Rev. 1.0

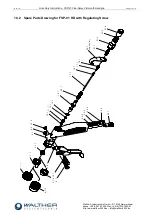

Assembly Instructions - FSP-01 Fine-Spray Pistol with Handgrip

Page 8 of 19

Walther Systemtechnik GmbH

– D 76726 Germersheim

phone: +49 (0)7274-7022-0 fax: +49 (0)7274-7022-91

http://www.walther-2000.de

– info@walther-2000.de

Activate releasing

trigger (19.1). Spray operation starts. You will notice that you receive so called “pre-air”

prior to opening fluid flow when pulling the trigger. When releasing the

trigger you still have “purging-air” after

needle has closed nozzle and fluid flow was stopped. This prevents that fluid forms drops instead of the de-

sired atomization.

IMPORTANT

After the spraying operation the pistol should be briefly blown free of any residues, in

order that the nozzle does not clog up and hamper the atomizing process.

Depending on the viscosity of the medium, the following nozzle bores are available: 0.2 ; 0.3 ; 0.5 ; 0.8 and

1.0 mm

(only one size of air cap is required for all standard nozzles).

The standard spray pistol is equipped with a flat-spray cap 3.1.1. A round-spray cap 3.1.2 can be used and

ordered as an accessory.

Flat-spray air caps can be individually positioned horizontally, vertically etc. by means of turning the air cap.

The spraying air must be controlled as such, that it is switched on before the needle opens and is switched

off after the nozzle has closed again (resulting in minimum maintenance work).

The valves can be controlled for intermittent or continuous use. According to the individual application, the

control air must be adjusted to the operating cycles and to the higher or lower material pressures. 30 tacts

per second can be reached under appropriate operating conditions (material pressure, control air pressure,

needle stroke, short conductions)

IMPORTANT

The spraying material amount can be adjusted to the individual requirements by turning

the regulating screw (24.1.0) (if provided):

Right turn: decrease in material amount

Left turn: increase in material amount

Nozzle and needle can be damaged by wrong handling. Only decrease the material

flow (by a right turn of the regulating knob) if material spills out. Do not turn the regulat-

ing knob further to the right after the nozzle is closed!

It is harmless to leave fluid in the valve during longer standstills, if system stays under pressure (no connec-

tion to outside air).