35

34

8

Retooling and repairs

If a jet contour other than already described is desired, the spray gun has to be

retooled. The suitable material air cap, material nozzle and needle-combination form

together a unit - the nozzle set. Always change the complete insert assmbly to

maintain the desired finish quality.

Warning

Prior to any repairs or replacements: Make sure that the spray gun is in depressurized

condition, i.e. all air and material inputs must be shut off - if not, imminent Risk of

Injury.

Note

In order to perform the following procedures, please refer to the exploded diagram at

the beginning of these operating instructions.

Replacement of the material nozzle and the air cap

1. Unscrew the air cap nut (pos. 1).

2. Remove the air cap (pos. 2).

3. Unscrew the material nozzle (pos. 3) from the gun body (use size 13 wrenth).

4. Remove the intermediate ring (pos. 4) from the material nozzle.

The installation of the new nozzle insert assembly and of the remaining parts in

reverse order.

Replacement of the material needle

1. Unscrew the adjusting screw (pos. 18).

2. Remove the needle spring (pos. 17).

3. Pull the material needle (pos. 16) out off the gun body.

Reassemble in reverse order. An initial air inlet is not necessary.

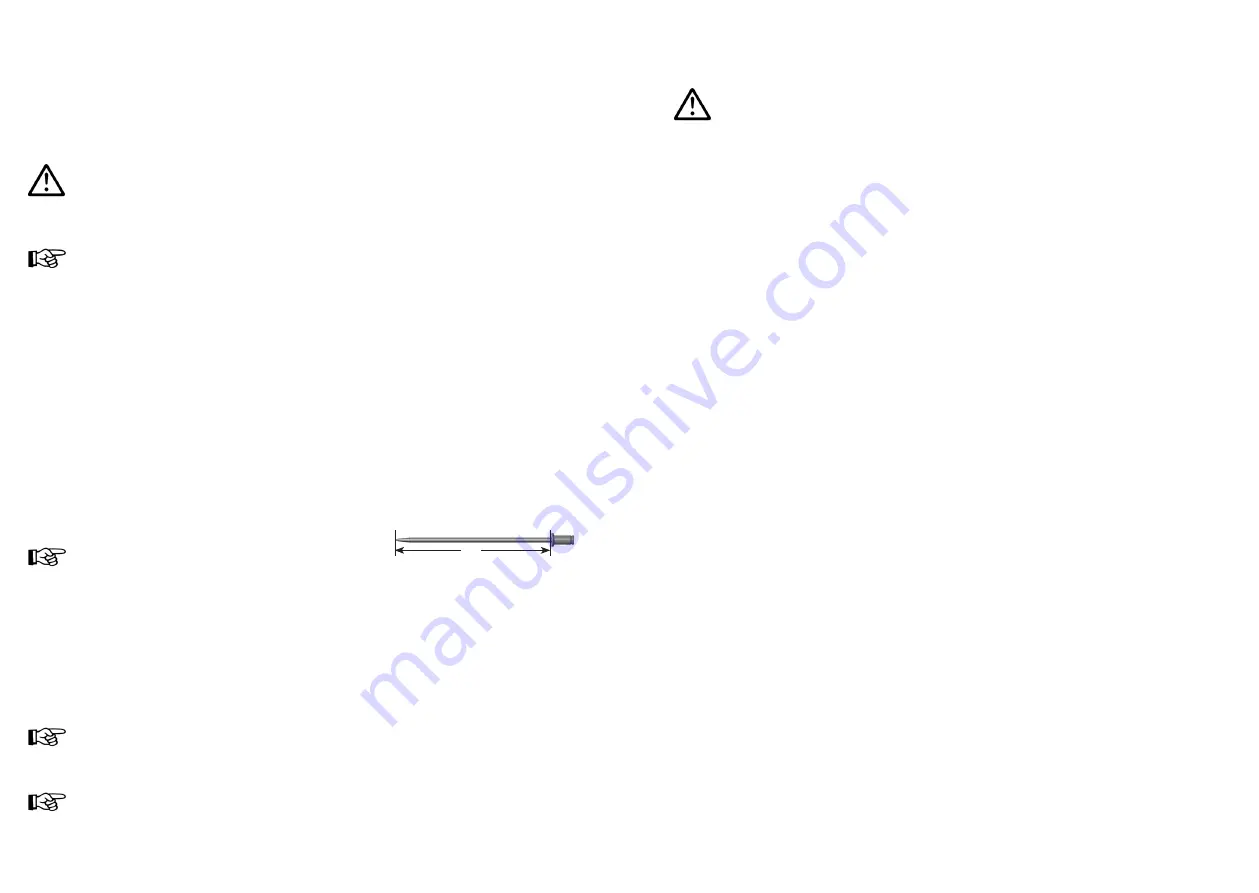

Note

The needle setting for the PILOT Maxi (Gravity-feed cup) is X = 141,5 mm and for the

PILOT Maxi (Material connection) X = 147,5 mm from the needle tip to the driving

bushing.

Replacement of the defective needle packing

1. Disassemble the material needle as described above.

2. Remove the knurled screw (pos. 32).

3. Remove the needle packing (pos. 33) including the O-ring (pos. 34).

Reassemble in reverse order.

Note

Never reinstall a used needle packing, as otherwise the functional sealing reliability

of the spray gun will not be guaranteed.

Note

All sliding and moveable parts must be lubricated with a non-acidic, non-resinogenic

grease prior to installation.

9 Cleaning

Attention

Do not use any hard, sharp or pointed objects when cleaning the spray gun. Never

immerse the spray gun in solvent or any other cleaning solution. The functional relia-

bility and efficiency of the gun can otherwise not be guaranteed. Clean the PTFE-

coated gun body with a soft cloth. WALTHER Spritz- und Lackiersysteme is not

responsible for any damage resulting from improper cleaning.

The gun does not need to be dismantled for cleaning.

1. Fill the cleaned material container / gravity-feed cup / syphon -feed cup / sus-

pended pressure cup or the cleaned pressure tank with a cleaning fluid

compatible with the sprayed material.

2. Operate the spray gun.

3. Do not stop the spray gun until clear cleaning fluid emerges from the nozzle.

The entire system should then be depressurised until the gun is used again. Clean

the spray gun only with cleaning agents which have been recommended by the

manufacturer of the sprayed material and which do not contain the following

constituents:

•

halogenated hydrocarbons (e.g. 1,1,1-trichloroethane, methylene chloride, etc.)

•

acids and acidic cleaning fluids

•

regenerated solvents (so-called cleaning thinners)

•

paint removers

The above-mentioned constituents cause chemical reactions on electroplated

components, resulting in corrosion damage.

Clean the spray gun

•

before each change of spraying material

•

at least once a week or

•

several times a week if required by the spraying medium and depending on the

degree of fouling.

Detailed

Cleaning

1. Disassemble the spray gun

2. Clean the air cap and the material nozzle with a soft brush and cleaning fluid.

3. Clean all other components and the gun body with a soft cloth and cleaning fluid.

4. Coat the following parts with a thin layer of grease:

•

needle spring

•

all sliding parts and bearing points.

The moving internal parts must be greased at least once a week.

The springs should always be coated with a thin layer of grease. For this, always use

a non-acidic, non-resinogenic grease and a soft brush. Assemble the gun again in

reverse order.

x