13

English

Please observe the points below for trouble-free

installation and commissioning.

3.1

Prerequisites

• At least two Wallboxes with local load

management.

• At least one Wallbox and an external control

system with external load management.

• Maximum of 16 Wallboxes

• One hybrid/electric vehicle per Wallbox.

• Energy supply at least 6 A per Wallbox (in case of

overloading, ongoing charging processes will be

completed first).

i

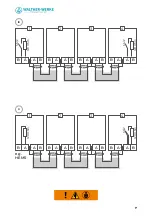

To avoid single-phase load peaks, connect the

devices with an alternating phase sequence.

• First Wallbox: L1, L2, L3.

• Second Wallbox: L2, L3, L1.

• Third Wallbox: L3, L1, L2.

• Fourth Wallbox: L1, L2, L3 again, etc.

3.2

Bus topology

Prerequisites:

• Bus system: RS485 fieldbus

• Protocol: Modbus RTU

• The leader distributes the total current in the

system.

• A charging current (default: 6 A) is configured for

each Wallbox. Set the required charging current.

• The follower Wallboxes revert to standby state

when not in use.

• Communication between the follower Wallbox

and leader Wallbox is required in order to start

the charging process.

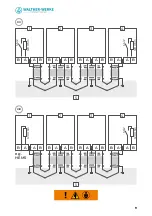

Local load management:

• One Wallbox as the leader and at least one or

up to 15 Wallboxes as followers.

• The physical position of the Wallbox (leader)

is freely selectable.

External load management:

• External control system (e.g. HEMS) which is

configured as the leader and at least one or

up to 16 Wallboxes as followers.

3.3

Check-list for local load

management

• Wire the power supply and the bus system

so as to avoid single-phase load peaks.

• Select the leader Wallbox.

• Set the number of follower Wallboxes in the

leader Wallbox.

• Set the maximum system current in the leader

Wallbox.

• Set the maximum and minimum individual

charging currents in each Wallbox.

• Set the bus ID in each follower Wallbox.

• Activate the bus terminating resistor in the first

and last Wallboxes.

• Configure the optional blocking function in the

leader Wallbox.

3.4

Check-list for external load

management

• Wire the power supply and the bus system so as

to avoid single-phase load peaks.

• Configure the external control system (following

the manufacturer’s instructions).

• Set each Wallbox as a follower Wallbox.

• Set the bus ID in each Wallbox.

• Set the maximum and minimum individual

charging currents in each Wallbox.

• Activate the bus terminating resistor in the

external control system and the last Wallbox.

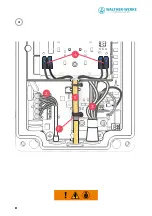

4. Configuration of the Wallboxes

The individual Wallboxes must be pre-configured

using rotary switches and micro switches to operate

the integrated network of Wallboxes

. All

rotary switches and micro switches are initially set

to OFF. The configuration differs in some cases,

depending on the local or external load manage-

ment mode.

Mode-independent switch functions:

S1: rotary switch S1 is used to set the maximum

charging current of 6 A to 16 A per Wallbox

S3: configuration of minimum charging current

S6: bus terminating resistor On/Off

Switch functions in local load management mode:

S2: setting of maximum system current (only in

leader Wallbox)

S4: in leader Wallbox: setting of the number of

followers

S4: In follower Wallbox: setting of the respective bus ID

S5: setting of leader or follower, front illumination

and blocking

Switch functions in external load management mode:

S2: configuration of bus ID 16

S4: configuration of bus IDs 1 to 15

S5: setting of leader or follower, front illumination