Rev. 1.4

Assembly Instructions

– Full-Jet Valve VMS-02

Page 11 of 19

Walther Systemtechnik GmbH

– D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de

– info@walther-2000.de

7.5 Inserting Gaskets and O-Rings

IMPORTANT

Gaskets and sealing kits can be damaged. Do not use any sharp-edged metal tools for remov-

ing or inserting gaskets!

If a complete sealing screw (pos. 4.0) with an inserted gasket set (pos. 3.0) is not available as a

replacement, the old gaskets must be removed and replaced with new ones. In order to do so, the sealing

screw must be thoroughly cleaned so that no particles of the previous spraying fluid impair the installation of

the new gaskets. The O-ring seats should be lightly greased with a lubricant (technical Vaseline). First insert

O-ring (pos. 4.2) into the rear hole of the sealing screw until it reaches the end. Then insert O-ring (pos. 3.1)

into the outermost groove. Insert the special form gasket (pos. 3.3) into the front seat. Since this form gasket

is not symmetrical, the side with the larger outer diameter must be inserted facing forwards, i.e. it must point

in the direction of the nozzle after the complete sealing screw has been installed. Slightly grease the sealing

screw (pos. 4.0) and insert it back into the valve body (pos. 2.0). Use a screwdriver to carefully push it

through the mounting thread together with the outer O-ring (pos. 3.1) without twisting it. Then screw the

sealing screw into the thread (gently tighten).

Do not use any metallic or sharp-edged aids or tools when you insert the O-rings and the special form

gasket. Despite all its outstanding sealing qualities, the special form gasket is a sensitive precision

component, which cannot tolerate impacts or pressure.

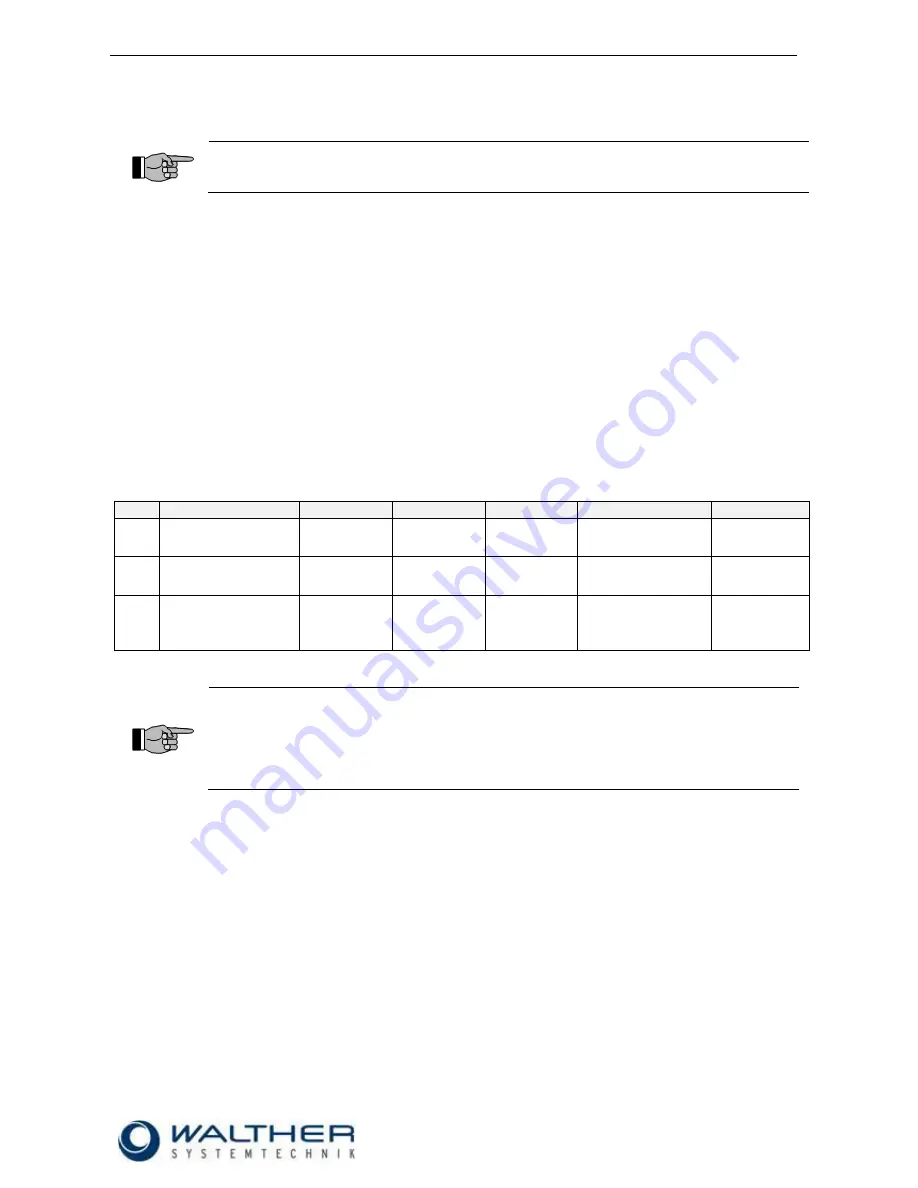

7.6 Routine Tasks

No.

Description

Cleaning

Lubricating

Inspecting

Additional tasks

Frequency

1.

connections

(tightness)

X

monthly

2.

nozzle

X

X

exchange if

damaged

monthly

3.

complete valve

X

check for wear

after 10 mio.

switching

operations

7.7 Spare Parts

IMPORTANT

Only use original spare parts from the manufacturer!

Wrong or defective spare parts from other manufacturers can damage the device. If other

than original spare parts of the manufacturer will be used, all obligations from the manufac-

turer or his sales partners, such as guarantees, service contracts etc will be

forfeited

without

further notice.

7.8 Customer Service / Support

Walther Systemtechnik GmbH

Hockenheimer Straße 3

D-76726 Germersheim

Deutschland

Telefon

++49(0)7274-7022-0

Telefax

++49(0)7274-7022-91

info@walther-2000.de

Internet

www.walther-2000.de