Rev. 1.0

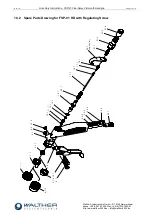

Assembly Instructions - FSP-01 Fine-Spray Pistol with Handgrip

Page 11 of 19

Walther Systemtechnik GmbH

– D 76726 Germersheim

phone: +49 (0)7274-7022-0 fax: +49 (0)7274-7022-91

http://www.walther-2000.de

– info@walther-2000.de

8.5 Spare Parts

IMPORTANT

Only use original spare parts from the manufacturer!

Wrong or defective spare parts from other manufacturers can damage the device. If

other than original spare parts of the manufacturer will be used, all obligations from the

manufacturer or his sales partners, such as guarantees, service contracts etc will be

forfeited

without further notice.

8.6 Customer Service / Support

Walther Systemtechnik GmbH

Hockenheimer Straße 3

D-76726 Germersheim

Germany

phone

++49(0)7274-7022-0

fax

++49(0)7274-7022-91

internet

9 Troubleshooting

9.1 General Information

IMPORTANT

First check all supply lines for connectivity and serviceability.

In case of serious problems that cannot be resolved, please contact the Walther Systemtechnik GmbH cus-

tomer service.

9.2 Cases of Failure

Drops form on the trigger

The needle gasket (10.1) is either worn or loose and must slightly be retightened. For that purpose remove

needle/valve cartridge (see section 6.4). Then unscrew screw (12.2) and take out needle driver (12.1). Using

a small screw driver turn stuffing box (11.1) gently clockwise and try if needle is sliding smoothly again within

the tightening gasket.

Drops form on the nozzle

Either the needle or the nozzle is worn and should be replaced. Or needle is not closed properly because of

particle residues within nozzle. Clean the needle/valve cartridge with solvent (see section 6.2).

Uneven and not steady spray jet

Make sure that nozzle is screwed in tight. Other reason could also be dirt residue within air cap. Clean air

cap with solvent.

Air is blowing constantly although trigger is released

O-Ring (13.1) and/or washer (14.1) are worn and must be exchanged. Or needle nuts are not counter-

screwed in correct position (see section 6.4).