6

7

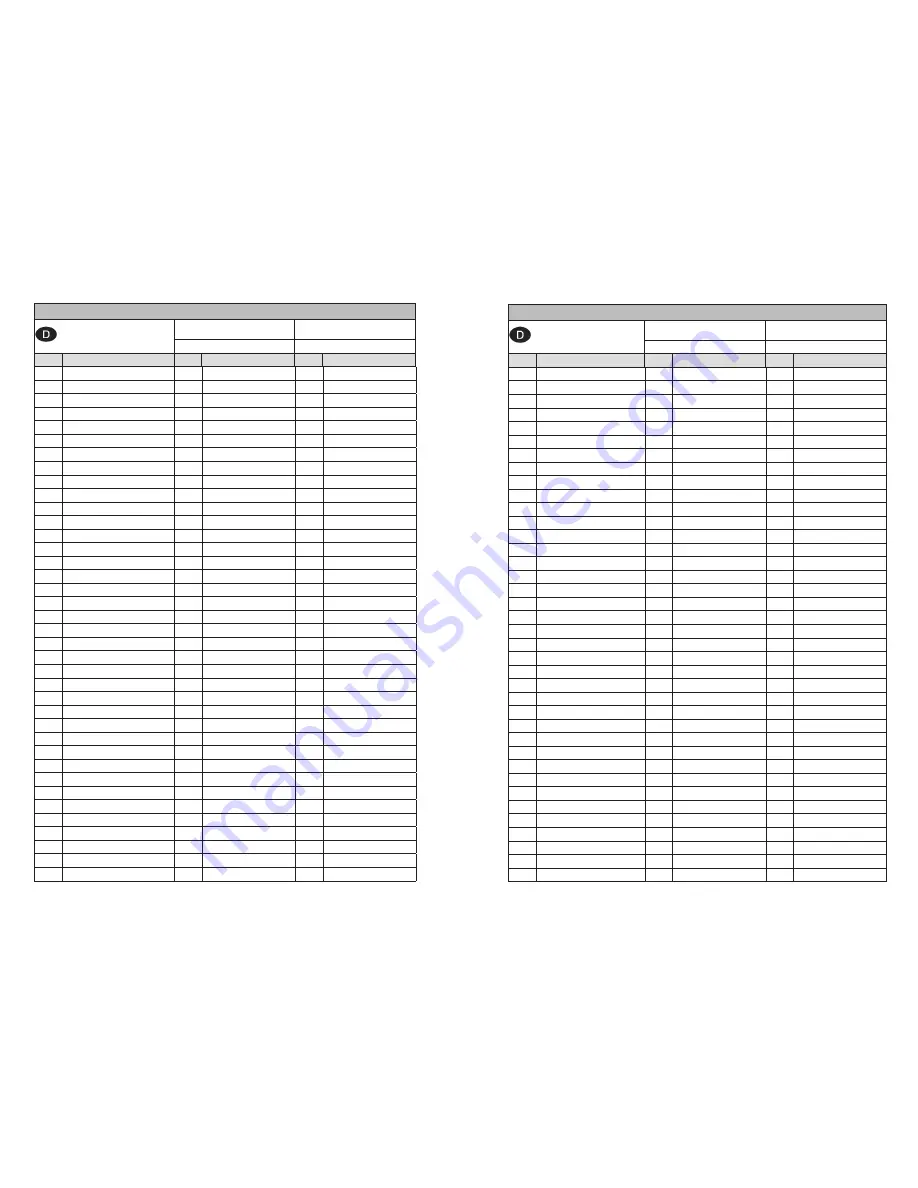

Spare Parts List:

WA 900

(with internal control)

WA 905

(with external control)

V 21 900

V 21 905

Pos.

Description

Pcs.

Part Number

Pcs.

Part Number

1

Air cap nut assy.

1

V 20 700 05 000

1

V 20 700 05 000

2

Air Cap

1

V 10 700 35 xx8*

1

V 10 700 35 xx8*

3

Material Nozzle

1

V 10 700 40 xx3*

1

V 10 700 40 xx3*

4

Air distribution ring

1

V 21 900 14 000

1

V 21 900 14 000

5

Hexagon socket screw

4

V 20 700 13 003

4

V 20 700 13 003

6

Cylinder Pin

1

V 20 350 05 001

1

V 20 350 05 001

7

Front Body

1

V 21 900 02 003

1

V 21 900 02 003

8

O-Ring

2

V 09 102 21 009

2

V 09 102 21 009

9

Needle Seal Packing

1

V 09 001 72 000

1

V 09 001 72 000

10

Washer

1

V 21 900 12 003

1

V 21 900 12 003

11

Packing Spring

1

V 20 510 12 003

1

V 20 510 12 003

12

Packing Screw

1

V 20 510 11 003

1

V 20 510 11 003

13

Pin for fixing air cap

1

V 20 700 02 303

1

V 20 700 02 303

14

Locking Spring

1

V 20 700 02 403

1

V 20 700 02 403

15

Screw

1

V 11 530 01 010

1

V 11 530 01 010

16

Plug

1

2325502

17

Sealing Screw

1

V 22 650 43 100

1

V 22 650 43 100

18

Retaining Ring

1

V 09 220 30 000

1

V 09 220 30 000

19

Piston Housing

1

V 21 900 01 000

1

V 21 905 01 000

20

Piston assy.

1

V 21 900 09 000

1

V 21 900 09 000

21

Material needle assy.

1

V 21 900 05 xx3*

1

V 21 900 05 xx3*

22

Piston Spring

1

V 20 606 11 100

1

V 20 606 11 100

23

Threaded bushing assy.

1

V 21 900 10 000

1

V 21 900 10 000

24

Needle Spring

1

V 20 510 29 103

1

V 20 510 29 103

25

Needle spring washer

1

V 21 900 11 000

1

V 21 900 11 000

26

Cap assy.

1

V 21 900 13 000

1

V 21 900 13 000

27

Pull rod assy.

1

V 20 510 34 000

1

V 20 510 34 000

28

Knobs

R + B

2

V 21 900 06 100

29

Threaded Bushing

2

V 10 170 10 100

30

Sealing Cone

2

V 20 810 11 005

31

O-Ring

2

V 09 102 02 007

32

Stuffing Gland

2

V 10 302 02 000

33

RD-regulation

1

V 21 900 06 000

34

BR-regulation

1

V 21 900 07 000

35

Counter sunk screw

2

V 10 170 25 003

36

O-Ring

1

V 09 103 64 009

1

V 09 103 64 009

37

Locking pin

1

V 21 900 08 000

1

V 21 900 08 000

38

Head screw

2

V 20 810 14 203

2

V 20 810 14 203

Spare Parts List:

WA 920 HVLP

(Internal Control)

WA 925 HVLP

(External Control)

V 21 920

V 21 925

Pos.

Bezeichnung

Stck.

Artikelnummer

Stck.

Artikelnummer

1

Air cap nut assy.

1

V 20 700 05 000

1

V 20 700 05 000

2

Air Cap

1

V 10 700 37 xxx*

1

V 10 700 37 xxx*

3

Material Nozzle

1

V 10 700 40 xx3*

1

V 10 700 40 xx3*

4

Air Distribution Ring

1

V 21 900 14 100

1

V 21 900 14 100

5

Hexagon Socket Screw

4

V 20 700 13 003

4

V 20 700 13 003

6

Cylinder Pin

1

V 20 350 05 001

1

V 20 350 05 001

7

Front Body

1

V 21 900 02 003

1

V 21 900 02 003

8

O-Ring

2

V 09 102 21 009

2

V 09 102 21 009

9

Needle Seal Packing

1

V 09 001 72 000

1

V 09 001 72 000

10

Washer

1

V 21 900 12 003

1

V 21 900 12 003

11

Packing Spring

1

V 20 510 12 003

1

V 20 510 12 003

12

Packing Screw

1

V 20 510 11 003

1

V 20 510 11 003

13

Pin for fixing air cap

1

V 20 700 02 303

1

V 20 700 02 303

14

Locking Spring

1

V 20 700 02 403

1

V 20 700 02 403

15

Screw

1

V 11 530 01 010

1

V 11 530 01 010

16

Plug

1

2325502

17

Sealing Screw

1

V 22 650 43 100

1

V 22 650 43 100

18

Retaining Ring

1

V 09 220 30 000

1

V 09 220 30 000

19

Piston Housing

1

V 21 900 01 000

1

V 21 905 01 000

20

Piston assy.

1

V 21 900 09 000

1

V 21 900 09 000

21

Material Needle assy.

1

V 21 900 05 xx3*

1

V 21 900 05 xx3*

22

Piston Spring

1

V 20 606 11 100

1

V 20 606 11 100

23

Threaded Bushing assy.

1

V 21 900 10 000

1

V 21 900 10 000

24

Needle Spring

1

V 20 510 29 103

1

V 20 510 29 103

25

Needle Spring Washer

1

V 21 900 11 000

1

V 21 900 11 000

26

Cap assy.

1

V 21 900 13 000

1

V 21 900 13 000

27

Pull Rod assy.

1

V 20 510 34 000

1

V 20 510 34 000

28

Knobs

R+B

2

V 21 900 06 100

29

Threaded Bushing

2

V 10 170 10 100

30

Sealing Cone

2

V 20 810 11 005

31

O-Ring

2

V 09 102 02 007

32

Stuffing Gland

2

V 10 302 02 000

33

RD-

Regulation

1

V 21 900 06 000

34

BR-Reg

ulation

1

V 21 900 07 000

35

Counter Sunk Screw

2

V 10 170 25 003

36

O-Ring

1

V 09 103 64 009

1

V 09 103 64 009

37

Locking Pin

1

V 21 900 08 000

1

V 21 900 08 000

38

Head Screw

2

V 20 810 14 203

2

V 20 810 14 203

Summary of Contents for PILOT WA 900

Page 14: ......