38

39

7

Repairs / Replacements

Warning

Prior to any repairs/replacements: Make sure that the spray gun is in unpressurised

condition, i.e. all air and material inputs must be shut off - if not, imminent Risk of Injury.

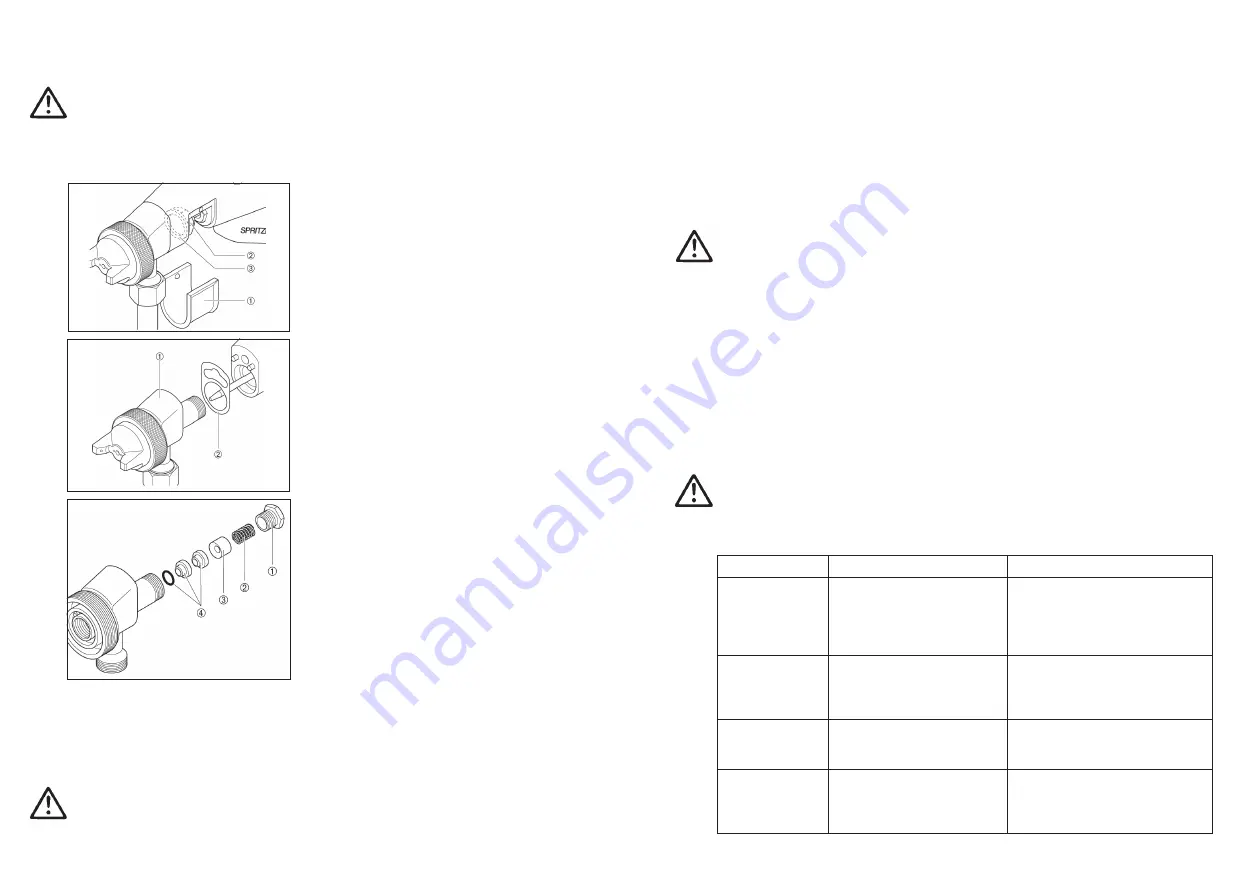

7.1

Replacement of defective Needle Seal Packings

10. Lubricate the new needle seal packing with a non-acidic, non-resinogenic

grease type / grade.

11. Install the new needle seal packing in the gun body.

Installation of the remaining parts in reverse order.

Caution

Never reinstall a used needle seal packing as, otherwise, the functional sealing

reliability of the spray gun will suffer.

1. Remove all pressures from the gun -see

5.2 Starting / Stopping Requirements

.

2. Pull the white protective cover

off the

gun body.

3. Unscrew the hex. nut

with a Size 17 mm

wrench.

4. Pull the "USIT" ring

off.

5. Pull the gun front attachment

carefully

off the gun body.

6. Remove the gasket

- and replace same

if damaged.

7. Unscrew the packing seal

with a Size

11 mm from the gun front attachment.

8. Remove the compression spring

(re-

place if damaged) and the counter bush

from the threaded socket.

9. Remove the needle seal packing

from

its seat - use a strong wire with one end

bent to form a small hook.

7.2

Replacement of Nozzles, Needles, Springs and Seals

For replacement of any of the following parts dismantle the spray gun in accor-

dance with

5.5 Replacement of Material Nozzle and Needle

:

•

Material Nozzle

•

Piston Spring

•

Material Needle*

•

Needle Spring*

•

Piston Sealing Collar*

•

Piston O-Ring*

Caution

Parts marked * must be lubricated with a non-acidic, non-resinogenic grease type /

grade prior to installation.

WALTHER Repair kits are also available for WA XV, WA XV needle-pull and WA

XV-HVLP spray guns. Wearing parts are also shown (in boldface) in the Listing of

Replacement Parts.

Repair kit-material side:

WA XV:

Art. No.: V 16 115 03 . . 3

WA XV needle pull:

Art. No.: V 16 116 03 . . 3

WA XV-HVLP:

Art. No.: V 16 117 03 . . 3

8

Troubleshooting and Corrective Action

Warning

Prior to any servicing and repair work: Make sure that the spray gun is in unpressuri-

zed condition, i.e. all air and material inputs must be shut off - if not, imminent Risk of

Injury.

Fault

Cause

Remedy

Gun is dripping

Material nozzle or needle fou-

led or damaged

Packing gland too tight

Remove see 5.5 Material Nozzle or

Needle and clean or replace

Loosen packing gland slightly use a

Size 11 wrench

Gun fails to open

Control air pressure too low

Increase control air pressure to

max. 8 bar (see operating

Instructions of plant systems manuf-

acturer)

Spray jet pulsa-

ting or unsteady

Level in material tank too low

Top-up material level (see operating

Instructions of plant systems manuf-

acturer)

Material leaks

from packing

gland

Needle seal packing leaks

Packing gland to loose

Replace see 7.1 Needle Seal pak-

king

Tighten packing gland slightly use a

Size 11 mm wrench