical Diagram 13...

Page 33: ...FIGURE 6 Ladder Diagram 14...

Page 34: ...FIGURE 7 Typical Diagram of a Dual Energy Installation without 3 way Valve 15...

Page 35: ...FIGURE 8 Typical Diagram of a Dual Energy Installation with 3 way Valve 16...

Page 36: ...17 COMPONENTS AND REPLACEMENT PARTS...