Rev. 1.5

Operating Manual Table-top Greasing Device TBV-H-0x-xx

Page 7 of 35

Walther Systemtechnik GmbH

–

D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de

–

info@walther-2000.de

3 Transport

3.1 Packaging

The type of packaging depends on the individual mode of shipping. If not separately contracted, the

packaging is in accordance with the rules and regulations of Walther Systemtechnik GmbH. This rule is in

accordance with the Federal Association for Packaging HPE.

3.2 Tasks before Transport

The following has to be done before transport:

Disconnect all power lines.

The actual transport of the device and its individual parts requires special care in order to prevent damages

from external forceful impact or careless on- and off-loading. Depending on the mode of transportation,

suitable transport and load securing has to be selected. The device will be aligned and leveled by

appropriate fastening elements.

4 Description of Function

Tabletop greasing unit for exchangeable application tools for the volumetric dosing of lubricants.

4.1 Purpose of the Device

The special construction of our dosing valves enables the supply of a specific lubricant in a specific amount

at a specific time and location. The dosing valves are also suitable for use with oil.

CAUTION

The use of other media can cause functional failures, damages or even the destruction of the

device.

IMPORTANT

Use the engraved data and the information from the type label for ordering spare parts or for

technical support.

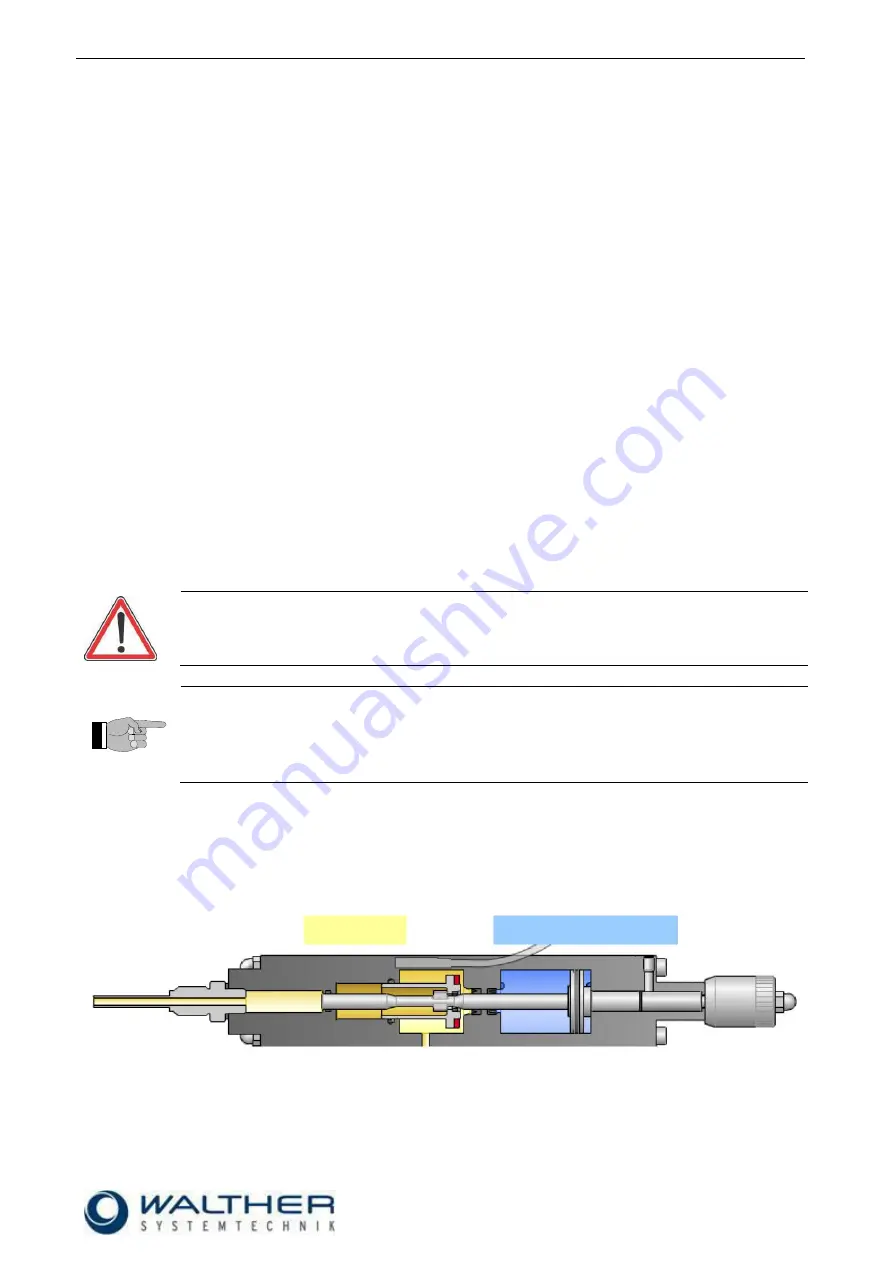

4.2 Function of Device

The pneumatic part of the dosing valve is controlled by a 5/2-way valve installed in the housing. Pressing the

trigger initiates ejection of the dosed medium. The output pressure depends on the lubricant feed pressure

(medium). The pneumatic system is separated from the grease chamber.

Grease

Pneumatics