7.0 INFORMATION REGARDING MAINTENANCE

2

EXT.SBB-HFF.--.M.A.0219.EN Issue: A

02.19

48

SBB-HFF

Caution

All maintenance, lubrication and cleaning operations must be performed with the machine in safety

conditions.

For hazardous materials, suitable PPD (personal protection devices) must be used in accordance with the

safety chart of the powder handled.

Maintenance must be done only by qualified technicians.

Lift and handle all heavy parts using suitable lifting equipment.

Make sure that the parts or components are supported by suitable harnesses or hooks.

Ensure that there is no one standing in the area where the load is being lifted.

Remember that careful periodic maintenance and correct use are essential requirements for guaranteeing

high machine performance.

To ensure that the machine functions constantly and normally and to prevent the guarantee’s replacement

clauses being invalidated, we recommend that you always use original spare parts.

Maintenance of the vibrator motor must be carried out in accordance with the instructions given in the relevant

manual.

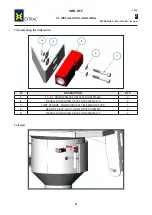

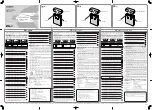

PERIODIC CHECKS

For further details on the lifting cross-bar refer to the related available on the WAMGROUP website.

Before every work shift

Check the safety devices to ensure they are present and intact.

After every work shift

Make sure that the passage of the material is free of residue; if this is not the case, clean carefully.

Every 100 hours of operation (every 2 weeks)

Check the condition of the FIBC support seal.

Every 200 hours of operation (monthly)

1

- Check the appearance of the structure, paying particular attention to the state of:

- welds in general;

- motovibrator fixing plate;

- damper support plates.

2

- Check that all bolts are correctly tightened, in par-ticular the motovibrator fixing bolts.

3

- Check the seal for cracks or splits.

4

- Check the dampers for signs of collapse (load deformation must not exceed 10% of nominal height).

5

- Check that the motovibrator is as clean as possible.

6

- Check the seals of the compressed air connections.

7

- Check to make sure the pneumatic cylinders of the pneumatic actuators kit (if present) are in perfect work-

ing order.

8

- Check earthing connection

Summary of Contents for SBB 125 C

Page 57: ......