W

WA

AL

LT

TH

HE

ER

R P

PIIL

LO

OT

T

Betriebsanleitung / Operating Instructions

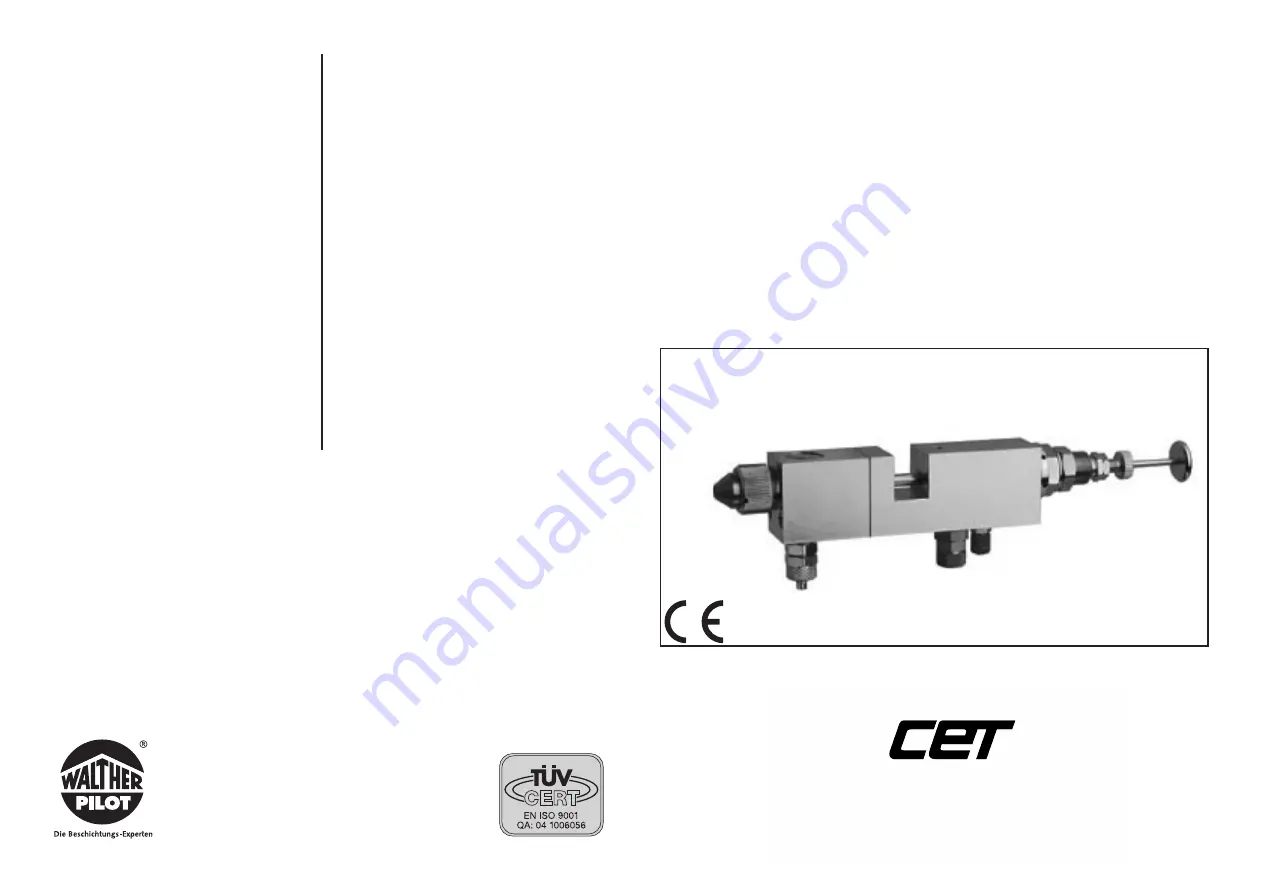

Signierpistole / Marking Gun

P

PIIL

LO

OT

T S

Siig

gn

niie

err 2

20

0 3

35

57

7

Membranausführung / Diaphragm - Version

Das WALTHER PILOT-

Programm

• Hand-Spritzpistolen

• Automatik-Spritzpistolen

• Niederdruck-Spritzpistolen (System HVLP)

• Zweikomponenten-Spritzpistolen

• Materialdruckbehälter

• Drucklose Behälter

• Rührwerk-Systeme

• Airless-Geräte und Flüssigkeitspumpen

• Materialumlaufsysteme

• Kombinierte Spritz- und Trockenboxen

• Absaugsysteme mit Trockenabscheidung

• Absaugsysteme mit Naßabscheidung

• Pulversprühstände

• Trockner

• Zuluft-Systeme

• Atemschutzsysteme und Zubehör

The WALTHER PILOT-

Programme

• Manual spray guns

• Automatic spray guns

• HVLP spray guns

• Two-component spray guns

• Pressure pots

• Pressureless containers

• Agitator systems

• Airless equipment and fluid pumps

• Material circulation systems

• Combined spraying and drying booths

• Exhaust extraction systems with dry filtering

• Exhaust extraction systems with wet filtering

• Powder spraying stands

• Dryers

• Air supply systems

• Breathing masks, breathing equipment and

accessories

WALTHER Spritz- und Lackiersysteme

Kärntner Str. 18-30 • 42327 Wuppertal

D-42306 Wuppertal

Telefon: 0202 / 787-0 • Telefax: 0202 / 787-217

www.walter-pilot.de • Email:info@walther-pilot.de

Summary of Contents for PILOT Signier 20 357

Page 2: ......