See

the

table

of

contents

sec on

for

knife

changing

and

installa on.

Loosen

the

planing

head

locking

knob

(54

‐

21).

To

ini ally

begin

planing,

set

the

head

posi on

to

a

height

1/32”

less

than

the

di

‐

mension

of

the

stock

entering

the

machine.

One

‐

third

of

a

turn

on

the

eleva ng

handle

will

equal

1/32”.

Tighten

the

head

locking

knob.

Make

sure

the

chip

extractor

is

in

place,

the

front

lip

engaged

into

the

head

and

the

pin

is

fi

rmly

seated.

U lize

a

high,

square,

relieved

guide

when

planing

the

edge

of

stock

to

ensure

the

edge

will

be

reasonably

square.

A

relief

in

the

ver cal

wall

of

the

guide

reduces

fric on.

See

the

guide

sec on

for

a

picture

of

the

edge

guides.

THREAD LOCKING INFORMATION

A

medium

strength

thread

‐

locking

compound

used

on

some

parts

prone

to

loosen

with

vibra on.

Use

two

drops

on

the

thread

area

of

the

parts

listed

below.

P

‐

122

post

side

axle.

54

‐

16

Rest

pins.

54

‐

15

Pivot

screws.

A

small

tube

of

thread

locker

is

available

for

purchase.

Part

number

P

‐

242

Do

not

use

on

P

‐

124

in

‐

feed

axle,

or

on

P

‐

224,

out

‐

feed

axle.

THICKNESS

TYPE OF WOOD

DEPTH OF CUT

1”

Poplar

¼”

1”

Red Oak

3/16”

3”

White Pine

3/16”

3”

White Oak

1/8”

6”

Poplar

1/8”

6”

Red Oak

1/16”

Summary of Contents for 20210492060001

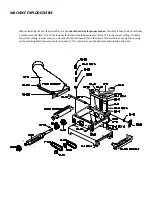

Page 19: ...ARBOR REMOVAL VIEW...

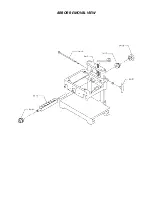

Page 20: ...Stand exploded diagram...

Page 22: ...Notes Maintenance Records...