23

22

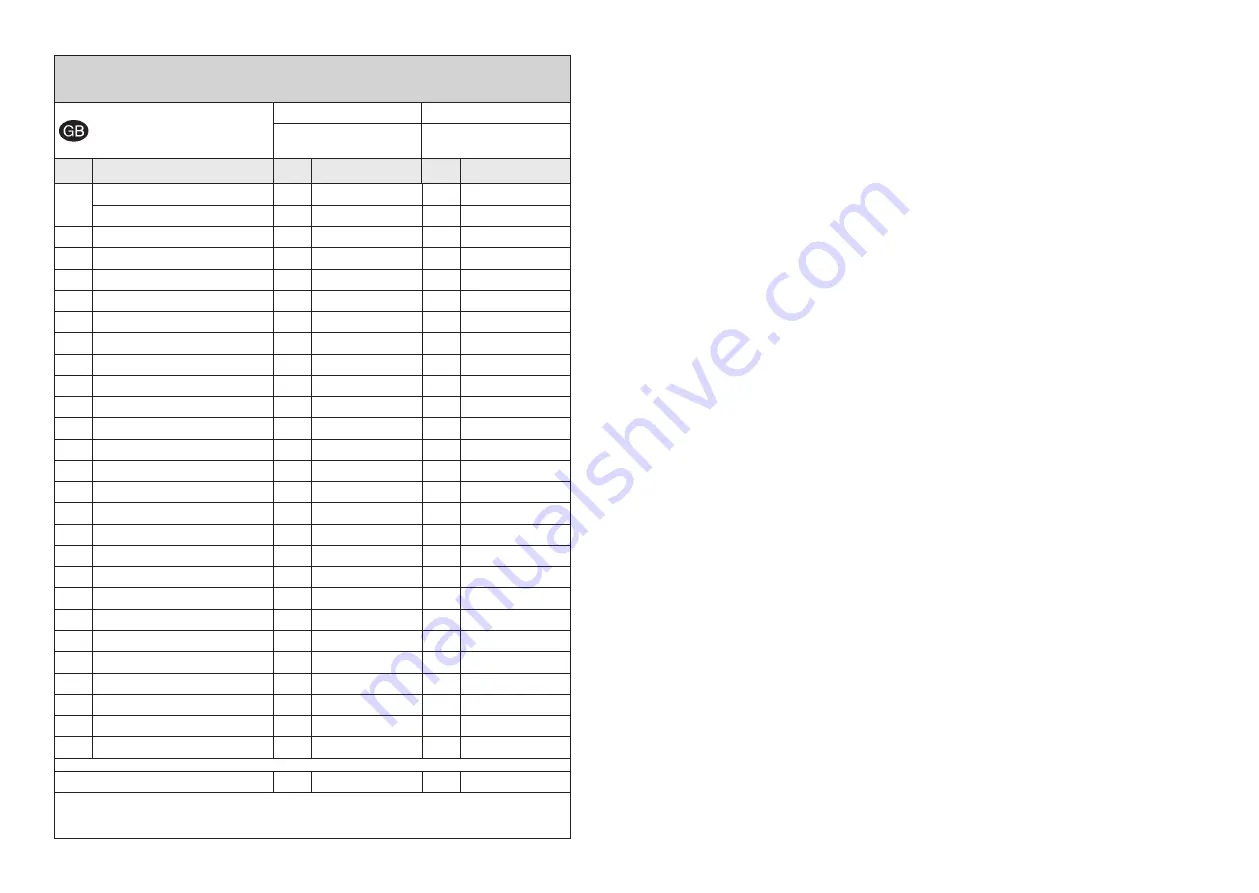

Listing of Replacement Parts PILOT WA 30

PILOT WA 30

PILOT WA 30

V 20 900 00 000

(350 bar)

V 20 901 00 000

(Dosing valve)

Item

Description

Qty.

Art. N°

Qty.

Art. N°

1

Gun Body Aluminium

1

V 20 900 01 000

1

V 20 900 01 000

Gun Body Stainless steel

1

V 20 902 01 003

1

V 20 902 01 003

2

Seal

1

V 09 002 12 000

1

V 09 002 12 000

3

Barrel Nipple

1

V 20 900 11 003

1

V 20 900 11 003

4

Needle Seal Packing (compl.)

1

V 20 900 13 000

1

V 20 900 13 000

5

Needle Packing Gland

1

V 20 900 03 003

1

V 20 900 03 003

6

Material Control Needle

1

V 20 900 06 003

1

V 20 900 06 003

7

„V“-Packing Ring

1

V 09 220 20 000

1

V 09 220 20 000

8

O-Ring

1

V 09 103 17 002

1

V 09 103 17 002

9

Piston

1

V 20 900 07 004

1

V 20 900 07 004

10

Serrated Lock Washer

1

V 20 900 14 001

1

V 20 900 14 001

11

Hexagonal Nut

1

V 20 900 15 003

1

V 20 900 15 003

12

Piston Spring

1

V 20 900 22 000

1

V 20 900 22 000

13

Spring Retaining Bush

1

V 20 900 10 000

1

V 20 900 10 000

14

Sleeve Nut

1

V 01 101 03 000

1

V 01 101 03 000

15

Sleeve Nut

1

V 20 900 05 001

1

V 20 902 02 003

16

Airless Spray Tip (to choice)

1

17

Seal

1

G 16 286 30 000

18

Needle Seat

1

V 20 900 04 002

19

O-Ring

1

V 09 103 14 001

20

Threaded Bush

1

V 20 900 02 003

21

O-Ring

1

V 09 103 16 001

22

Seal

1

V 09 002 13 000

1

V 09 002 13 000

23

Screw Plug

1

V 20 540 40 005

1

V 20 540 40 005

24

Quick-Release Fitting with Seal

1

V 66 100 02 027

1

V 66 100 02 027

25

Needle Seal

1

V 20 901 04 002

26

Needle

1

V 20 901 06 003

Repair kit:

1

V 16 130 00 010

1

V 16 130 00 015

We recommend that the bold-faced replacement parts (i.e. wearing parts) are held on

stock !

1 General

1.1

Identification of Model Version

Type Series:

PILOT WA 30

Model:

Automatic Airless Spray Gun

Art. No. V 20 900 00 000

Model:

Dosing valve

Art. No. V 20 901 00 000

Manufacturer:

WALTHER Spritz- und Lackiersysteme GmbH

Kärntner Strasse 18-30

D-42327 Wuppertal

Germany

TEL: 0202/ 787-0

FAX: 0202/ 787-2217

1.2

Normal Use

The automatic Airless spray gun Model PILOT WA 30 (Art. No. V 20 900 00 000) is

exclusively designed for use with all Airless-sprayable material types and grades

such as, for example:

•

paints and lacquers

•

greases, oils and corrosion preventives

•

adhesive compounds

•

ceramic glazes

•

acidiferous media (stainless specialty version only) and

•

pickling solutions

If your specific material is not listed above, please contact WALTHER Spritz- und

Lackiersysteme GmbH, Wuppertal for further and detailed information.

Please note that sprayable material may only be applied to workpieces and/or similar

items.

The temperature of the spraying material shall never exceed 80° C.

The dosing valve (V 2090100000) is provided for the dosing of liquids. A spraying

finction does nor exist.

The term "normal use" also implies that any and all safety warnings, operational

handling details, etc., as contained in these Operating Instructions, are carefully

read, understood and duly complied with.

This equipment complies with the explosion protection requirements of Directive

2014/34/EU (ATEX) for the explosion group, equipment category and temperature

class indicated on the type plate. When using the equipment, the requirements

specified in these Operating Instructions must be observed at all times.

The technical data indicated on the equipment rating plates and the specifications in

the chapter "Technical Data" must be complied with at all times and must not be

exceeded. An overloading of the equipment must be ruled out.

The equipment may be used in potentially explosive atmospheres only with the

authorisation of the relevant supervisory authority.

The relevant supervisory authority or the operator of the equipment are

responsible for determining the explosion hazard (zone classification).