5.0 INSTALLATION AND FIXING

2

EXT.SBB-HFF.--.M.A.0219.EN Issue: A

02.19

23

SBB-HFF

5.1 Recommendations for installation

Danger - Warning

The installation operations have to be carried out by a technician specialized in such activities.

Provide appropriate safety measures and use suitable equipment to prevent risk of work accident to

persons involved in the operations and to those nearby.

Harness and handle the sections of the equipment concerned as described and shown in the “Unload

-

ing and lifting method” paragraph.

The FIBC UNLOADER must be installed with sufficient clearance around it to allow for normal assembly/disas

-

sembly, cleaning and maintenance operations.

In this manual, from here onwards “

setting the machine in safety conditions

” will indicate the following

operations:

- Make sure the machine is disconnected from all electric power supply sources.

- Make sure the machine is completely stopped

- Provide sufficient lighting around the machine operating area (the operators may be provided with electric

lamps if necessary).

- Wait for the powder mass inside to settle down completely, and then stop the machine.

Before carrying out any operation on the machine (maintenance or cleaning), the operators must use suitable

personal protection equipment:

- antistatic safety footwear (certified)

- antistatic protective clothing (certified)

- helmet

- antistatic, cut-proof gloves

- safety masks

In addition to these, use the safety devices specified in the safety chart of the product handled.

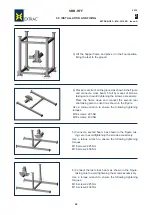

5.2 Positioning

To remove the packing, use a cutter or a pair of scissors to cut the heat-shrink nylon covering.

Take special care to avoid damaging parts of the machine and/or scratch the paint with the blade.

It is recommended to use a hammer to remove the packaging of the crate that protects the machine.

The FIBCs require certain operations for completing assembly before starting operation, in particular:

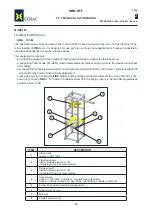

Summary of Contents for SBB 125 C

Page 57: ......