6.0 INFORMATION REGARDING USE

2

EXT.SBB-HFF.--.M.A.0219.EN Issue: A

02.19

42

SBB-HFF

6.1 Production Start-up

PRELIMINARY OPERATIONS PRIOR TO START-UP

Before starting up the plant, it is essential to carry out a series of checks to prevent problems or risks.

Ascertain that all the equipment components are positioned and fixed correctly.

Carefully check all the connections, the rubber hoses and fixtures.

If pneumatic activators are provided, special attention must be paid to the compressed air connections.

Danger - Warning

1) It is recommended not to operate the motor vibrator when the machine is empty (not even in the test

phase) in order to avoid the overheating of said device, as well as to avoid the subsequent possible

and irreversible damaging thereof.

2) In order to ensure the proper operation of the machine, it is advisable to operate the motor vibra-

tor for periods not longer than 10-15 seconds per minute in order to avoid the compaction of the

product within the hopper; Please remember that it takes about 40-45 seconds for the masses to

completely stop.

3) For proper functioning of the FIBC unloader, the equipment downline must be capable of removing

all the product extracted from the FIBC.

4) The connection between the outlet spout of the FIBC Unloader and any other equipment positioned

downline must be made using a flexible connector to prevent vibrations of the hopper from being

transmitted to the equipment.

5) It is advisable to provide a butterfly valve or slide valve at the hopper outlet in order to prevent

outflow of product when the motovibrator stops operating.

START-UP - OPERATION

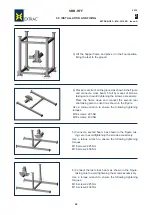

1)

Lift the fixing cross of the FIBC above the

FIBC by means of a forklift truck or a hoist,

and fix the slings to the hooks.

2)

Lift the cross on which the FIBC is hooked

by means of a forklift truck or hoist and in-

sert it in the supporting frame.

Summary of Contents for SBB 125 C

Page 57: ......