Rev. 1.0

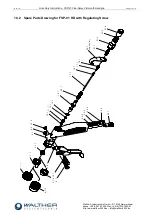

Assembly Instructions - FSP-01 Fine-Spray Pistol with Handgrip

Page 7 of 19

Walther Systemtechnik GmbH

– D 76726 Germersheim

phone: +49 (0)7274-7022-0 fax: +49 (0)7274-7022-91

http://www.walther-2000.de

– info@walther-2000.de

4.2 Technical data

KLS and HVLP

Weight [g]

approx. 240

Control air pressure [bar]

max. 6

Material pressure [bar]

max. 4

With Adjusting Screw

Weight [g]

approx. 270

Air consumption [l/min]

approx. 90 (at 3 bar and 0.5mm nozzle)

Control air pressure [bar]

max. 6

Material pressure [bar]

max. 50

5 Initial Start-up

5.1 Installation

Connect hoses

Material:

spray medium to pistol connection “M” (26.1)

Air:

spray a

ir to pistol connection “AIR” (26.0)

Set atomizing air pressure via reducing valve (not part of the spray gun).

Set material pressure via a second reducing valve (not part of the spray gun). The supply pressure

and the spray air pressure will determine the drop-size of the spray medium in the jet.

6 Operation

6.1 General Information

This device may only be operated if the safety-related equipment is permanently effective and not suspend-

ed during operation or altered in its intended effectiveness.

6.2 Operating Instructions

CAUTION

Never point the jet at people. The wearing of eye protection is strongly recommended.

The spraying process can create noise depending on the air and fluid pressures used.

Ear protection should be worn, if required.

WARNING

Danger caused by flammable, harmful fluid. Always follow the safety instructions on the

container or the safety data sheet for the fluid.