31

30

Repair Kit:

A WALTER repair kit is available for the hand-held spray guns PILOT IV and PILOT

IV GM which comprises all wearing parts:

Repair Kit Art. No.: V 16 004 02 . . 1

Consisting of: air cap (Item 2), material nozzle (Item 3), needle seal packing (Item 5),

material control needle (Item 9), needle retaining nut (Item 10), needle spring

(Item 12), valve spring (Item 17), valve cone (Item 18) and packing (Item 22).

8

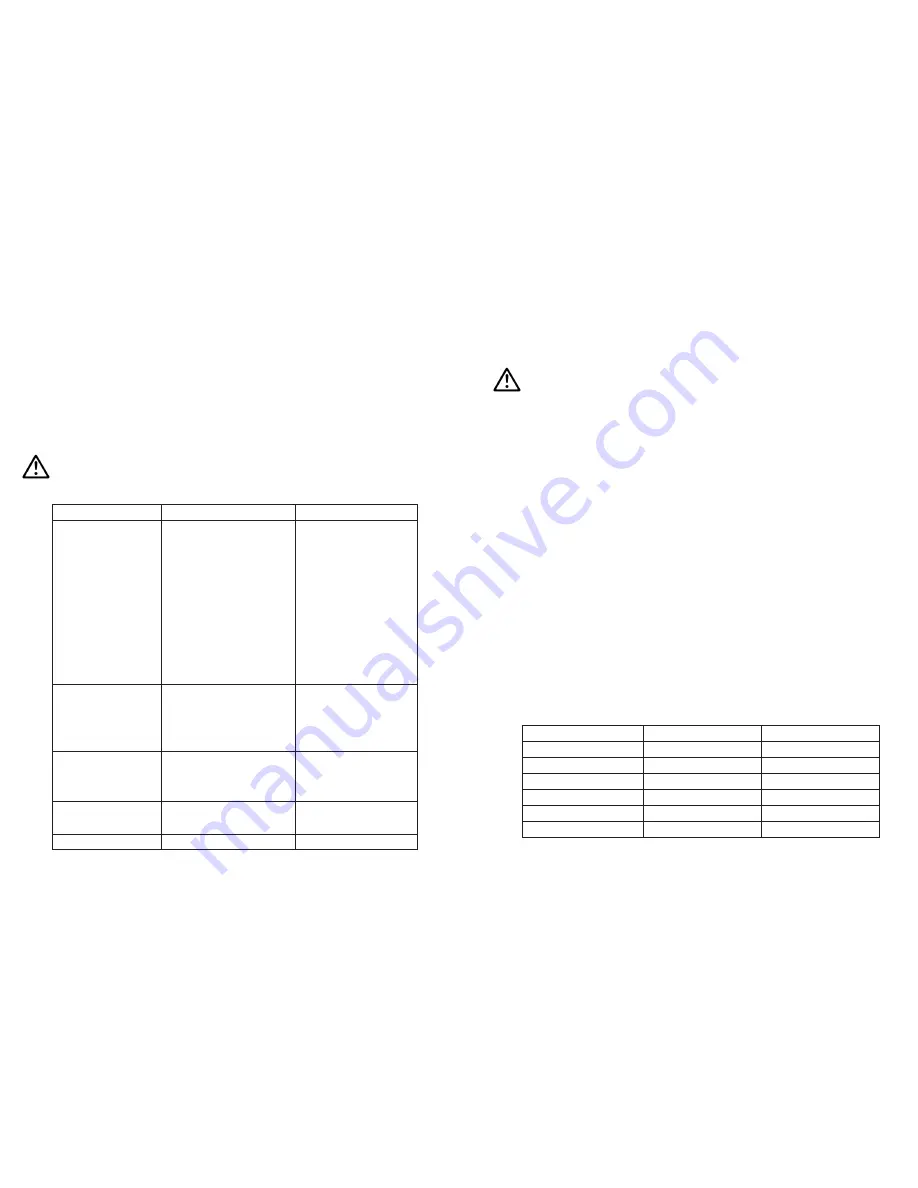

Troubleshooting and Corrective Action

Warning

Prior to any servicing and repair work: Make sure that the spray gun is in unpressu-

rized condition, i.e. the air input must be shut off - if not, imminent risk of injury.

Fault

Cause

Corrective Action

Gun is dripping

Material needle or nozzle fouled

Material needle or nozzle

damaged

Needle packing gland (Item 4)

too tight

Needle spring (Item 11)

defective, possibly broken

Size mismatch between materi-

al needle and nozzle

Adjusting screw (Item 14) tur-

ned too far to the back

Clean - see

5.5 Retooling

the Spray Gun

Replace - see

5.5 Retooling

the Spray Gun

Loosen slightly

Remove material needle and

nee dle spring - see

5.5 ...

Use same diameters

Screw in adjusting screw

slightly

(turn clockwise)

Spray jet pulsating or

unsteady

Level in gravity-feed too low

Gravity-feed cup is tilted too

much during spraying operation

Material nozzle is loose or

damaged

Top-up material level

Keep straight

Tighten

Materialleckage

from Packing Gland

Packing gland too loose

Needle seal packing (Item 5)

damaged

Tighten

Replace

Gun keeps blowing in off

condition

Valve cone (Item 18) damaged

or

Valve shank (Item 19) binds

Replace

Loosen

Spray jet one-side

Horn bores fouled

Clean air cap

9

Disposal of Cleaning / Servicing Substances

Disposal of any such substances must be in accordance with all applicable local and

national regulations, directives and laws.

Warning

Particular attention is drawn to all processing specifications and safety warnings

issued by the manufacturers of spraying and cleaning media.Remember: The

irrproper disposal of any toxic waste material represents a serious threat to the

environment, i.e. to the health of mankind and animal life.

10

Specification Data

Net Weight PILOT IV:

630 g

Net Weight PILOT IV GM:

460 g

Available range

of spray nozzles:

0.5 • 0.8 • 1.0 • 1.2 • 1.5 • 1.8

• 2.0 • 2.5 • 3.0 • 3.5 mm ø

Air Caps*:

two-bore -, four-bore -, six-bore air cap

*other air caps on demand.

Max. Spraying Pressure:

8 bar

Max. Operating Temperature

of the Spray Gun:

43 °C

Sound Level

(measured at a distance

of 1 m from the spray gun)

84 dB (A)

Air Consumption:

Atomising Air Pressure

Round Jet

Flat Jet

1,0 bar

110 l / min

180 l / min

2,0 bar

140 l / min

240 l / min

3,0 bar

170 l / min

280 l / min

4,0 bar

190 l / min

320 l / min

5,0 bar

200 l / min

350 l / min

6,0 bar

220 l / min

390 l / min

Right to effect technical changes reserved.