27

26

5.1

Changing the Air Cap

1. Unscrew the air cap nut.

2. Remove the air cap (Pos.1).

5.2

Changing the Material Nozzle

1. Unscrew the air cap nut.

2. Remove the air cap.

3. Unscrew the material nozzle (Pos.2) from the spray gun head.

Installation takes place in reverse order.

5.3

Changing the Material Needle

1. Unscrew the threaded rod (Pos. 22).

2. Unscrew the air cap (Pos. 21).

3. Remove the needle spring (Pos 20).

4. Unscrew the threaded ring (Pos. 19).

5. Withdraw the piston (Pos. 11) together with the material needle (Pos. 17).

6. Unscrew the material needle from the piston.

7. The distance between the tip of the material needle and the piston should be

set at 79,0 mm.

Installation takes place in reverse order.

5.4

Changing the Needle Seal

1. Unscrew the front part from the piston casing.

2. Remove the seal.

3. Remove the complete needle packing using a strong wire with a hook at its

end.

4. Lubricate the new needle seal packing..

Installation takes place in reverse order.

4.3

Changing the Spray Pattern

•

Round-fan or wide-fan air caps are available.

•

The fan width can be varied by changing the atomising air.

•

The material flow rate is determined by the material pressure and the diameter

of the material nozzle.

4.4

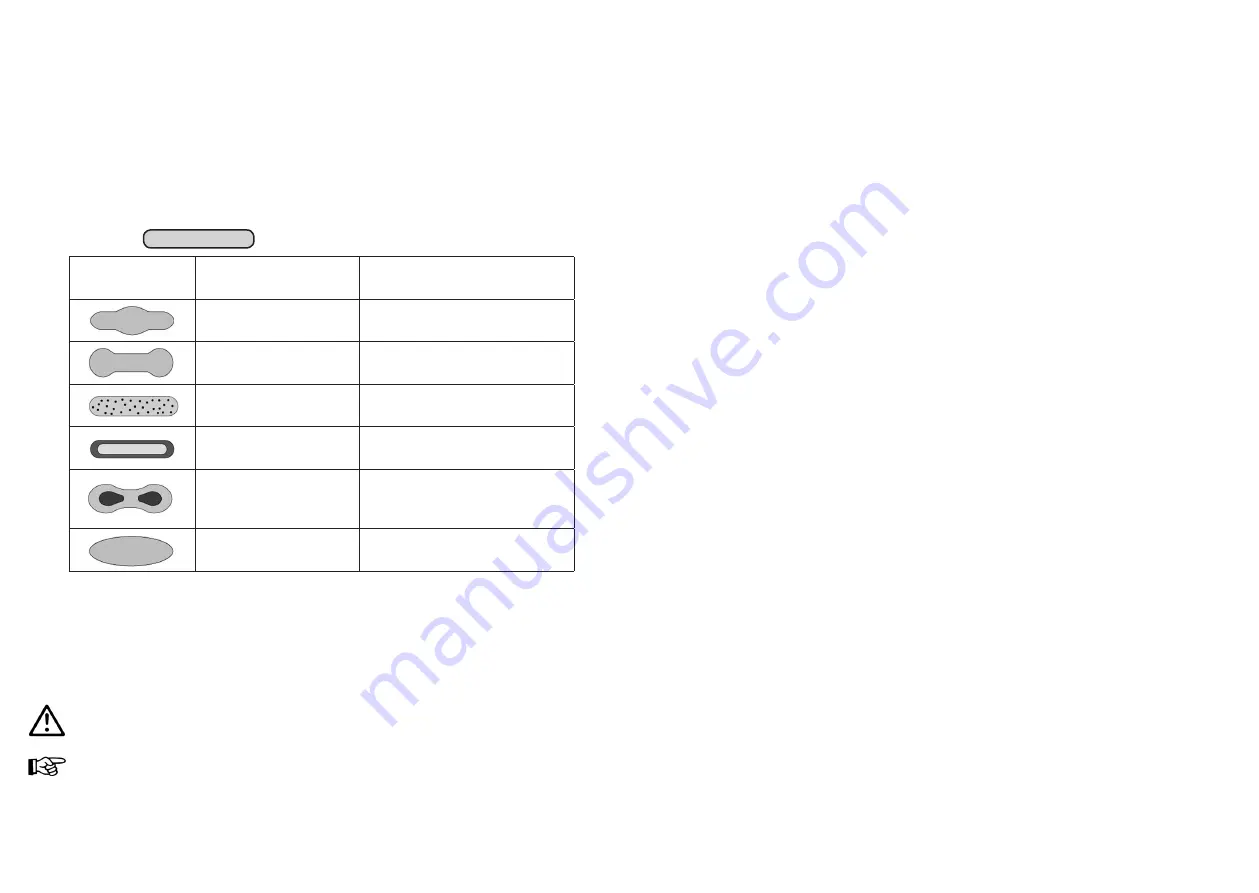

Correction of Spray Pattern Imperfections

The following table shows how to correct a defective spray pattern.

Spray pattern

test

Fault

Necessary adjustment

Swollen centre

• Spray jet should be flatter

Swollen ends

• Spray jet should be rounder

Coarse pearl effect

• Increase atomising air pressure

Unduly thin paint layer in

centre

• Decrease atomising air pressu-

re

Split centre

• Increase nozzle diameter

• Reduce atomising air pressure

• Increase material pressure

Very spherical

• Decrease material pressure

• Increase atomising air pressure

5

Re-tooling the Spray Gun

The combination of air cap, material nozzle and needle for a certain spraying

material forms a specially matched unit - the nozzle assembly.

Always exchange the complete nozzle assembly in order to maintain the desired

spray pattern quality.

Warning

Air and material inputs must be shut off prior to re-tooling - risk of injury.

Note

Please refer to the exploded view at the beginning of this manual to perform the steps

detailed below.

Desired Spray Pattern

Summary of Contents for WA 600

Page 2: ...Seite 6 17 Page 18 29...