SURFOX 304 User’s Guide

17

11

Safety features

D) AC/DC settings on the SURFOX machine

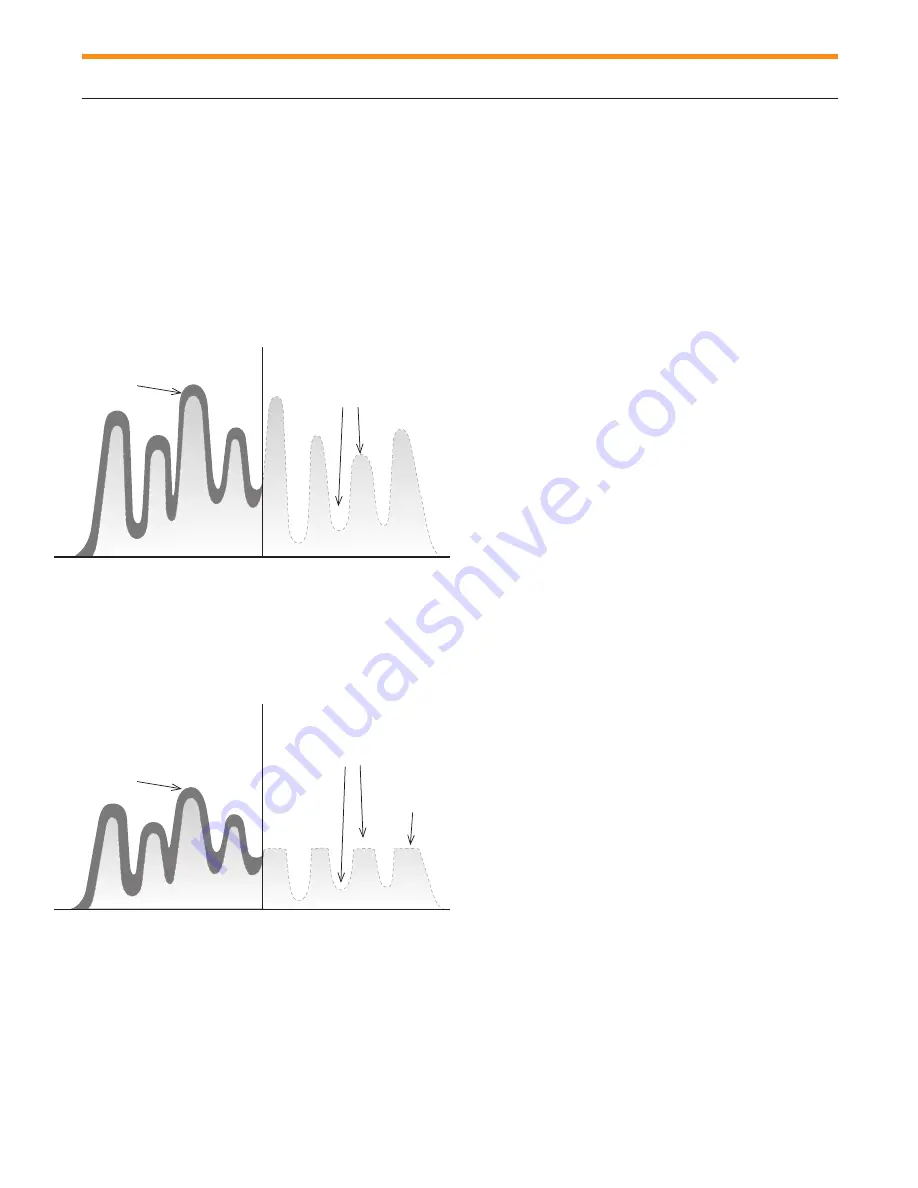

Example of cleaning and passivation with SURFOX in AC

mode:

Example of cleaning and passivation with SURFOX in DC

mode:

E) Welds that cannot be cleaned

If the area around the weld is black (not blue) from contami-

nation, this is a problem of high heat generated during the

welding process. The contaminated areas do not conduct

electricity. If there is no conductivity in the material, the

SURFOX system cannot work.

If there are two welds on top of the other, the structure of

the material has been seriously altered. These areas may

not be cleaned.

The quality of the weld is critical. The better the weld, the

easier it will be to clean.

Oxide

layer to be

removed

Oxide

layer to be

removed

Alteration of the

material due to

the DC setting

Cleaning and passivation is

perfect. Cleans every crack in

the material.

Cleaning and passivation is

perfect. Cleans every crack in

the material.

BEFORE

BEFORE

AFTER

AFTER

Microscopic view of the material

Microscopic view of the material

Summary of Contents for SURFOX 304

Page 2: ......

Page 21: ...SURFOX 304 User s Guide 19...

Page 40: ...38...

Page 59: ...SURFOX 304 User s Guide 57...

Page 78: ...76 Notes Notas...

Page 79: ...77 Notes Notas...