34

35

•

paint removers

The above-mentioned constituents cause chemical reactions on electroplated com-

ponents, resulting in corrosion damage.

Clean the spray gun

•

before each change of spraying material

•

at least once a week or

•

several times a week if required by the spraying medium and depending on the

degree of fouling.

Complete Cleaning

1. Disassemble the spray gun

2. Clean the air cap and the material nozzle with a soft brush and cleaning fluid.

3. Clean all other components and the gun body with a soft cloth and cleaning fluid.

4. Coat the following parts with a thin layer of grease:

•

needle spring

•

all sliding parts and bearing points.

The moving internal parts must be greased at least once a week.

The springs should always be coated with a thin layer of grease. For this, always use

a non-acidic, non-resinogenic grease and a soft brush.

Assemble the gun again in reverse order.

8

Troubleshooting

Warning

Prior to any repairs/replacements: Make sure that the spray gun is in unpressurized

condition, i.e. the air and material input must be shut off - if not, imminent Risk of

Injury.

Fault

Cause

Remedy

Gun is dripping

Nozzle or needle damaged

Nozzle or needle clogged

Needle packing gland (item 3.1)

too tight

Replace

Clean

Loosen slightly

Pulsating or

unsteady spray jet

Level in material tank too low

Gravity cup is tilted too much

Material nozzle(item 2) loose or

damaged

Top-up

Keep straight

Tighten or Replace

Gun keeps blowing

in off-position

Valve spring (item 8) or

valve cone (item 7) damaged

Replace

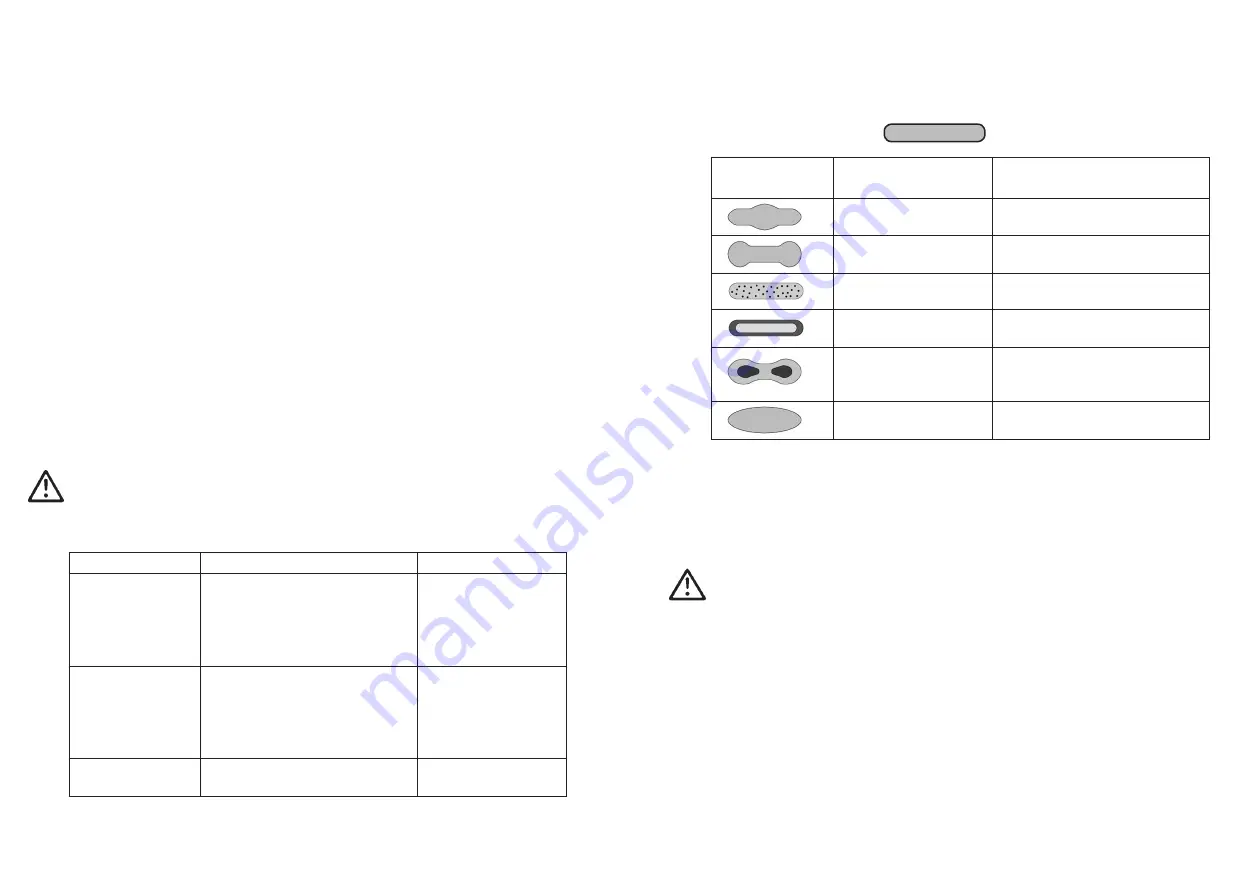

8.1

Correction of Spray Pattern Imperfections

The following table shows how to correct a defective spray pattern.

Spray pattern

test

Fault

Necessary adjustment

Swollen centre

• Spray jet should be flatter

Swollen ends

• Spray jet should be rounder

Coarse pearl effect

• Increase atomising air pressure

Unduly thin paint

layer in centre

• Decrease atomising air pressure

Split centre

• Increase nozzle diameter

• Reduce atomising air pressure

• Increase material pressure

Split centre

• Decrease material pressure

• Increase atomising air pressure

9

Disposal of Cleaning and Servicing Substances

The disposal of substances used for cleaning and servicing should be in accor-

dance with local, national and international laws and directives.

Warning

Particular attention should be paid to the spray and cleaning media manufacturers‘

instructions. Improper disposal represents a serious threat to the health of humans

and animals.

Desired Spray Pattern