4

Assembly / Installation

This spray gun is delivered in completely assembled condition. Before taking the

spray gun into operation perform the following preparations:

4.1

Mounting of Spray Gun

Install the gun in a suitable and stable mounting device as shown in the following

example:

Use mounting pin 1, diameter 12 mm.

Other mounting devices upon request.

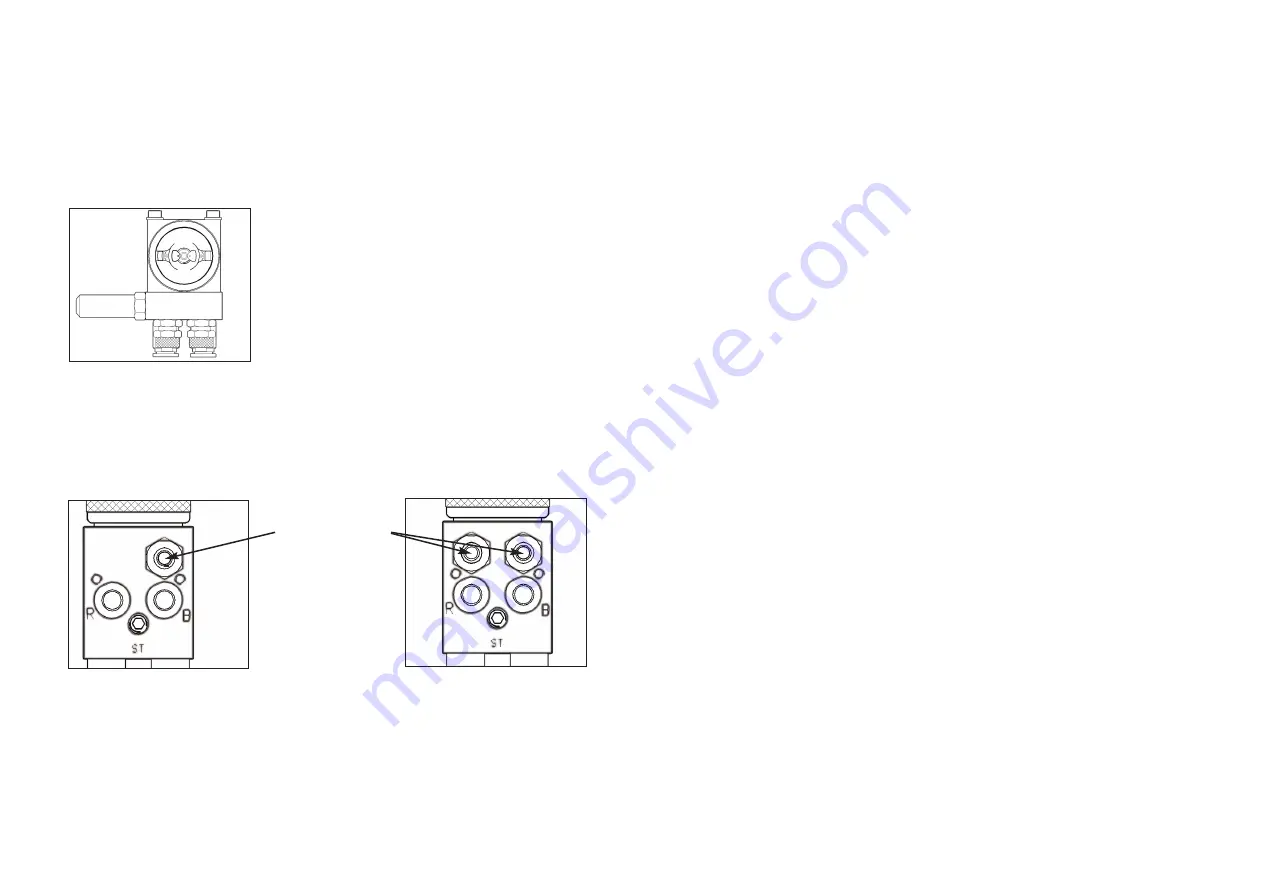

4.2

Connection of Input Lines

Warning

Make sure not to confuse the control and atomizing air (round - and wide/flat air) con-

nections -risk of injury.

Standard version

Circulation version

Material inlet

Inlets:

R - Round jet

B - Wide/flat jet

ST - Control air

The spray gun is now properly installed and connected and ready for operation.

5

Operational Handling

5.1

Safety Warnings

Please pay special attention to the following safety warnings prior to taking this

spray gun into operation!

• Wear proper respiratory protection masks and protective overalls, whenever you

are operating this spray gun. Air-borne particles represent a health hazard.

• Make sure to wear suitable haering protectors. The gun produces sound levels

of up to 86 dB (A) which may cause hearing defects.

• Open fires, naked lights and smoking prohibited in the working area. Spraying of

readily flammable media such as paints and adhesive compounds is always

accompanied by the risk of fire and explosion.

5.2

Starting / Stopping Requirements

The following requirements must be met before taking this spray gun into operati-

on:

• control air must be available at the gun

• atomizing air (round - and wide/flat air) must be available at the gun

• material pressure must be available at the gun.

Caution

The material pressure shall not exceed

• 6 bar, as, otherwise, the functional reliability of the spray gun will suffer.

Adjust the control air pressure to

• at least 4,5 bar, in order to operate the spray gun.

The operation of the spray gun can be started/stopped by way of the 3/2-way con-

trol valve (see the Operating Instructions of the plant systems manufacturer).

Warning

It is important to remember that the spray gun must be relieved of all pressures

whenever work is terminated. Lines left in pressurized condition could burst, with

their contents likely to injure anybody present nearby.

5.3

Spray Pattern Test

Spray pattern tests should be performed whenever:

• the spray gun is taken into operation for the first time

• the spraying medium is changed

• the spray gun was taken apart for servicing or repairs.

The spray pattern can be tested using a work piece sample, a sheet of metal,

cardboard or paper.

1

l

l

l

5

6

Summary of Contents for 20 545

Page 3: ...PILOT WA 450...