34

35

5.5

Retooling of Spray Gun

Combinations of air cap, material needle, designed to match specific

spraying media types and grades, form a unit - namely the nozzle insert assembly,

which must always be interchanged as a complete assembly to maintain the desi-

red spray- finish quality standard.

Warning

Prior to retooling: make sure that the spray gun is in unpressurized condition, i.e.

all air and material inputs must be shut off - if not, imminent Risk of Injury.

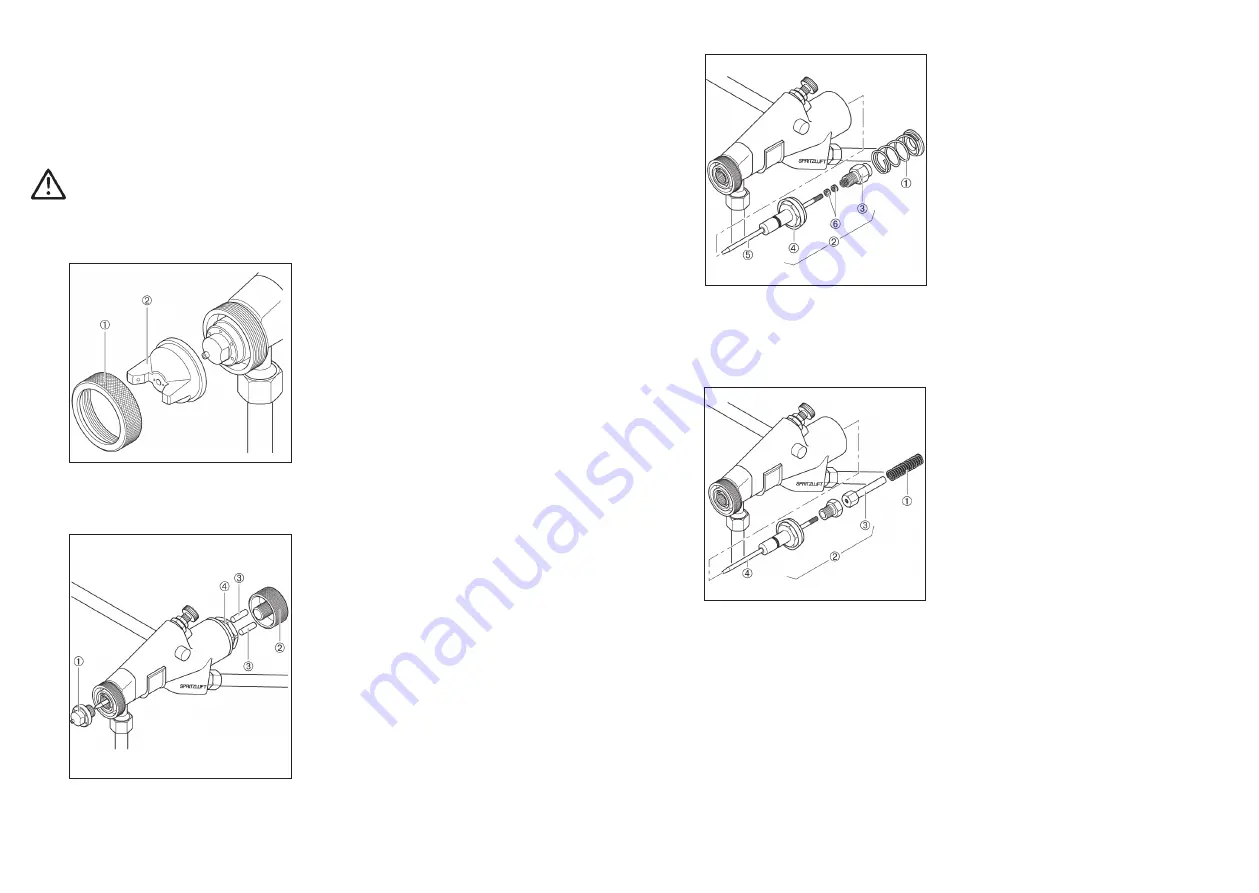

Replacement of Air Cap

Replacement of Material Nozzle and Needle

WA XV / WA XV-HVLP:

1. Unscrew the knurled air cap retaining

ring

.

2. Pull the air cap

off the gun front

attachment.

3. Position the required air cap an the gun

front attachment.

4. Screw the air cap retaining ring

onto

the gun front attachment.

1. Remove all Pressures from the gun (see

5.2 Starting / Stopping Requirements

).

2. Remove the air control head (see

5.5

Replacement of Air Cap

).

3. Unscrew the material nozzle

from the

gun front attachment (use a Size 12 mm

wrench).

4. Unscrew the material Input regulating

screw

.

5. Pull the two spring pins

off.

6. Unscrew the spring retaining bush

(use a Size 27 mm wrench).

7. Remove the compression spring

from

the gun body.

Installation of the new nozzle insert assembly and of the remaining parts in reverse

order.

WA XV needle-pull / WA XV-HVLP:

Installation of the new nozzle insert assembly and of the remaining parts in reverse

order.

8. Remove the piston

very carefully from

the gun body (use a suitable pair of pliers).

9. Remove the piston end nute from the con-

trol piston

(use Size 13 mm and 22 mm

wrenches). The material needle

is now

freely accessible and can be pulled out.

10. Unscrew the two needle retaining nuts

.

1. Remove all pressures from the gun (see

5.2 Starting / Stopping Requirements

).

2. Remove the air control head (see

5.5

Replacement of Air Cap)

.

3. Unscrew the material nozzle from the gun

front attachment (12 mm wrench).

4. Remove the cap screw and pull the was-

her off.

5. Remove the material input regulating

screw.

6. Pull the needle spring

out.

7. Pull the stop piston

plus material need-

le

out.

8. Unscrew the material needle

from the

stop pin

.