6.

The flow of water through the system must be sufficient

to continuously discharge the energy generated by the

boiler. If not, the High Limit protector will disconnect all

the electric elements and a more or less frequent

cycling mode will be established by the Safety Control

(see the Technical Specifications Table, p. 10);

7.

In order to ensure satisfactory water flow, the friction in

the piping system must not exceed the capacity of the

circulator;

8.

After having completed all piping connections, run water

through the system and purge the air. The automatic

vent should be in operation.

Note: Remove the panel on the right side of the unit and

check to see if the elements and the temperature sensor are

watertight.

1.9)

ELECTRIC POWER SUPPLY

WARNING

Risk of fire.

The conductor sizing must conform to the last

edition of the local or national codes.

Failure to follow this rule can result in death,

bodily injury and/or property damage.

All electrical wiring must conform to the standards and

regulations in force and the Canadian Electrical Code CSA

C22.1.

Electrical power to the boiler must come from a 120/240V 60

Hz, single phase, 3-wire, grounded circuit, protected by an

appropriately sized breaker, based on the total rating of the

boiler. Refer to the boiler nameplate and the technical

specifications in this manual, p. 10, to select the proper

breaker and determine the wire size.

Power supply to the unit can be made using copper or

aluminum wires. The wire size must be decided in

accordance to unit power consumption, the over current

protection type and capacity, the wire type and length, and

the environment where the unit is installed. If an aluminum

wire is used, other precautions (such as the use of a DE-OX

inhibitor) must be taken to insure the conformity of the

installation. In all cases, all the factors affecting the wire

gauge must be considered and the installation codes

followed.

The exterior of the unit must have an uninterrupted ground to

minimize the risk of bodily harm. A ground terminal is

supplied with the control box for that purpose.

In the event that wires inside the unit require replacement,

these must be as same type as originals. (Copper wiring

only).

1.9.1) Connecting the circulating pump

The electronic circuit is designed in such a way that the

circulator functions based on demand by the thermostat, or if

a high limit condition is detected. Refer to Figure 4, page 12

for the connecting of the circulating pump.

1.9.2) Connecting

the

thermostat

Single heating zone

Connect the low voltage thermostat to W1 and R terminals

located inside the control panel on the electronic board, as

represented on Figure 5, p. 13.

Multiple heating zones

Connect the contacts of the motorized valves or pump

controls to W1 and R terminals inside the control panel on

the electronic board.

The anticipator inside the thermostat must be adjusted

according to the electrical load connected to the thermostat.

1.9.3) Thermostat heat anticipator adjustment (if

required)

Certain thermostats are equipped with a heat anticipator that

must be adjusted according to the instructions supplied.

This is to ensure that the heating mode is comfortable and

economical.

Generally speaking, on a single stage thermostat, a reading

of the current must be taken with an ammeter as follows:

1) Move the anticipator to its highest setting, rendering

it ineffective.

2) Remove the wire from the “W1” terminal and

connect an ammeter between the terminal and the

wire.

3) Call for heat by raising the set point on the

thermostat and allow the boiler to run for 3 to 4

minutes to reach its peak output.

4) Once the current has stabilized, a reading should

be taken and the anticipator adjusted to that value.

If longer heating cycles are desired, the anticipator

can be set to a higher value

1.9.4) Connecting the outdoor sensor

Mount the sensor on an outside wall, protected from direct

sunlight, so that it will accurately measure the outside

temperature. Install 2 only #20 wires between the outdoor

sensor and the terminals identified as S1 and S2 on the

electronic board terminal.

5

Summary of Contents for HYDRA Series

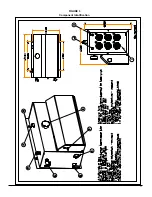

Page 11: ...FIGURE 3 Identification des composantes 11...

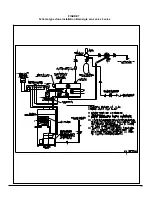

Page 12: ...FIGURE 4 Sch ma type d une installation une zone 12...

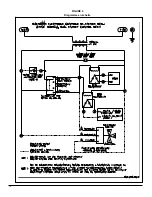

Page 13: ...FIGURE 5 Diagramme lectrique 13...

Page 14: ...FIGURE 6 Diagramme en chelle 14...

Page 15: ...FIGURE 7 Sch ma type d une installation Bi nergie sans valve 3 voies 15...

Page 16: ...FIGURE 8 Sch ma type d une installation Bi nergie avec valve 3 voies 16...

Page 17: ...17 COMPOSANTES ET PI CES DE REMPLACEMENT...

Page 18: ...LISTE DE PI CES HYDRA B50080 Rev B 18...

Page 30: ...FIGURE 3 Component Identification 11...

Page 31: ...FIGURE 4 Typical Diagram of a Single Zone Installation 12...

Page 32: ...FIGURE 5 Electrical Diagram 13...

Page 33: ...FIGURE 6 Ladder Diagram 14...

Page 34: ...FIGURE 7 Typical Diagram of a Dual Energy Installation without 3 way Valve 15...

Page 35: ...FIGURE 8 Typical Diagram of a Dual Energy Installation with 3 way Valve 16...

Page 36: ...17 COMPONENTS AND REPLACEMENT PARTS...