SECTION 2

OPERATION

2.1)

ADJUSTMENTS AND START-UP

CAUTION

The boiler must be filled with water and all air purged

from the system, before turning on the power.

If the power is turned on before the boiler is filled with

water, the elements will become seriously damaged.

1.

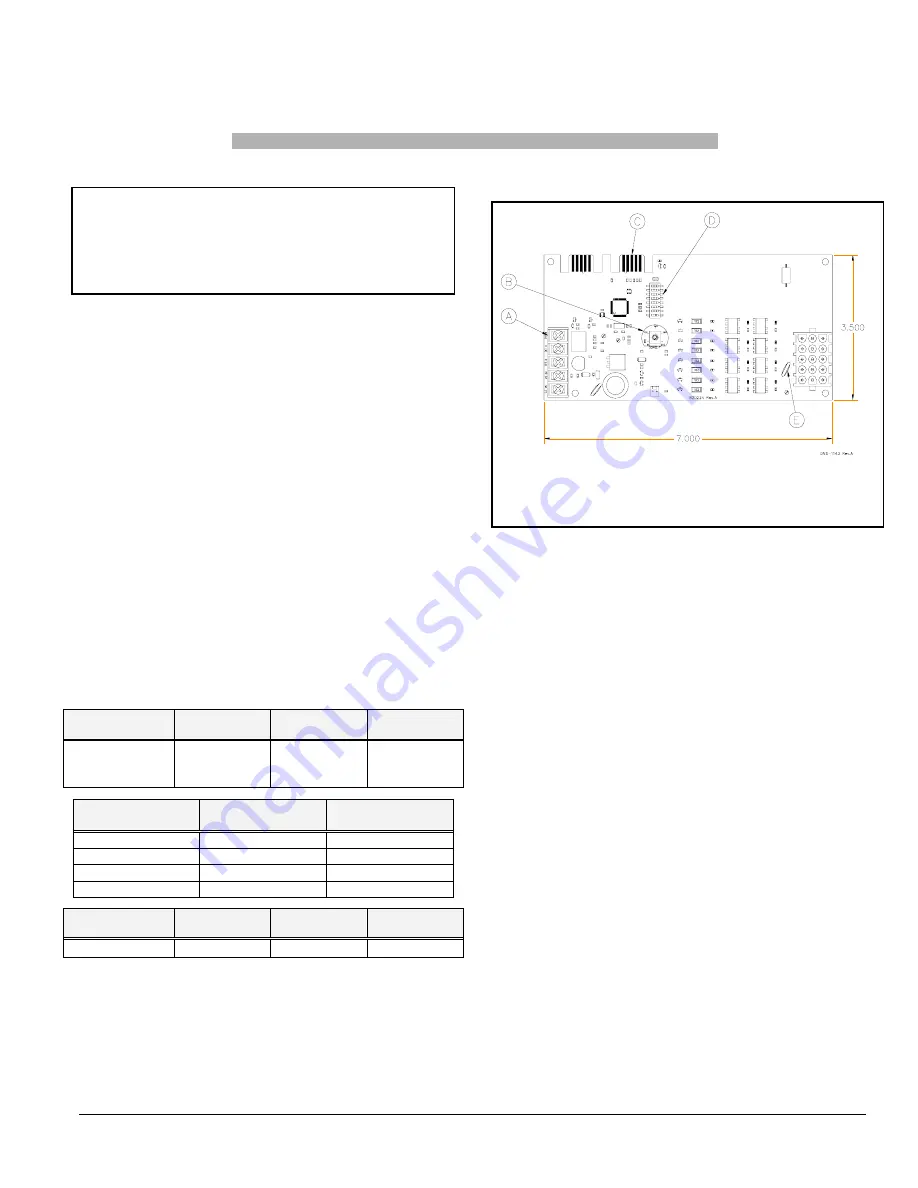

With the help of a small screwdriver, adjust the boiler

temperature screw on the board potentiometer located

on the control board, to between "90°F - 120°F - 150°F -

180°F - 210°F" (see Figure 1, item B);

2.

In the event that the modulating capacity feature of

the boiler is desired,

an outdoor sensor will need to be

installed and wired onto the Hydra electronic board

(terminals S1 and S2). Once the outdoor sensor is wired

to the board, the boiler capacity will modulate if the

outdoor air temperature is between -10

˚

C (14

˚

F) and

10

˚

C (50

˚

F) (see figure 2, p. 9 for more details on

modulation). If capacity modulation of the boiler is not

required for the application, do not proceed with the

installation of the outdoor sensor and leave the

terminals S1 and S2 unwired.

3.

Check if the dip switches "NUMBER OF ELEMENTS"

are in the proper position. Refer to Table 2 and Figure 1,

item D to determine the position of the dip switch, based

on the power rating;

4.

Turn on the power;

5.

Adjust room thermostat according to the required

temperature.

TABLE 2

DIP SWITCHES POSITION

Dip switch 1

Dip switch 2

Dip switch 3

New Hydra with

immersed

sensor

OFF ON ON

Number of

elements

Dip switch 4

Dip switch 5

3 OFF

OFF

4 OFF ON

5 ON

OFF

6 ON ON

Dip switch 6

Dip switch 7

Dip switch 8

Not used

OFF

OFF

OFF

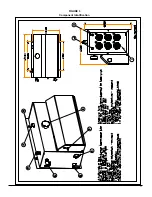

FIGURE 1

HYDRA ELECTRONIC BOARD

A: BOARD TERMINAL STRIP

B: POTENTIOMETER

C: TROUBLESHOOTING PORT

D: DIP SWITCHES FOR BOARD CONFIGURATION

E: FUSE 2A (AUTO-RESET)

2.2) CHECKING

THE

CONTROLS

Operational Controls

After having made sure that the boiler is completely filled

with water and that there is no call for heat, turn on the

power to the unit.

For this verification, disconnect the outdoor sensor from the

S1 and S2 terminals of the Hydra electronic board. As a

result, all the elements will remain functional, regardless of

the outside temperature;

Set the thermostat in the house to 30°C (85°F). The

circulator should start-up and the elements should start

sequentially, one by one (randomly), at approximately 15

second intervals. Pilot lights located on the control board

provide a visual check of the operation of the boiler;

The circulator stays on for as long as there is a call for heat;

By observing the temperature indicator, allow the water

temperature to rise to 60°C (140°F). Then, turn the electronic

Limit Control counter clockwise to 32°C (90°F). The

elements will stop sequentially, one by one, at 1 second

intervals between each. Now, the water temperature must be

adjusted with the "90°F - 120°F - 150°F - 180°F - 210°F" set

screw on the electronic board.

Once the verification is completed, reconnect the outdoor

sensor to S1 and S2 of the Hydra electronic board (if

required).

6

Summary of Contents for HYDRA Series

Page 11: ...FIGURE 3 Identification des composantes 11...

Page 12: ...FIGURE 4 Sch ma type d une installation une zone 12...

Page 13: ...FIGURE 5 Diagramme lectrique 13...

Page 14: ...FIGURE 6 Diagramme en chelle 14...

Page 15: ...FIGURE 7 Sch ma type d une installation Bi nergie sans valve 3 voies 15...

Page 16: ...FIGURE 8 Sch ma type d une installation Bi nergie avec valve 3 voies 16...

Page 17: ...17 COMPOSANTES ET PI CES DE REMPLACEMENT...

Page 18: ...LISTE DE PI CES HYDRA B50080 Rev B 18...

Page 30: ...FIGURE 3 Component Identification 11...

Page 31: ...FIGURE 4 Typical Diagram of a Single Zone Installation 12...

Page 32: ...FIGURE 5 Electrical Diagram 13...

Page 33: ...FIGURE 6 Ladder Diagram 14...

Page 34: ...FIGURE 7 Typical Diagram of a Dual Energy Installation without 3 way Valve 15...

Page 35: ...FIGURE 8 Typical Diagram of a Dual Energy Installation with 3 way Valve 16...

Page 36: ...17 COMPONENTS AND REPLACEMENT PARTS...