41

40

WALTHER repair kits are available for PILOT WA 400 - WA 430 and the correspon-

ding versions of adhesive coating PILOT WA 470-K - WA 473-K spray guns including

all wearing parts:

Article No.: V 16 400 06 . . 3 (WA 400 / WA 410)

Article No.: V 16 420 03 . . 3 (WA 420 / WA 430)

Article No.: V 16 580 02 . . 3 (WA 470-K - WA 473-K)

Wearing parts are also shown in the listing of replacement parts (in bold face).

8

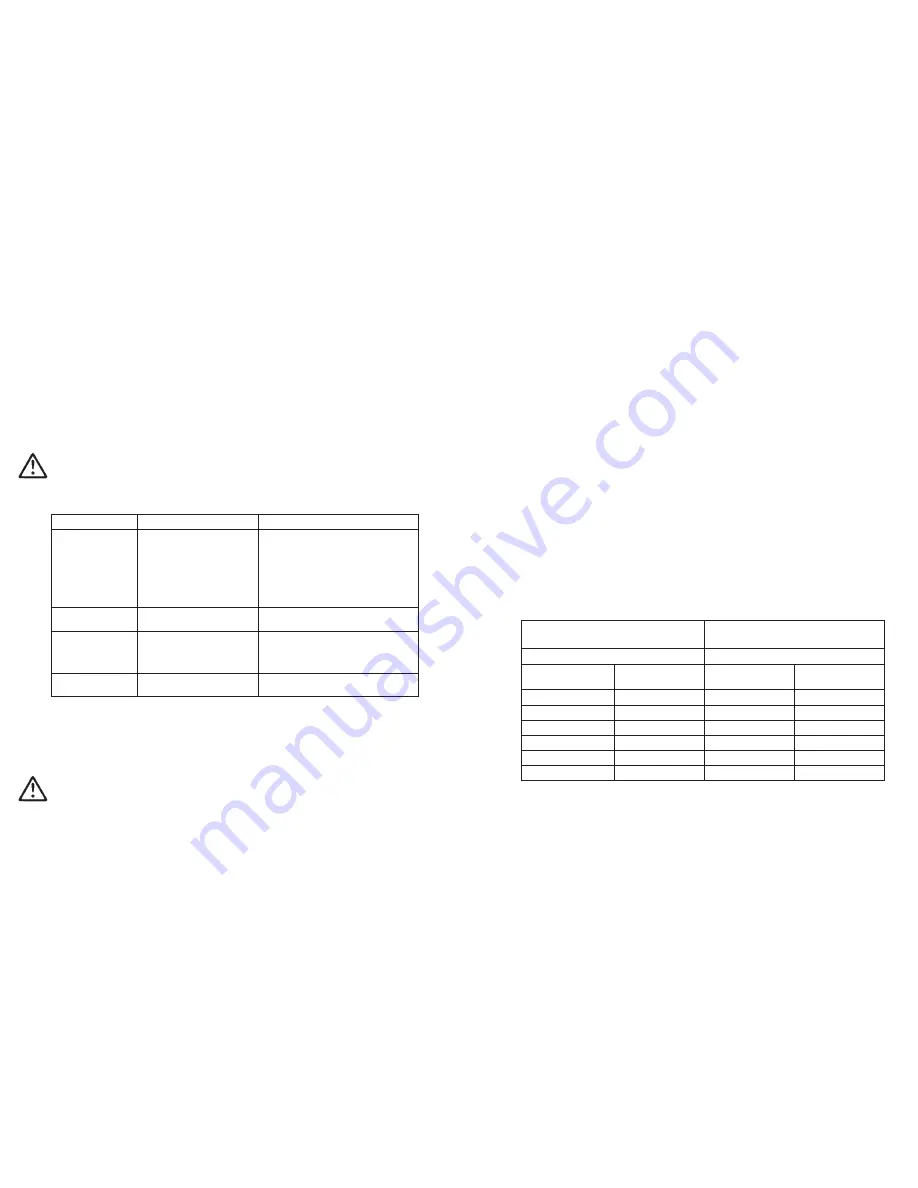

Troubleshooting and Corrective Action

Warning

Prior to any servicing and repair work: Make sure that the spray gun is in unpressu-

rized condition, i.e. all air and material inputs must be shut off - if not, imminent risk

of injury.

Fault

Cause

Remedy

Gun is dripping

Material control nozzle or needle

fouled

Material control nozzle or needle

damaged

Packing screw too tight

see 5.5 Removing Material

Control Nozzle or Needle and cleaning

see 7.2 Replacing Material

Control Nozzle or Needle

Loosen packing screw in (pos. 21) slightly

with a screw driver

Gun fails to open

Control air pressure too low

Increaese control air pressure to at least 4.5

bar

Material leaks from

leakage boring

Needle seal packing leaks

Packing screw too loose

see 7.1 Replacing Needle Seal Packing

Tighten packing screw in (pos. 21) slightly

with a screwdriver

Spray jet pulsating or

unsteady

Level in material tank too low

Top-up material level (see operating instruc-

tions of plant systems manufacturer)

9

Disposal of Cleaning / Servicing Substances

Disposal of any such substances must be in accordance with all applicable local and

national regulations, directives and laws.

Warning

Pay special attention to all processing specifications and safety warnings issued by

the manufacturers of spraying and cleaning media. The improper disposal of any

toxic waste material represents a serious threat to the environment, i.e. to the health

of mankind and animal life.

10

Specification Data

Nozzle Sizes:

0.5 - 0.8 - 1.0 - 1.2 - 1.4 - 1.5 - 1.8 - 2.0 -

2.2 - 2.5 mm ø

Weight:

580 g

Connections:

Atomizing

Air

G

1/4

“

Control

Air

G

1/8

“

Material Inlet

G 1/4 “

Pressure Ranges:

Control Air Pressure

min. 4,5 bar

Material pressure

max. 10 bar

Atomizing Air

max. 8 bar

max. Operating Temperature

of Spray gun

80 °C

Sound Level

(measured at a distance

of 1 m from the spray gun)

86 dB (A)

Air Consumption:

Models PILOT WA 400 / 470-K and

WA 410 / 471-K

Models PILOT WA 420 / 472-K and

WA 430 / 473-K

Air control head: twelve-bore version

Air control head: low-pressure

Atomizing air

pressure

Air consumption

Air input of the spray

gun

Air consumption

1,0 bar

18,0 m

3

/h

1,0 bar

12,0 m

3

/h

2,0 bar

24,6 m

3

/h

2,0 bar

16,2 m

3

/h

3,0 bar

29,4 m

3

/h

3,0 bar

18,6 m

3

/h

4,0 bar

33,0 m

3

/h

4,0 bar

21,6 m

3

/h

5,0 bar

36,0 m

3

/h

4,5 bar

22,8 m

3

/h*

6,0 bar

39,0 m

3

/h

6,0 bar

26,4 m

3

/h

* The spraying pressure is 0.7 bar with an air input pressure of 4.5 bar.

Right to effect technical changes reserved.

Summary of Contents for PILOT WA 400

Page 3: ...Seite 6 23 Page 24 41 Page 42 59 Pagina 60 77 ...

Page 40: ......