33

32

Pay attention to the following safety warnings when using the spray gun!

•

Always wear proper respiratory protection masks and protective overalls when

using the spray gun. Airborne particles can damage your health!

•

Always wear suitable hearing protectors in the vicinity of the spray gun. These

spray guns produce sound levels of approximately 85 dB(A) (PILOT Maxi) or

83 dB(A) PILOT Maxi-MP and PILOT Maxi-HVLP).

•

Ensure that the working area is absolutely free from open fires and naked lights

– and that smoking is strictly prohibited. The spraying of flammable liquids (e.g.

paint, adhesives) is always accompanied by the risk of fire and explosion.

•

When spraying materials, keep hands and other parts of the body away from the

nozzle of the gun when it is under pressure. Risk of injury!

•

Relieve the spray gun of all pressures when work is complete. Lines left in a

pressurised condition might burst and their contents are likely to injure persons

standing nearby!

6

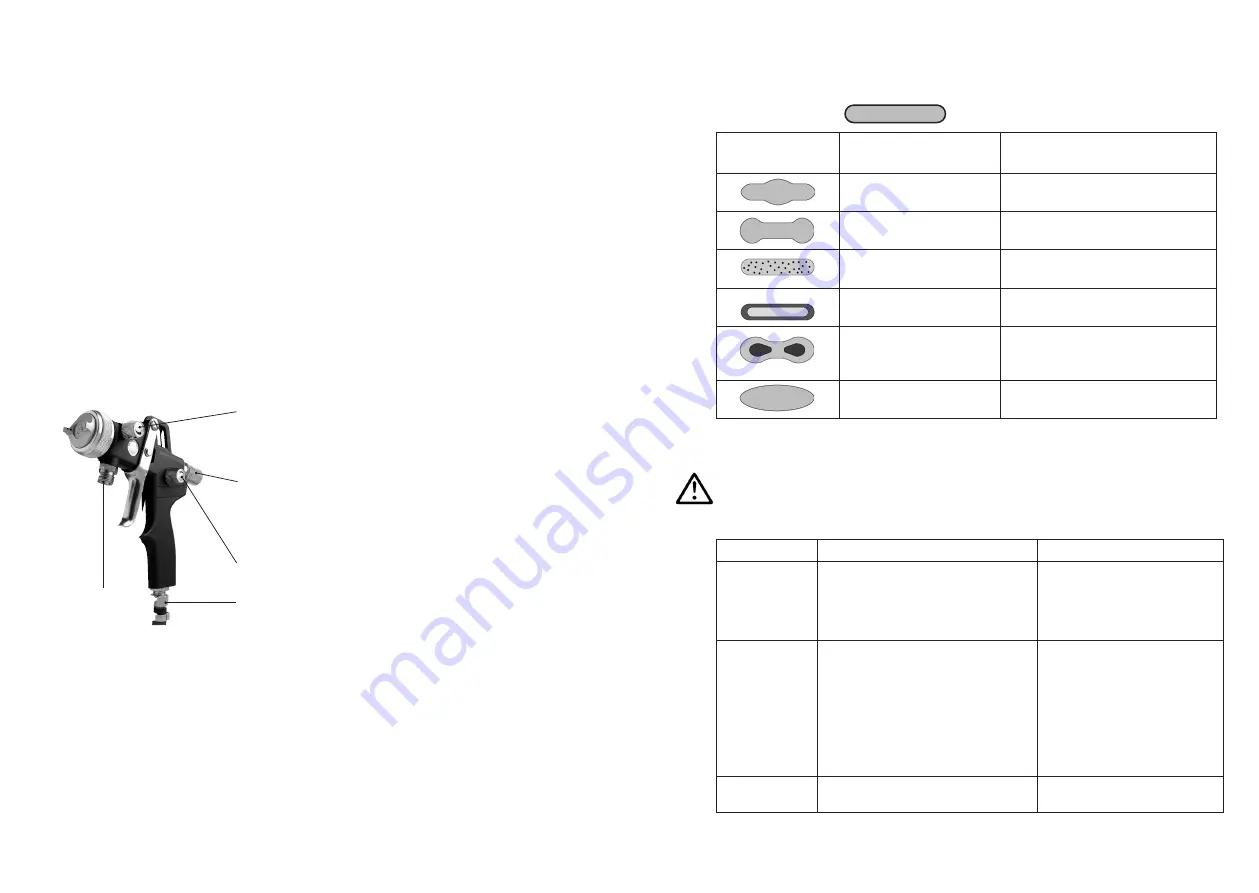

Adjusting the Spray Pattern

The spray pattern of the PILOT Maxi can be changed by adjusting the gun as follows:

Adjusting the Material Pressure

Pressure-Feed Cup Version:

The material pressure can be adjusted with a screwdriver at the restriction valve.

Material Connection Version:

The material pressure can be adjusted only at the controls of the pumping system or

at the material pressure tank. Please observe the operating instructions and safety

warnings issued by the manufacturers concerned.

Air connection

Setting a wide or round jet:

The adjusting screw is used to adjust the width of the spray jet. The

jet can be changed to a wide jet by turning the screw anti-clockwise

(screwing out) and to a round jet by turning the screw clockwise

(screwing in).

Adjusting the atomising air flow rate

The atomising air flow rate can be adjusted by screwing the

adjusting screw in or out.

Setting the material flow rate:

The material flow rate can be adjusted by screwing the adjusting

screw in or out. The flow rate is increased by turning the screw anti-

clockwise (screwing out) and decreased by turning the screw

clockwise (screwing in).

Material

connection

6.1

Correction of Spray Pattern Imperfections

The following table shows how to correct a defective spray pattern.

Spray pattern

test

Deviation

Necessary adjustment

Swollen centre

• Spray jet should be flatter

Swollen ends

• Spray jet should be rounder

Coarse pearl effect

• Increase atomising air pressure

Unduly thin paint layer

in centre

• Decrease atomising air pressu-

re

Split centre

• Increase nozzle diameter

• Reduce atomising air pressure

• Increase material pressure

Crowned centre

• Decrease material pressure

• Increase atomising air pressure

7

Trouble shooting

Warning

Prior to any retooling the spray gun should be depressurized state, i. e. atomising air

as well as the material pressure - risk of injury.

Fault

Cause

Remedy

Dripping from

the nozzle

The nozzle or needle are dirty or

damaged

The setting screw (pos. 18) is tur-

ned too far to the back

• Clean or replace

• Adjust by turning clockwise

Pulsating or

unsteady jetl

Not enough material in the tank

Cup is tilted too much

Material nozzle loose or damaged

Material too heavy for the suction

cup

• Top-up material level

• Keep it level

• Tighten or replace (pos. 5)

• Use pressure tanks or

pumps

The gun blows

in off position

Valve cone (pos. 11) or

valve stem (pos. 10) damaged

• Replace

desired spray pattern