31

30

6.1

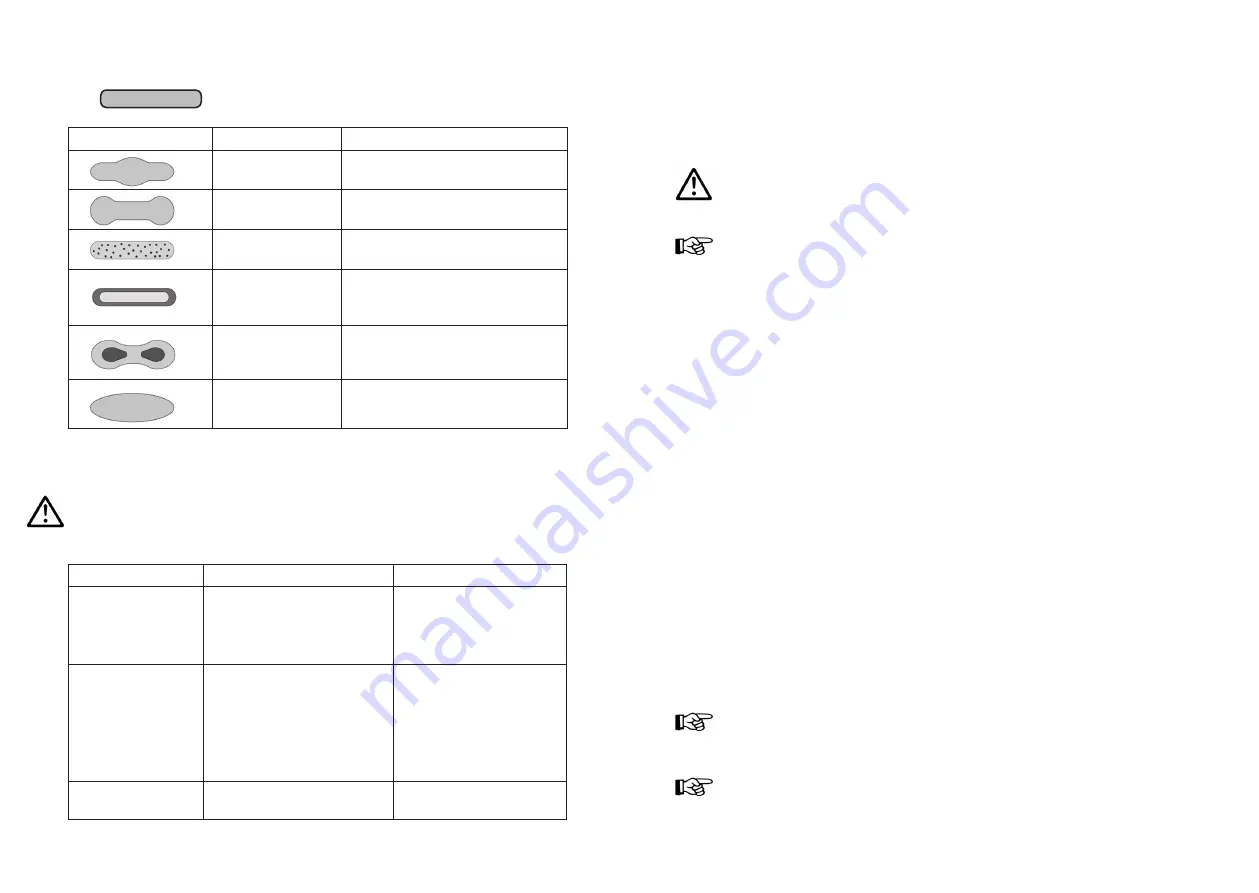

Correcting spray pattern flaws

Spray pattern test

Fault

Necessary adjustment

Swollen centre

• Spray jet should be flatter

Swollen ends

• Spray jet should be rounder

Coarse pearl effect • Increase atomising air pressure

Unduly thin paint

layer in centre

• Decrease atomising air pressure

Split centre

• Increase nozzle diameter

• Reduce atomising air pressure

• Increase material pressure

Split centre

• Decrease material pressure

• Increase atomising air pressure

7

Troubleshooting and fault rectification

Warning

Prior to any seervicing and repair work: Make sure that the spray gun is in unpres-

surized condition, i.e. air input must be shut off - if not, imminent risk of injury.

Fault

Cause

Remedy

Gun is dripping

Material needle or nozzle

soiled or damaged

Spring bushing (N° 18) tur-

ned too far to the back

• Clean or replace

• Adjust by turning clock-

wise

Pulsating or unstea-

dy jet

Not enough material in mate-

rial tank

Cup is tilted too much during

spraying operation

Material nozzle loose or

damaged

• Top-up material level

• Keep it level

• Fasten or replace

Gun keeps blowing

in off-position

Valve cone (N° 15) or

valve stem (N° 14) damaged

• Replace

desireable spray-painting result

8

Conversion and repair

If a jet contour other than those already described is desired, the spray gun has to

be re-tooled. Air cap, material nozzle and needle packing together form a unit - the

nozzle insert assembly. Always change the complete insert assembly to maintain the

desired spray finish quality.

Warning

Prior to any repairs/replacements: Make sure that the spray gun is in unpressurized

condition, i.e. air must be shut off - if not, imminent Risk of Injury.

Note

In order to perform the following procedures, please refer to the exploded diagram at

the beginning of these operating instructions.

Replacement of the material nozzle

and

the air cap

1. Unscrew the air cap nut (N° 1).

2. Remove the air cap (N° 2).

3. Unscrew the nozzle (N° 3) (ws 12) from the gun body (N° 4).

When mounting the nozzle, the material needle should be in a flashed condition.

Reassemble in reverse order.

Replacement of the material needle

1. Unscrew the spring bushing (N° 18).

2. Remove the needle spring (N° 17).

3. Pull the material needle (N° 16) out of the gun body.

Reassemble in reverse order.

For correct initial air adjustment the needle has to be set at 53 mm (Gravity-feed cup)

and 72,5 mm

(Material Connection) measured from the tip to the driving gland.

Replacement of the needle seal

1. Disassemble the needle as described above.

2. Remove the needle packing gland (N° 6).

3. Unscrew the lever shank screw (N° 19) and the lever screw (N° 21) and remove

the trigger (N° 20).

4. Remove the needle seal (N° 5) (Use a thin wire, one end of which is bent into a

hook, for this purpose).

Reassemble in reverse order.

Note

Never reinstall a used needle seal, as otherwise the functional sealing reliability of

the spray gun will not be guaranteed.

Note

All sliding and moveable parts (except the material needle!) must be lubricated with

a non-acidic, non-resinogenic grease prior to installation.