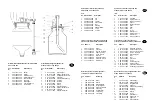

PILOT XIII-N: Gravity Feed Cup

1. Connect the air hose to the air pipe (clean compressed air) or to an air purifier

and the air inlet of the spray gun (Item 30).

2. Fill the gravity feed cup with screened material.

3. Close the gravity feed cup.

4. If necessary, connect the air hose of the gravity feed cup to the gun body using the

L-joint (Item 8).

5. Switch on the pneumatic system. The spray gun is now ready for operation.

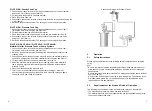

PILOT XIII-N: Pressure Feed Cup

1. Connect the air hose to the air pipe (clean compressed air) or to an air puri -

fier and the air inlet of the spray gun (Item 30).

2. Fill the pressure feed cup with screened material.

3. Close the pressure feed cup and screw it onto the gun attachment (Item 5).

4. If necessary, connect the air hose of the pressure feed cup to the gun body

using the L-joint (Item 13).

5. Switch on the pneumatic system. The spray gun is now ready for operation.

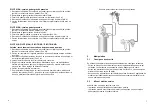

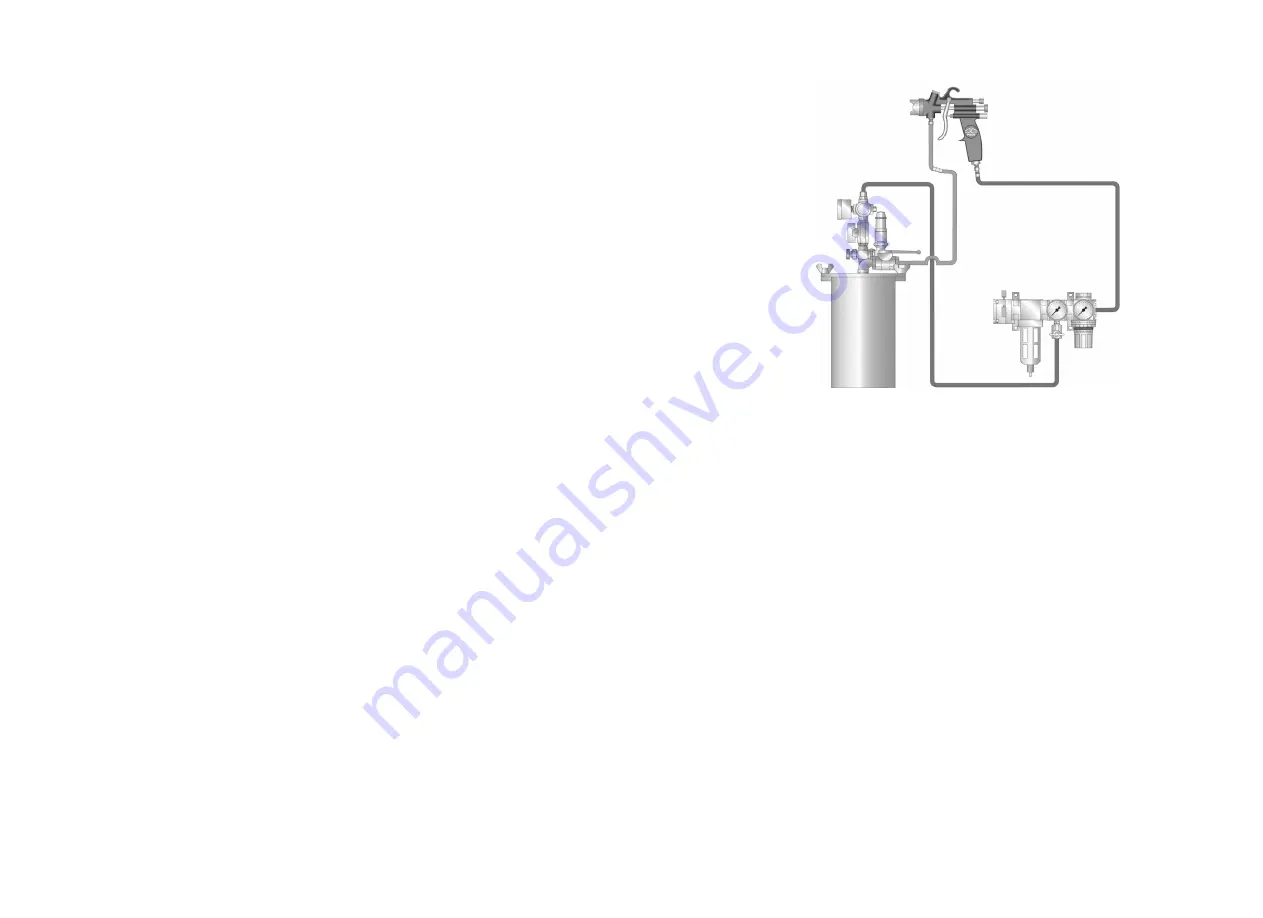

PILOT XIII /PILOT XIII-N / PILOT XIII-D / PILOT XIII-HD:

Material Inlet for Pressure Tanks or Pump Systems

1. Connect the air hose to the air pipe (clean compressed air) or to an air puri -

fier and the air inlet of the spray gun (Item 30).

2. Switch on the pneumatic system and adjust the atomising air pressure at the

reducing valve.

3. Connect the material feed hose to the pressure tank or the material pressure

control of a pump system and to the material inlet of the spray gun (Item 5).

4. Fill the material pressure tank with material and close the lid.

5. Adjust the desired material pressure at the reducing valve. If the material is

fed in via pump systems, the material pressure is adjusted at the material

pressure control.

6. Open the material tap at the pressure tank.

7. To let the air in the material hose escape, actuate the trigger (Item 33),

until a uniform jet emerges from the nozzle. Now close the spray gun again.

The spray gun is now ready for operation.

5

Operation

5.1

Safety Instructions

Please pay special attention to the following safety instructions when using the

spray

gun!

• Be sure to wear the required respiratory protection masks and protective over-

alls whenever you are operating the spray gun. Airborne particles represent a

health hazard.

• Be sure to wear suitable ear protection. The spray gun produces sound levels of

approx. 85 dB (A).

• No open fires, naked lights or smoking in the working area. The spraying of rea-

dily inflammable media (e.g. varnish, adhesives etc.) is accompanied by an

increased risk of fire and explosion.

5.2

Requirements at the Start and Finish of Operation

The following requirements must be met before the spray gun is operated:

• The atomising air pressure must be available at the gun

• The material pressure must be available at the gun (not applicable with gravity

feed cups, pressure feed cups).

6

7

Connection Diagram for Pressure Tanks